Instruction Manual

Table Of Contents

- 1. Introduction

- 2. Safety Precautions

- 3. FOUNDATION FIELDBUS

- 3-1 About Foundation Fieldbus

- 3-2 Getting started

- 3-3 Configuration

- 3-4 In-process operation

- 3-5 Device status

- 3-6 List of parameters for each block of the EXA

- 3-7 Application setting and change of basic parameters

- 3-8 Operation of each parameter in failure mode

- 4. PROFIBUS

- APPENDIX 1. LINK MASTER FUNCTIONS

- Revision Record

- Supplement

IM 12A00A01-61E

3-38 Foundation Fieldbus

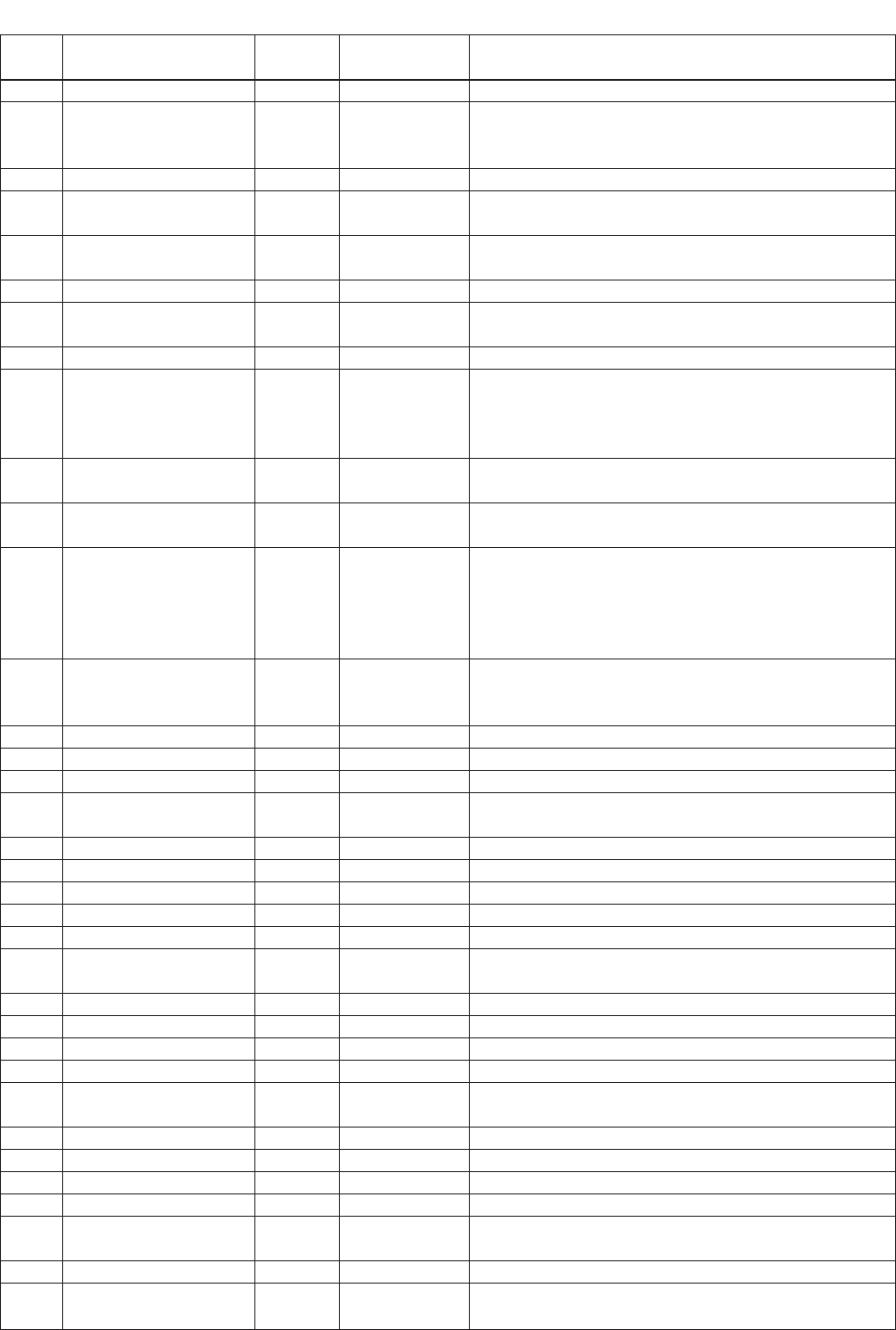

3-6-3-3 Transducer Block ISC202

Index Parameter name Factory Valid Description

Default Range

2000 BLOCK HEADER TAG: “TB” General information about thefunction block

2001 ST_REV - - The revision level of the static data associated with the function

block. The revision value will be incremented each time a static

parameter value in the block is changed

2002 TAG_DESC “ “ The user description of the intended application of the block

2003 STRATEGY 1 The strategy field can be used to identify grouping of blocks.

This data is not checked or processed by the block

2004 ALERT_KEY 1 The identification number of the plant unit. This information may be

used in the host for sorting alarms, etc.

2005 MODE_BLK AUTO The actual, target, permitted, and normal modes of the block

2006 BLOCK_ERR - This parameter reflects the error status associated with a block. It

is a bit-string, so that multiple errors can be shown

2007 UPDATE_EVT - The alert is generated by any change to the static data.

2008 BLOCK_ALM - The block alarm is used for all configuration error, hardware

connection failure or system problems in the block. The cause of

the alert is entered in the subcode field. The first alert to become

active will set Active status in Status attribute.

2009 TRANSDUCER_DIRECTORY A directory that specifies the number and starting indices of the

transducers.

2010 TRANSDUCER Conductivity conductivity Conductivity transducer block

_TYPE Transmitter

2011 XD_ERROR - The error code in transducer:

No failure,

Electronics failure,

I/O failure,

Mechanical failure

2012 COLLECTION_DIRECTORY - A directory that specifies the number, starting indices and DD item

Ids of the data collection in each transducer within a transducer

block

2013 PRIMARY_VALUE_TYPE conductivity, conductivity Type of measurement represented by primary value

2014 PRIMARY_VALUE - 0 to 2 S/cm Primary value of the instrument is Conductivity

2015 PRIMARY_VALUE_RANGE 0 to 2 S/cm 0 to 2 S/cm The range of the instrument (can not change)

2016 SENSOR_CONST 1.88 0.2 to 19.99 cm

-1

The conductivity cell has a specific cell constant determined by the

dimensions of the cell

2017 CAL_POINT_HI 1.999 0 to 2 S/cm Highest calibration point

2018 CAL_POINT_LO 0 0 to 2 S/cm Lower calibration point

2019 CAL_MIN_SPAN 0,0001 > 0,0001 S/cm Minimum span between two calibration points

2020 SENSOR_CAL_METHOD - 1point, 2point not used

2021 SENSOR_CAL_DATE - till 2104 Date the sensor was last calibrated

2022 SECONDARY_VALUE - -20 to 140 ºC , Temperature value

0 to 280ºF

2023 SECONDARY_VALUE_UNIT ºC ºC, ºF Temperature unit

2024 SENSOR_TEMP automatic automatic auto when a temperature element is available

2025 SENSOR_TEMP_MAN_VALUE - - No manual temp. value possible. Always automatic

2026 SENSOR_TYPE _TEMP NTC30K Pt1000, NTC30k Temperature element used:

2027 SENSOR_CONNECTION_ 2 2 Only 2-wire connections supported

TEMP

2028 SENSOR_TYPE_COND toroidal toroidal Non contacting toroidal sensor.

2029 SENSOR_OHMS - Actual cell resistance

2030 XD_MAN_ID “ “

2031 TEMPERATURE_COEFF 2.1 0 to 3.5%/ºC (%/ºF) Process temperature compensation factor

2032 CONCENTRATION - Conductivity combined with temperature can be directly related to the

concentration. Concentraion isexpressed in percentage

2033 TERTIARY_VALUE - 0 to 2 S/cm Second compensated conductivity value

2034 REFERENCE_TEMPERATURE 25 0 to 100 ºC Conductivity can be process compensated to a standard

(32 to 212ºF) reference temperature. Mostly 20ºC or 25ºC is used