Instruction Manual

Table Of Contents

- 1. Introduction

- 2. Safety Precautions

- 3. FOUNDATION FIELDBUS

- 3-1 About Foundation Fieldbus

- 3-2 Getting started

- 3-3 Configuration

- 3-4 In-process operation

- 3-5 Device status

- 3-6 List of parameters for each block of the EXA

- 3-7 Application setting and change of basic parameters

- 3-8 Operation of each parameter in failure mode

- 4. PROFIBUS

- APPENDIX 1. LINK MASTER FUNCTIONS

- Revision Record

- Supplement

IM 12A00A01-61E

Foundation Fieldbus 3-33

3-33

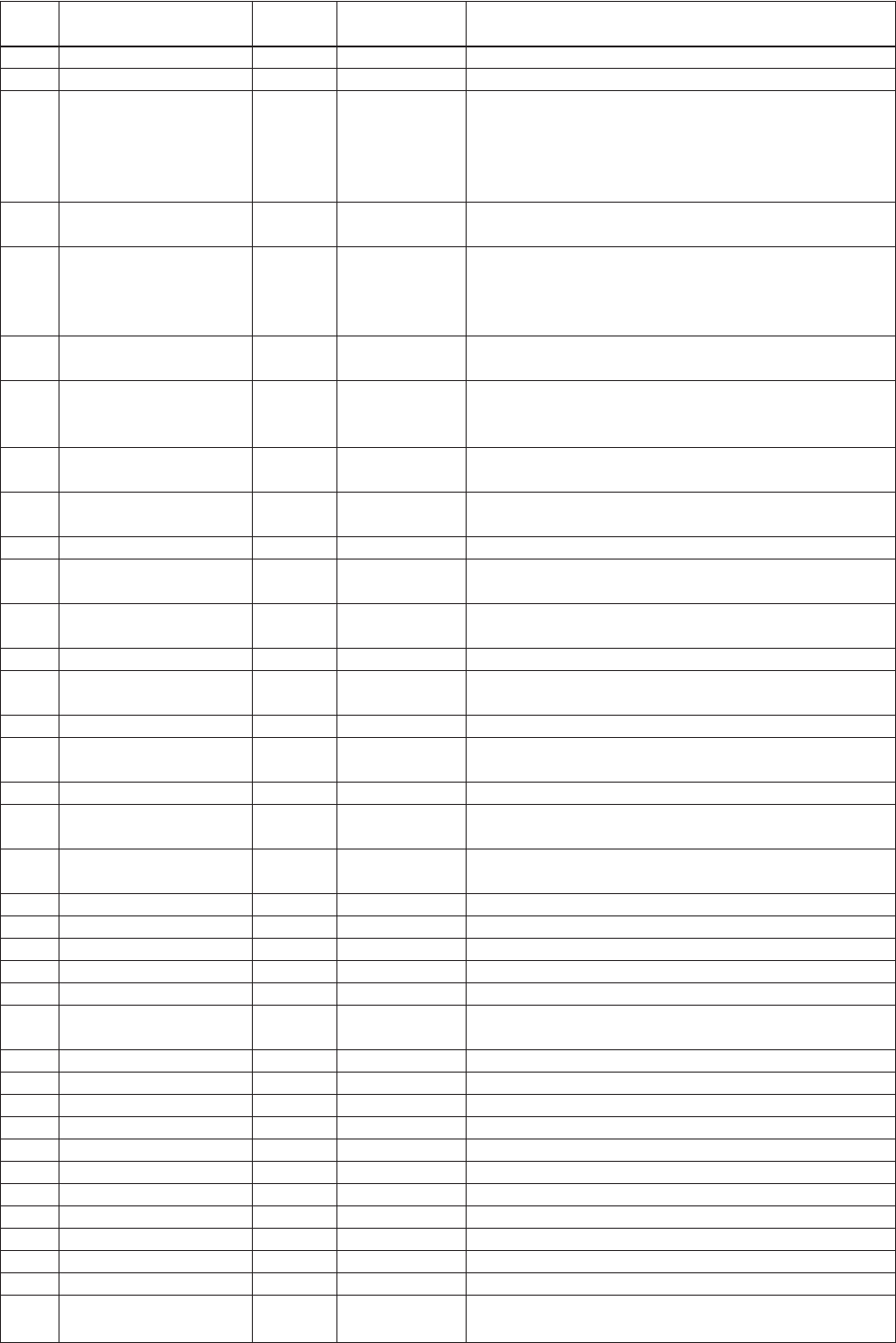

Index Parameter name Factory Valid Description

Default Range

2029 SECONDARY_VALUE_UNIT °C °C, °F Temperature unit

2030 SENSOR_TEMP_COMP automatic Off, manual, Select off when no temperature compensation is required.

automatic Select manual when no temperature element is available and the

temperature is stable and select auto when a temperature element

is available

pH: man + auto

orp: off + auto

2031 SENSOR_TEMP_MAN_VALUE 25 -30 to 140°C, manual temperature value

-20 to 280°F

2032 SENSOR_TYPE_TEMP Pt1000 Pt1000, Pt100, Temperature element used:

5k1, 3kBalco,

8k55, 350,

NTC10k, 6k8

2033 SENSOR_CONNECTION 2 2 Only 2-wire connections supported

_TEMP

2034 TERTIARY_VALUE_TYPE None None, ORP, rH When a metal electrode is used in combination with a glass and

reference electrode one has the possibility to measure a tertiary

value:

2035 TERTIARY_VALUE - -1500 to 1500 mV, The third value is expresed in mV or rH units

0 to 55 rH

2036 TERTIARY_VALUE_RANGE -1500 -1500 to 1500 mV, The high and low range limits for the tertiary value.

to 1500 0 to 55 rH

2037 TERTIARY_ZERO 0 -120 to 120mV Redox offset can be set in mV.

2038 GLASS_IMPEDANCE - 1MΩ to 2 GΩ (HI) Value that indicates the state of the glass membrane.

1kΩ to 1MΩ (LO) Depending on the jumper setting the range is set to High or Low.

2039 REFERENCE_IMPEDANCE - 1MΩ to 2 GΩ (HI) Value that indicates the state of the reference system.

1kΩ to 1MΩ (LO) Depending on the jumper setting the range is set to High or Low.

2040 ALARM_SUM -

2041 DEV_ALARM - Device Alarm is used to give the status of the transmitter. Device_

status in RB displays the device Alarms.

2042 LOGBOOK1_RESET - Reset the pointer to the first (oldest) event in logbook 1.

2043 LOGBOOK1_EVENT - Event whereto the pointer is referenced. When parameter is read,

the pointer is increased by one.

2044 LOGBOOK2_RESET - Reset the pointer to the first (oldest) event in logbook 2.

2045 LOGBOOK2_EVENT - Event whereto the pointer is referenced. When parameter is read,

the pointer is increased by one.

2046 LOGBOOK_CONFIG - Per event one can decide whether it should be logged and in which

logbook (1 or 2) it should be logged.

2047 TEST_1 - Service parameter

.... - 2048 to 2058 are, like 2047 and 2059, service parameters

2059 TEST_13 - Service parameter

2060 STABLE_TIME 5 5.0 to 30.0 Stability criteria used during automatic calibration.

2061 STABLE_VALUE 0.02 0.01 to 1.0 Stability criteria used during automatic calibration.

2062 CALL_MAINT_TIME_

COUNTDOWN 250 1 to 250 The remaining days till maintenance is required.

2063 CALL_MAINT_TIME_RELOAD 250 1 to 250 The interval of the maintenance timer.

2064

INPUT_1_IMPEDANCE_LO_LIM

1.00E6 100.0 to 1.0E9 The low limit of the input 1 impedance.

2065

INPUT_1_IMPEDANCE_HI_LIM

1.00E9 100.0 to 1.0E9 The high limit of the input 1 impedance.

2066

INPUT_2_IMPEDANCE_LO_LIM

100 100.0 to 1.0E9 The low limit of the input 2 impedance.

2067

INPUT_2_IMPEDANCE_HI_LIM

200000 100.0 to 1.0E9 The high limit of the input 2 impedance.

2068 BUFFER1_ID 4 0 to 9 The ID of buffer one, used during automatic calibration.

2069 BUFFER1 4.0 -2.0 to 16.0 The first user defined calibration buffer.

2070 BUFFER2_ID 7 0 to 9 The ID of buffer two, used during automatic calibration.

2071 BUFFER2 7.0 -2.0 to 16.0 The second user defined calibration buffer.

2072 BUFFER3_ID 9 0 to 9 The ID of buffer three, used during automatic calibration.

2073 BUFFER3 9.0 -2.0 to 16.0 The third user defined calibration buffer.

2074

TEMPERATURE_COEFFICIENT

0.0 -1.0 to 1.0 The temperature coefficient of the primary value.

-100.0 to 100.0