Installation Guide

1190828-UIM-G-0915

6 Johnson Controls Unitary Products

DUCT FLANGES

Three duct flanges are provided to assist in positioning and attaching

duct work to the air handler. These flanges are included in the unit parts

bag. With the screws from the parts bag, install one of the duct flanges.

Duct flanges have holes on both legs with one leg longer than the other.

The longer leg can be used to mate against the air handler so that

different thicknesses of duct board can be made flush with the outer

surface of the air handler. Repeat the procedure for the other two

flanges. Refer to Figure 7. If the flanges are not used, they may be

discarded.

UNIT CONNECTIONS

There are several ways to handle the supply and return air duct

connections. The location and sizing of the connections depends on the

situation and the method best suited to the installation. Upflow,

horizontal or downflow applications may be used.

The supply air duct should be properly sized by use of a transition to

match unit opening. Refer to Table 1 for air handler unit inlet and outlet

dimensions.

Duct work that is not designed to match the supply air opening can

cause turbulence inside the plenum. This turbulence can change the air

flow patterns across the electric heater limit switches. If the factory

suggested transition cannot be fabricated, it is recommended that a

block off plate (approximately 8" high and running the full width of the

plenum) be attached to the supply opening. Refer to Figure 8 as a

visual aid. The use of this block off plate will enable better air circulation

across the limit switches.

AIR FILTERS

Return air filters are required and must be field supplied. Filtration must

be accomplished external to the unit.

.

SECTION V: ELECTRIC HEATER

INSTALLATION

If the air handler requires electric heat, install the electric heat kit

according to the installation instructions included with the kit. After

installing the kit, mark the air handler nameplate to designate the heater

kit that was installed. If no heater is installed, mark the name plate

appropriately to indicate that no heat kit is installed.

Use only 6HK Revision C or later heater kits, as listed on air handler

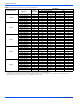

name plate and in these instructions. Use data from Tables 4 through 9

for information on required minimum motor speed tap to be used for

heating operation, maximum over-current protection device required as

listed for combination of air handler and heater kit.

FIGURE 7: Duct Attachment

FIGURE 8: Duct Work Transition

A0445-001

DUCT FLANGES

(Shipped in bag with unit)

A0332-001

RECOMMENDED

TRANSITION

SUGGESTED LOCATION

OF BLOCK OFF PLATE

CAUTION

Use 1/2” screws to connect duct work to unit. Longer screws will

pierce the drain pan and cause leakage. If pilot holes are drilled, drill

only though field duct and unit bottom duct flange.

CAUTION

Equipment should never be operated without filters.

FIGURE 9: Blower Delay Control Board

!

!

PSC CONTROLBOARD

A0356-001