Installation Guide

1190828-UIM-G-0915

12 Johnson Controls Unitary Products

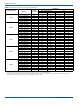

TABLE 9:

Air Flow Data (CFM)

1

MP Models CM Models

Blower

Motor Speed

External Static Pressure (in. wc.)

0.10 0.20 0.30 0.40 0.50 0.60 0.70

208 Volts

MP08B

CM18B

High 975 965 953 926 889

772 724

Medium 729 719 700 643 614

540 354

Low 576 561 501 455 407

289 209

CM24B

High 950 944 927 907 876

838 742

Medium 713 703 686 656 591

533 478

Low 560 546 511 448 398

294 208

MP12B

CM30B

High 1459 1410 1342 1275 1200

1129 1022

Medium 1241 1210 1156 1110 1044

1002 917

Low 992 965 940 911 867

822 758

CM36B

High 1487 1438 1383 1315 1245

1150 1073

Medium 1226 1202 1166 1119 1079

1007 945

Low 959 950 925 892 866

818 716

MP14D

CM30D

High 1944 1891 1832 1767 1693

1594 1303

Medium 1518 1494 1470 1425 1377

1186 1071

Low 1208 1198 1180 1155 1019

968 830

CM36D

High 1967 1920 1848 1781 1710

1623 1532

Medium 1520 1508 1486 1446 1398

1203 1101

Low 1207 1202 1176 1156 1028

970 885

CM42D

High 1949 1912 1854 1791 1715

1645 1358

Medium 1538 1521 1492 1458 1406

1265 1144

Low 1197 1190 1179 1128 1052

998 903

MP16C

CM36C

High 1776 1709 1646 1573 1491

1328 1171

Medium 1591 1545 1486 1424 1300

1173 1066

Low 1360 1331 1285 1194 1097

1027 941

CM42C

High 1746 1687 1616 1536 1386

1265 1147

Medium 1564 1507 1451 1388 1246

1148 998

Low 1339 1301 1258 1136 1052

994 876

CM48C

High 1817 1756 1678 1599 1511

1296 1120

Medium 1673 1618 1542 1477 1349

1138 915

Low 1448 1419 1362 1281 1136

1001 948

MP20D

CM42D

High 2035 1994 1922 1858 1781

1658 1562

Medium 1849 1819 1771 1694 1650

1575 1364

Low 1679 1654 1624 1578 1526

1339 1263

CM48D

High 2061 2001 1937 1871 1780

1684 1570

Medium 1867 1835 1786 1727 1653

1563 1328

Low 1678 1657 1615 1572 1518

1441 1235

CM60D

High 2021 1979 1897 1833 1751

1668 1521

Medium 1852 1811 1758 1697 1639

1547 1389

Low 1646 1630 1596 1555 1491

1384 1247

CM64D

High 1867 1832 1784 1729 1652

1572 1462

Medium 1498 1484 1443 1411 1361

1233 1138

Low 1128 1122 1115 1096 1020

967 893

1. Air handler units have been tested to UL 1995 / CSA 22.2 standards up to 0.50" wc. external static pressure.

Dry coil conditions only, tested without filters.

For optimal performance, external static pressures of 0.2" to 0.5" are recommended. Applications above 0.5" are not recommended.