Energy Meter Manual

Table Of Contents

- Introduction

- Notices

- Checking the Package

- Checking the Model and Suffix Codes

- Contents

- Chapter 1 Installation and Wiring

- 1.1 Installation with the ANSI 4-inch Round Form or JIS 110-square Instrument Size

- 1.2 Installation with the DIN 96-square Instrument Size

- 1.3 Wiring

- Crimping Terminal Recommendations

- Single-phase two-wire system (voltage input, current input, power supply)

- Single-phase three-wire system (voltage input, current input, power supply)

- Three-phase three-wire system (voltage input, current input, power supply)

- Three-phase four-wire system (voltage input, current input, power supply)

- Three-phase four-wire system (2.5 element) (voltage input, current input, power supply)

- Other Wiring

- 1.4 Attaching the Dust Cover and Terminal Cover

- Chapter 2 Preparations before Starting Measurement (Set up the PR300 First)

- Chapter 3 Parameter Setting Operations

- 3.1 Basic Parameter Setting Operations

- 3.2 Setting the VT and CT Ratios

- 3.3 Setting the Integrated Low-cut Power

- 3.4 Setting RS-485 Communication Conditions

- 3.5 Setting Ethernet Communication Conditions

- 3.6 Setting Pulse Output Conditions

- 3.7 Setting Analog Output Conditions

- 3.8 Setting Demand Measurement Conditions

- 3.9 Setting the Measured Value Display Pattern

- 3.10 Setting the “Indicator-out” Mode and Locking Parameters

- Chapter 4 Operation for Display of Measurement Items and Measurement Method

- 4.1 Measurement Items

- 4.2 Switching Display Pattern

- 4.3 Displaying Measured, Instantaneous, and Maximum/Minimum Values

- Example Display and Measuring Ranges of Active Power (Regenerative Power)

- Example Display and Measuring Ranges of Reactive Power

- Example Display and Measuring Ranges of Apparent Power

- Example Display and Measuring Ranges of Voltage

- Example Display and Measuring Ranges of Current

- Example Display and Measuring Ranges of Power Factor

- Example Display and Measuring Ranges of Frequency

- How to Switch between Instantaneous Value, Maximum Value, and Minimum Value

- 4.4 Phase Switching for Voltage and Current

- 4.5 Displaying Energy Values

- 4.6 Resetting Measured Values

- 4.7 Demand Measurement (Optional Measuring Function)

- Chapter 5 Troubleshooting

- Appendix

- Appendix 1 Specifications of PR300

- Measuring Function

- Power Items and Equations

- Input Specifications

- Digital Input Specifications

- Analog Output Specifications (additional output function)

- Pulse Output Specifications (additional output function)

- Demand Alarm Output Specifications (optional measuring function)

- Communication Specifications

- Standard Performance

- Safety and EMC Standards

- Environmental Conditions

- Mounting and Shape

- Appendix 2 System Reset

- Appendix 3 Parameter Map

- Appendix 4 Parameter List

- Appendix 5 Alphanumeric Characters Table for 7-segment LED

- Appendix 1 Specifications of PR300

- Index

- A

- C

- D

- E

- H

- I

- M

- O

- P

- R

- S

- T

- V

- W

- Wiring diagram

- Single-phase two-wire system

- Single-phase three-wire system

- Three-phase three-wire system

- Three-phase four-wire system

- Three-phase four-wire system (2.5 element)

- Analog output

- Demand alarm output

- Demand alarm release

- Ethernet communication

- Integration control signal

- Palse output

- RS-485 communication

- Wiring diagram

1-5

IM 77C01E01-01E

1

1

2

3

4

5

A

I

Installation and Wiring

1.3 Wiring

WARNING

● As there is a danger of electric shock, turn off the power supply and check that the cables to be

connected are not conducting electricity before carrying out the wiring procedure.

● For safety, be sure to install a circuit breaker switch that conforms to IEC60947 near the PR300 so

as to be operated easily, and clearly indicate that the device is used to de-energize the PR300.

● The wiring procedure for the PR300 should be carried out by a qualified person (an electrician etc.)

with knowledge of electrical matters and who has actual experience.

● Install a current transformer (CT) inside a panel when using a conduit for wiring.

● Use a UL Listed Panel only for the panel on which the PR300 is installed.

● If the voltage is below 600 V AC, it is possible to connect the PR300 directly without using a voltage

transformer (VT) and if the current is below 5 A AC, it is possible to do so without using a current

transformer (CT). However, in order to use the PR300 safely, the use of VT and CT is recom-

mended. Use a UL Listed VT and CT for the PR300.

● Perform wiring for the voltage and current input in the same circuit.

● Check the following before turning on the power. Using the PR300 beyond the stated specifications

may cause it to heat up and burn out.

• Check that the power supply voltage, input voltage, and input current values to be applied to the

PR300 agree with its specifications.

• Check that the external wiring is connected to the terminals in accordance with the specifica-

tions.

● Do not touch the screws in locations (a) to (f) shown in the wiring diagrams. They are an essential

part of the structure of the PR300. Loosening or tightening them may result in a malfunction or

failure of the PR300.

● Be sure to attach the terminal cover to prevent electric shock (refer to Section 1.4) .

NOTE

● When attaching the terminal cover

Since the terminal cover of PR300 has the structure of preventing electric shock, the terminal cover

cannot be attached after completing all wiring. Refer to Section 1.4, “Attaching the Dust Cover and

Terminal Cover” before wiring.

(1) Attach the terminal cover after completing the wiring to the terminals 2, 4, 6, 8, 23, 24, and 25.

(2) Execute the wiring to the terminals other than those mentioned above after attaching the

terminal cover.

If the dust cover is required, attach it before attaching the terminal cover.

●

Do not ground the input circuit when connecting voltage and current directly without using VT and CT.

Carry out the wiring referring to the diagrams on pages 1-6, 1-7, and 1-8. The wiring for voltage input,

current input, and power supply is M4 screw terminal connection. For other wiring it is M3 screw terminal

connection. The connector for connecting to the Ethernet is RJ45.

Use strand wires for the wiring. Wiring cables with a nominal cross-sectional area of 1.25 mm

2

or thicker

are recommended for voltage/current input and power supply; cables with a nominal cross-sectional area

of 0.5 mm

2

or thicker are recommended for other signals.

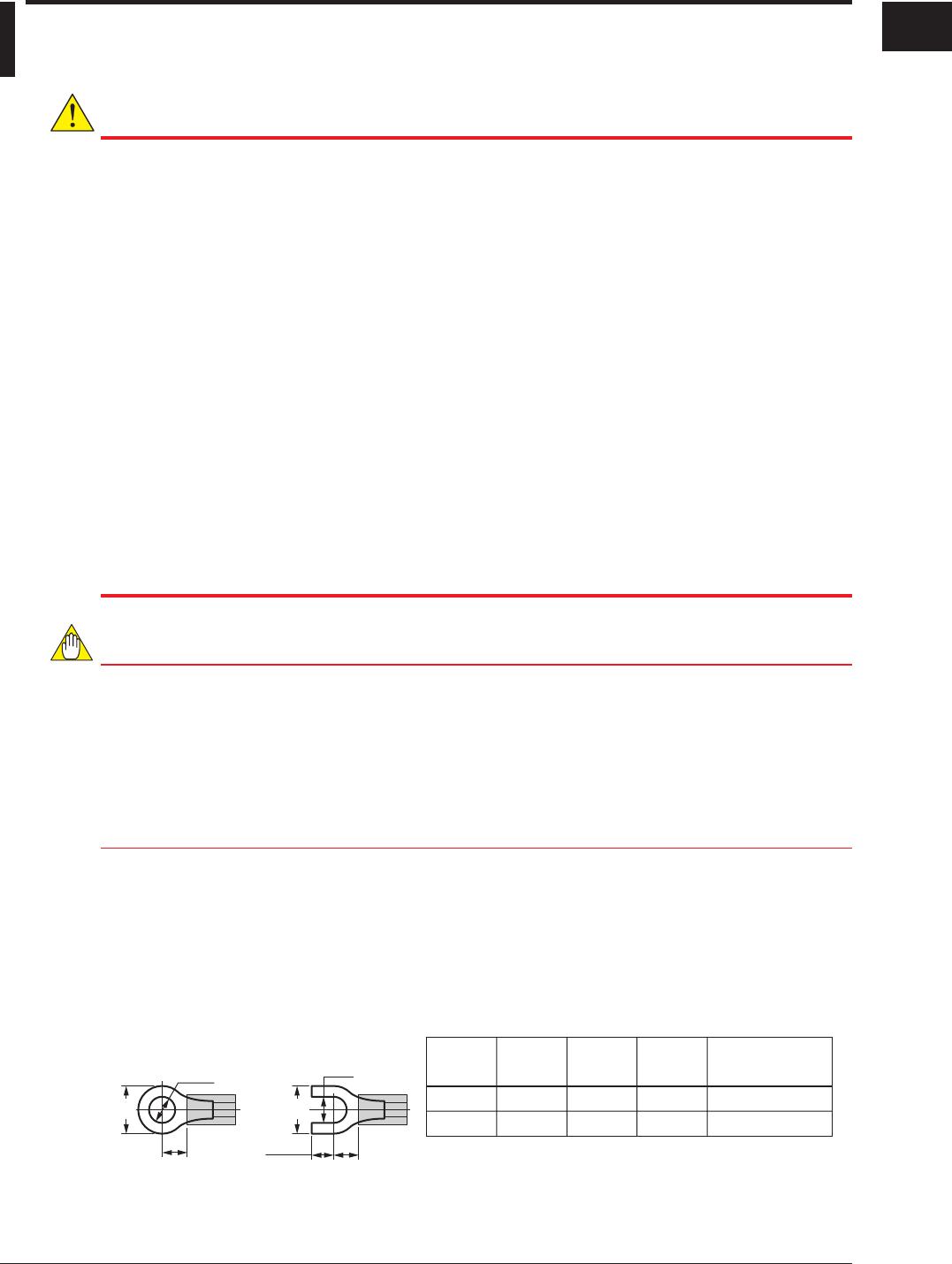

Crimping Terminal Recommendations

(A)

(F)

(F)

4.7 max.

(ød)

M4

M3

4.4 max.

3.3 max.

7.0 max.

5.8 max.

7.8 max.

6.7 max.

1.2 N•m

0.6 N•m

ød (mm)

Applicable

terminals

A

(mm)

F

(mm)

Recommended

tightening torque

Ring tongue

terminal

Spade tongue

terminal

(A)

(ød)

Applicable wire size: 1.04 to 2.63 mm

2

for M4, 0.25 to 1.65 mm

2

for M3