User guide

1

Symbols

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

CAUTION: DO NOT

connect this brewer to hot

water. The inlet valve is

not rated for hot water.

CAUTION: Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions can result in injury or the

voiding of the warranty.

Model

•D1000GT

3. Connect the unit to electrical outlet with appropriate amperage rating (see serial tag on machine).

4.Oncepowerhasbeensuppliedtotheunit,ipthetoggleswitchtothe‘ON’position(locatedontherearof

theunit),thewatertankwillbegintoll.Whenthewaterlevelinthetankreachestheprobe,theheating

element(s) will turn on.

5. Water in the heating tank will require approximately a half hour before reaching operating temperature (factory

settingof200°F).Whereapplicable,turnontheUniversalControlModule(UCM).Whentheunitreaches

operating temperature, it will display “READY TO BREW”.

Wilbur Curtis Company, inC.

ServiceManual–D1000GTAirpotBrewer

Important Safeguards & Symbols

This appliance is designed for commercial use. Any servicing other than cleaning and preventive maintenance

should be performed by an authorized Wilbur Curtis service technician.

•DoNOTimmersetheunitinwateroranyotherliquid

•Toreducetheriskofreorelectricshock,doNOTopenservicepanels.Nouserserviceablepartsinside.

•Keephandsandotheritemsawayfromhotsurfacesofunitduringoperation.

•Nevercleanwithscouringpowders,bleachorharshchemicals.

The Curtis G3 airpot brewer is Factory Pre-Set and Ready to Go… Right from the Box.

Following are the Factory Settings for Curtis airpot brewers:

•BrewTemperature=200°F

•BrewVolume=Settovesselrequirements(75oz).

System Requirements:

•WaterSource20–90PSI(minimumowrateof1GPM)

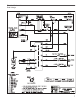

•Electrical:Seeattachedschematicforstandardmodelorvisitwww.wilburcurtis.comforyourmodel.

Setup Steps

1. The unit should be level (left to right - front to back), on a secure surface.

2. Connectthewaterlinetothewaterinletttingontherearoftheunit.Watervolumeowtothemachine

shouldbeconsistent.Usetubingsizedsufcientlytoprovideaminimumowrateof1GPM.

NOTE:Awaterltrationsystemmustbeusedtohelpmaintaintrouble-freeoperation.Air must be purged

from the cartridge prior to connection to equipment. In areas with extremely hard water, we highly

recommendtheuseofaCurtisapprovedwaterlter.Forourfulllineoflters,pleaselogontowww.wilbur-

curtis.com.

NSF International requires the following water connection:

1. A quick disconnect or additional coiled tubing (at least 2x the depth of the unit) is required so that the unit

can be moved for cleaning.

2. Thisunitmustbeinstalledwithadequatebackowprotectiontocomplywithapplicablefederal,stateand

local codes.

3.Waterpipeconnectionsandxturesdirectlyconnectedtoaportablewatersupplyshallbesized,installed

andmaintainedinaccordancewithfederal,state,andlocalcodes.

Forthelatestspecicationsandinformationgotowww.wilburcurtis.com

Technical Support: 1-800-995-0417 M-F 5:30am-4:00pm PT

Email: techsupport@wilburcurtis.com

ISO 9001:2008 REGISTERED

WILBURCURTISCO.,INC.

6913 West Acco Street

Montebello,CA90640-5403

For the latest information go to

www.wilburcurtis.com

Tel: 800-421-6150

Fax: 323-837-2410