Installation Guide

1190828-UIM-G-0915

Johnson Controls Unitary Products 5

SECTION IV: DUCT WORK AND

CONNECTIONS

Air supply and return may be handled in one of several ways best

suited to the installation. Upflow, horizontal or downflow applications

may be used.

The vast majority of problems encountered with heating and cooling

systems can be linked to improperly designed or installed duct systems.

It is therefore highly important to the success of an installation that the

duct system be properly designed and installed.

When installing a central air return grille in or near the living space, it is

advisable to design the duct work so that the grille is not in direct line

with the opening in the unit. One or two elbows and acoustical duct liner

assures a quieter system. Operation where return air duct is short or

where sound may be a problem, acoustical duct liner should be used

inside the duct. If electric heat is used, non-flammable material must be

used.

Use flexible duct connectors to minimize the transmission of vibration/

noise into the conditioned space. Never fasten duct work directly to the

structure.

Insulation of duct work is a must where it runs through an unheated

space during the heating season or through an uncooled space during

the cooling season. The use of a vapor barrier is recommended to

prevent absorption of moisture from the surrounding air into the

insulation.

The supply air duct should be properly sized by use of a transition to

match unit opening. All ducts should be suspended using flexible

hangers and never fastened directly to the structure.

Duct work should be fabricated and installed in accordance with local

and/or national codes. This includes the standards of the National Fire

Protection Association for Installation of Air-Conditioning and

Ventilating Systems, NFPA No. 90B. Duct systems should be designed

in accordance with the Air Conditioning Contractors of America (ACCA)

– Manual D.

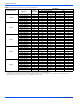

HORIZONTAL SUSPENSION

For suspension of these units in horizontal applications, it is recom-

mended to use angle steel support brackets with threaded rods, sup-

porting the units from the bottom, at the locations shown in Figure 6.

WARNING

Use only 1/2” screws to connect duct work to bottom of unit.

WARNING

Do not bring in return air from a location which could introduce haz-

ardous substances into the airflow.

Use 1/2” screws to connect duct work to cabinet. If pilot holes are

drilled, drill only through field duct and unit flange.

CAUTION

This unit is not designed for non-ducted (freeblow) applications. Do

not operate without duct work attached to unit.

Equipment should never be operated without filters.

!

!

!

(Cabinet Width) Position

Dimensions

HX

(17-1/2”) Horizontal Left 40-1/2” – 47-1/2” 20”

(21” thru 24-1/2”) Horizontal Left 43-1/2” – 55-1/2” 21”

(17-1/2”) Horizontal Right 40-1/2” – 47-1/2” 20”

(21” thru 24-1/2”) Horizontal Right 43-1/2” – 55-1/2” 21”

FIGURE 6: Typical Horizontal Installation

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTAL RIGHT

2”

1-1/2”

MIN. 1-1/2” x 1-1/2”

Angle Recommended

length 26” minimum

with 2” clearance on both

sides of Air Handler

MIN. 3/8”

THREADED ROD

H

1”

1-1/2”

A0348-002

X

H

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTAL LEFT

X

TIE PLATE