Energy Meter Manual

Table Of Contents

- Introduction

- Notices

- Checking the Package

- Checking the Model and Suffix Codes

- Contents

- Chapter 1 Installation and Wiring

- 1.1 Installation with the ANSI 4-inch Round Form or JIS 110-square Instrument Size

- 1.2 Installation with the DIN 96-square Instrument Size

- 1.3 Wiring

- Crimping Terminal Recommendations

- Single-phase two-wire system (voltage input, current input, power supply)

- Single-phase three-wire system (voltage input, current input, power supply)

- Three-phase three-wire system (voltage input, current input, power supply)

- Three-phase four-wire system (voltage input, current input, power supply)

- Three-phase four-wire system (2.5 element) (voltage input, current input, power supply)

- Other Wiring

- 1.4 Attaching the Dust Cover and Terminal Cover

- Chapter 2 Preparations before Starting Measurement (Set up the PR300 First)

- Chapter 3 Parameter Setting Operations

- 3.1 Basic Parameter Setting Operations

- 3.2 Setting the VT and CT Ratios

- 3.3 Setting the Integrated Low-cut Power

- 3.4 Setting RS-485 Communication Conditions

- 3.5 Setting Ethernet Communication Conditions

- 3.6 Setting Pulse Output Conditions

- 3.7 Setting Analog Output Conditions

- 3.8 Setting Demand Measurement Conditions

- 3.9 Setting the Measured Value Display Pattern

- 3.10 Setting the “Indicator-out” Mode and Locking Parameters

- Chapter 4 Operation for Display of Measurement Items and Measurement Method

- 4.1 Measurement Items

- 4.2 Switching Display Pattern

- 4.3 Displaying Measured, Instantaneous, and Maximum/Minimum Values

- Example Display and Measuring Ranges of Active Power (Regenerative Power)

- Example Display and Measuring Ranges of Reactive Power

- Example Display and Measuring Ranges of Apparent Power

- Example Display and Measuring Ranges of Voltage

- Example Display and Measuring Ranges of Current

- Example Display and Measuring Ranges of Power Factor

- Example Display and Measuring Ranges of Frequency

- How to Switch between Instantaneous Value, Maximum Value, and Minimum Value

- 4.4 Phase Switching for Voltage and Current

- 4.5 Displaying Energy Values

- 4.6 Resetting Measured Values

- 4.7 Demand Measurement (Optional Measuring Function)

- Chapter 5 Troubleshooting

- Appendix

- Appendix 1 Specifications of PR300

- Measuring Function

- Power Items and Equations

- Input Specifications

- Digital Input Specifications

- Analog Output Specifications (additional output function)

- Pulse Output Specifications (additional output function)

- Demand Alarm Output Specifications (optional measuring function)

- Communication Specifications

- Standard Performance

- Safety and EMC Standards

- Environmental Conditions

- Mounting and Shape

- Appendix 2 System Reset

- Appendix 3 Parameter Map

- Appendix 4 Parameter List

- Appendix 5 Alphanumeric Characters Table for 7-segment LED

- Appendix 1 Specifications of PR300

- Index

- A

- C

- D

- E

- H

- I

- M

- O

- P

- R

- S

- T

- V

- W

- Wiring diagram

- Single-phase two-wire system

- Single-phase three-wire system

- Three-phase three-wire system

- Three-phase four-wire system

- Three-phase four-wire system (2.5 element)

- Analog output

- Demand alarm output

- Demand alarm release

- Ethernet communication

- Integration control signal

- Palse output

- RS-485 communication

- Wiring diagram

A-6

IM 77C01E01-01E

Appendix 1 Specifications of PR300

Modbus/TCP function

Code

03

06

08

16

Function

Reads data from multiple D registers

Writes data into D register

Performs loopback test

Writes data into multiple D registers

Description

Capable of reading data from up to 64 registers continuously.

Capable of writing data into one resiter.

Capable of performing a communication test.

Capable of writing data into up to 32 registers continuously.

Overview of Modbus/TCP protocol

PDU

The Simple Protocol Data Unit (PDU) is the same as

Modbus/RTU (Modbus protocol via serial communication).

MBAP Header Function code Data

The structure of the Modbus/TCP protocol is as follows:

Byte No

Description

0

Transaction ID

12

Protocol ID

34

Number of bytes

56

Unit ID

The Modbus Application Protocol Header (MBAP Header) is made of the

following seven bytes:

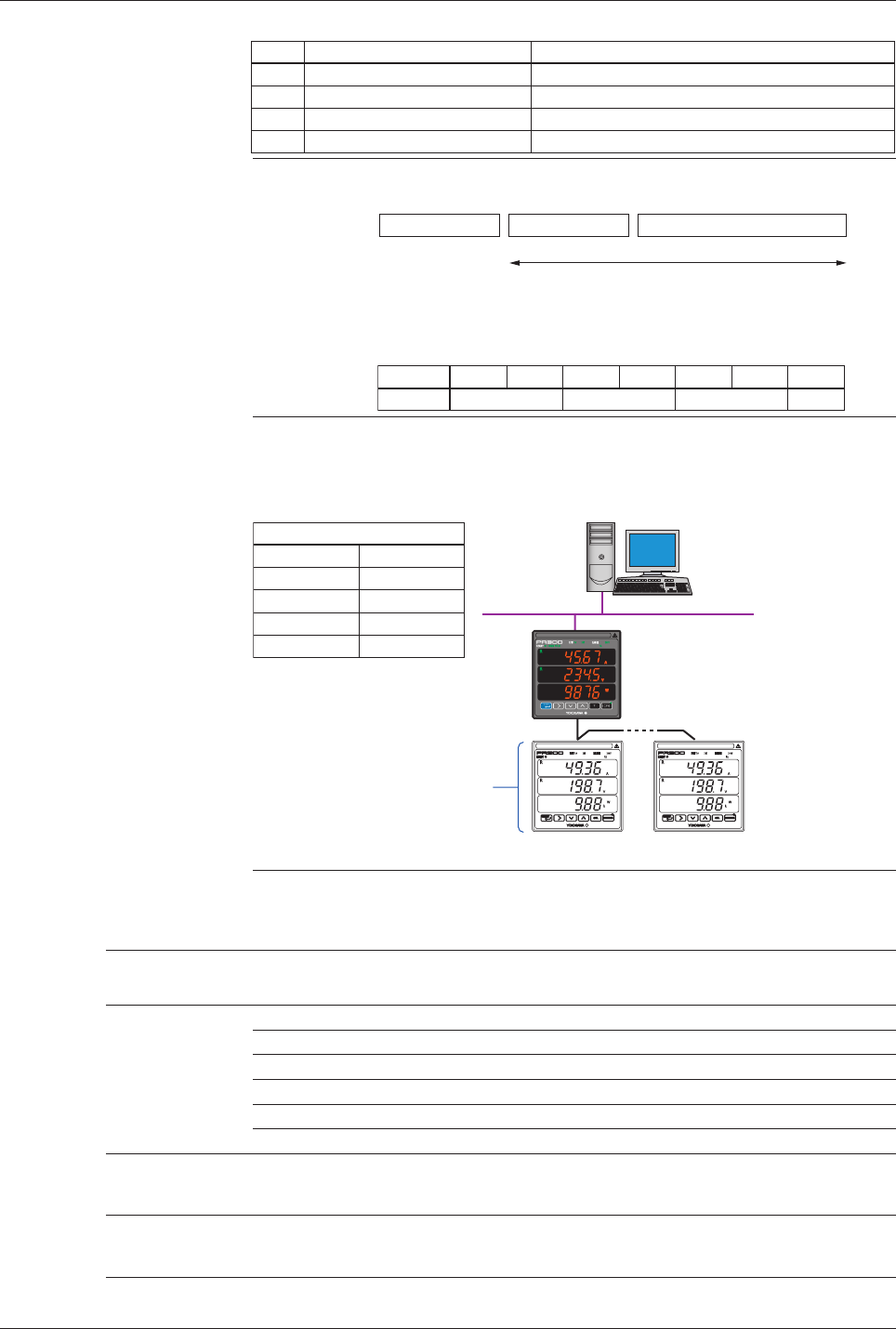

Ethernet - Serial gateway function

Equipped with an Ethernet communication connector and an RS-485 communication terminal, the

PR300 receives a Modbus/TCP command from Ethernet and relays it to the RS-485 communication

terminal. The PR300 allows connection to RS-485 serial communication devices (Modbus/RTU

protocol) via the network.

Higher-level device

IP address [192.168.1.1]

(arbitrary)

Ethernet

10BASE-T/100BASE-TX

Station number 01 (fixed)

IP address [192.168.1.2] (arbitrary)

PR300 (with Ethernet

communication function)

RS-485 connection

Station number 02

(arbitrary)

Station number 10

(arbitrary)

RS-485 serial communication device

Power monitor of POWERCERT Series

Digital indicating controller of GREEN Series

Signal conditioner of JUXTA Series

(Example)

RS-485 communication

Protocol

Baud rate

Parity

Stop bit

Data length

Modbus/RTU

9600bps

None, even, odd

1 bit

8 bits

(Note) If Ethernet communication is used, the RS-485 communication interface is

used specifically for the Ethernet-serial gateway function. Therefore, it is not

possible for a higher-level device such as a PC to access the PR300 via the

RS-485 communication interface.

Standard Performance

Accuracy rating

Active energy/optional active energy (Wh)

0.5% (EN60687 accuracy: Class 0.5 or equivalent)

Active power (W) 0.5% of F.S.

Voltage (V) 0.25% of F.S. (voltage rms)

Current (A) 0.25% of F.S. (current rms)

Frequency (Hz) 0.5Hz

Demand 0.5%

Calculation accuracy The value is calculated to 1 digit from the measured value for reactive energy, apparent

energy, reactive power, apparent power, power factor, or current.*

* Current is only for the 2.5-element measurement.

Backup upon power failure

The last integrated values obtained immediately before the power failure are held for active

energy, regenerative energy, reactive energy, and apparent energy.