Use and Care Manual

14

OPERATION

MITER GAUGE - DISC SANDER

A miter-gauge is supplied with your sander, and can be used on the disc table. The miter gauge head can be set

anywhere up to 60º (right or left) by loosening the lock-knob, setting the miter gauge head to the desired angle,

and retightening the lock-knob.

SANDING SMALL END GRAIN AND OTHER SMALL SURFACES USING MITER GAUGE

Use of the miter gauge is recommended for sanding small end surfaces on the sanding disc.

Note: Always move the workpiece across the sanding disc from the left side towards the right side, and be sure to

hold the workpiece down tightly onto the table surface.

MAINTENANCE

WARNING: For your own safety, turn the switch OFF and remove the plug from

the electrical outlet before adjusting or performing maintenance or lubrication work

on the belt/disc sander.

Before using, check to make sure parts are not damaged, missing, or worn. Check

for alignment of moving parts, binding of moving parts, improper mounting, or any

other conditions that may affect the sander operation. If any of these conditions ex-

ist, do not use the sander until parts are replaced or the sander is properly repaired.

Frequently blow or vacuum dust from all sanding parts and motor housing.

WARNING: Any attempt to repair or replace electrical parts on this tool may be

hazardous. Repairs should be done by a qualified service technician.

LUBRICATION

Ball bearings are grease packed at the factory and require no further lubrication.

Use a spray lubricant on all moving table parts to ensure smooth operation.

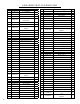

ADJUST THE DRIVE BELT

1. Loosen the screw (1) securing the drive belt housing cover to the drive belt hous-

ing. Lift the cover up and over the screw and remove it.

2. Using a Phillips screwdriver (not included), loosen the 3 screws (2) securing the

drive belt housing to the sander body.

3. Using the included hex wrench, loosen (turn counterclockwise) the hex screw (3)

at the bottom of the drive belt housing. This will release the tension on the drive

belt and allow you to perform adjustments or install a new drive belt.

4. Re-seat the belt on the pulleys, making sure the belt is properly seated in the

grooves of both pulleys.

5. Re-tighten the belt by tightening (turning clockwise) the hex screw at the bottom

of the drive belt housing.

6. Tighten all 3 screws (2).

(continued on next page)