User Manual

58

QL Series User Guide

Use the supplied cleaning pen or 70%

isopropyl alcohol on a cotton swab to

clean the print elements from end to end

(the print elements are located in the thin

gray line on the printhead).

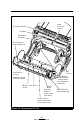

Printhead

(Figure 21)

Peel bar

(Figure 21)

Clean thoroughly with the cleaning pen

or 70% isopropyl alcohol and a cotton

swab.

Area Method Interval

As needed

After every five

rolls of media

(or more often,

if needed)

Platen

Roller

(Figure 21)

Rotate the platen roller and clean it

thoroughly with the cleaning pen or

70% isopropyl alcohol and a cotton

swab.

Units with linerless platens: Rotate

platen & clean bearing points only.

Avoid use of alcohol on the surface of

linerless platens!

Tear bar

(Figure 21)

Scraper,

Linerless units

only (Figure 21)

Clean thoroughly with the cleaning pen or

70% isopropyl alcohol and a cotton swab.

Clean thoroughly with the cleaning pen or

70% isopropyl alcohol and a cotton swab.

Water-dampened cloth

Brush/air blow. Ensure the Bar Sensor, Gap

Sensor and Label Present Sensor windows

are free of dust.

As needed

After every five

rolls of media

(or more often,

if needed)

After every five

rolls of media

(or more often,

if needed)

Linerless

media requires

more frequent

cleaning

Interior

(Figure 21)

Units with linerless platens:

Clean inside surfaces of media disks &

peeler bar rollers with the supplied cleaning

pen or 70% isopropyl alcohol on a cotton

swab.

Exterior

QL 320 Cleaning