Energy Meter Manual

Table Of Contents

- Introduction

- Notices

- Checking the Package

- Checking the Model and Suffix Codes

- Contents

- Chapter 1 Installation and Wiring

- 1.1 Installation with the ANSI 4-inch Round Form or JIS 110-square Instrument Size

- 1.2 Installation with the DIN 96-square Instrument Size

- 1.3 Wiring

- Crimping Terminal Recommendations

- Single-phase two-wire system (voltage input, current input, power supply)

- Single-phase three-wire system (voltage input, current input, power supply)

- Three-phase three-wire system (voltage input, current input, power supply)

- Three-phase four-wire system (voltage input, current input, power supply)

- Three-phase four-wire system (2.5 element) (voltage input, current input, power supply)

- Other Wiring

- 1.4 Attaching the Dust Cover and Terminal Cover

- Chapter 2 Preparations before Starting Measurement (Set up the PR300 First)

- Chapter 3 Parameter Setting Operations

- 3.1 Basic Parameter Setting Operations

- 3.2 Setting the VT and CT Ratios

- 3.3 Setting the Integrated Low-cut Power

- 3.4 Setting RS-485 Communication Conditions

- 3.5 Setting Ethernet Communication Conditions

- 3.6 Setting Pulse Output Conditions

- 3.7 Setting Analog Output Conditions

- 3.8 Setting Demand Measurement Conditions

- 3.9 Setting the Measured Value Display Pattern

- 3.10 Setting the “Indicator-out” Mode and Locking Parameters

- Chapter 4 Operation for Display of Measurement Items and Measurement Method

- 4.1 Measurement Items

- 4.2 Switching Display Pattern

- 4.3 Displaying Measured, Instantaneous, and Maximum/Minimum Values

- Example Display and Measuring Ranges of Active Power (Regenerative Power)

- Example Display and Measuring Ranges of Reactive Power

- Example Display and Measuring Ranges of Apparent Power

- Example Display and Measuring Ranges of Voltage

- Example Display and Measuring Ranges of Current

- Example Display and Measuring Ranges of Power Factor

- Example Display and Measuring Ranges of Frequency

- How to Switch between Instantaneous Value, Maximum Value, and Minimum Value

- 4.4 Phase Switching for Voltage and Current

- 4.5 Displaying Energy Values

- 4.6 Resetting Measured Values

- 4.7 Demand Measurement (Optional Measuring Function)

- Chapter 5 Troubleshooting

- Appendix

- Appendix 1 Specifications of PR300

- Measuring Function

- Power Items and Equations

- Input Specifications

- Digital Input Specifications

- Analog Output Specifications (additional output function)

- Pulse Output Specifications (additional output function)

- Demand Alarm Output Specifications (optional measuring function)

- Communication Specifications

- Standard Performance

- Safety and EMC Standards

- Environmental Conditions

- Mounting and Shape

- Appendix 2 System Reset

- Appendix 3 Parameter Map

- Appendix 4 Parameter List

- Appendix 5 Alphanumeric Characters Table for 7-segment LED

- Appendix 1 Specifications of PR300

- Index

- A

- C

- D

- E

- H

- I

- M

- O

- P

- R

- S

- T

- V

- W

- Wiring diagram

- Single-phase two-wire system

- Single-phase three-wire system

- Three-phase three-wire system

- Three-phase four-wire system

- Three-phase four-wire system (2.5 element)

- Analog output

- Demand alarm output

- Demand alarm release

- Ethernet communication

- Integration control signal

- Palse output

- RS-485 communication

- Wiring diagram

Operation for Display of Measurement Items and Measurement Method

4-9

IM 77C01E01-01E

1

2

3

4

5

A

4.5 Displaying Energy Values

Optional Integrating Function

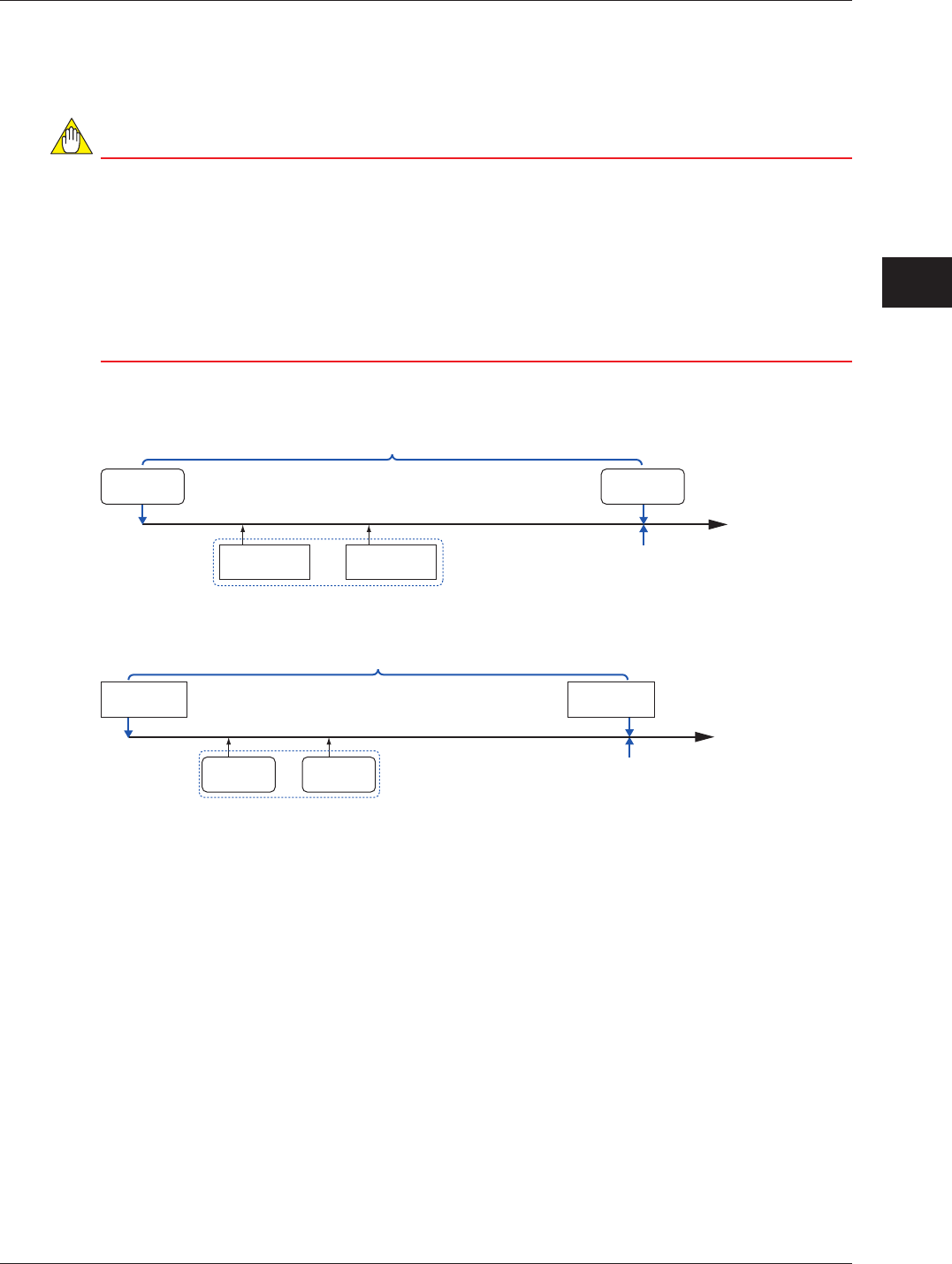

The optional integrating function integrates the active power while the control signal for optional

integration is activated (ON for activating and OFF for deactivating). The operation for this signal can be

performed via communication or by digital input.

NOTE

● The control signal for optional integration of the PR300 with the demand measuring function can be

controlled only via communication. It is not possible by digital input.

● The active power below the integrated low-cut power cannot be integrated.

● Once the control signal for optional integration is controlled via communication, communication is

the only means for controlling that signal until system reset* is performed. The same applies to

control by digital input.

* System reset can be performed by turning off/on the power supply for the PR300 or by executing

remote reset via communication.

● When the system is reset, the optional integrated value is reset to 0.

● If power failure occurs during integration, an optional integrated value is reset to 0.

Example operation of the control signal for optional integration via communication

Digital input

ON

Digital input

OFF

Start

command

Stop

command

Data update

Time

The active power during this time period is integrated.

These control

signals are invalid.

Example operation of the control signal for optional integration by digital input

Start

command

Digital input

ON

Digital input

OFF

The active power during this time period is integrated.

Stop

command

Data update

These control

signals are invalid.

Time

Digital input

Number of inputs: 1

Input signal: ON signal 4.5 to 25 V DC, OFF signal within 1 V DC

Maximum integrated value

99999 Wh (After the integrated value reaches this maximum value, it returns to “0.”)

Data update

When the control signal for optional integration is turned off and then turned on:

The displayed measured value is reset to 0, and integration starts. The integrated value before

resetting (previous value) can be confirmed via communication.

When the control signal for optional integration is turned on for a while and turned off later:

The displayed measured value is the integrated value. This value display is retained until the control

signal for optional integration is turned on again.