Built-In Ceramic Hotplate Operation Manual Model HC-1006, HC-1256, HC-2256

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

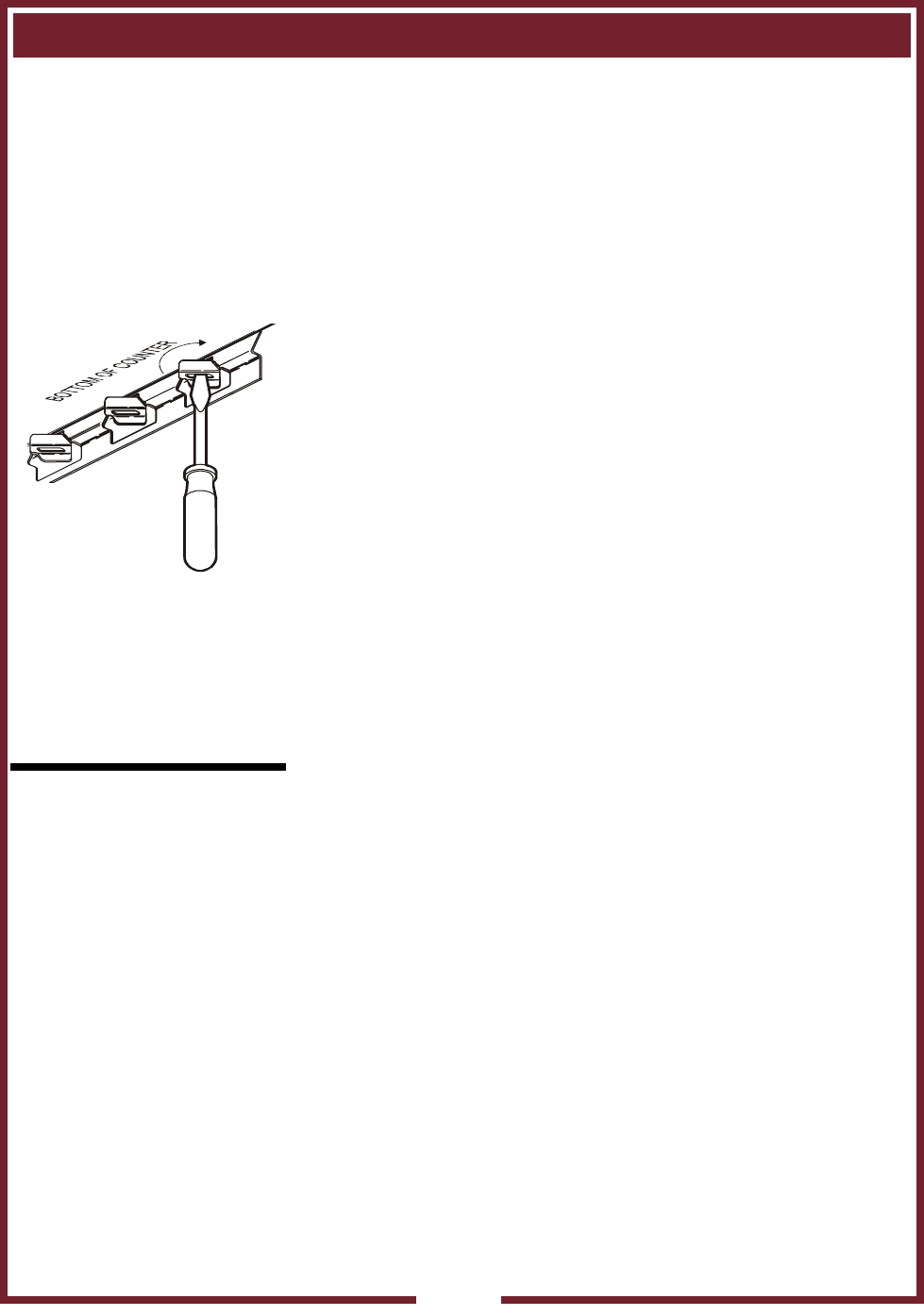

Fig. 3 Set the Wellsloks

IMPORTANT:

Water damage caused by

failure to seat Wellsloks or

failure to install gasket or to

seal flange to counter is NOT

covered by warranty

IMPORTANT:

Contact a licensed electrician

to install and connect electrical

power to the hotplate.

IMPORTANT:

Damage due to being

connected to the wrong voltage

or phase is NOT covered by

warranty.

UNPACKING & INSPECTION

Carefully remove the hotplate from the carton. Remove all

protective plastic film, packing materials and accessories from the

hotplate before connecting the hotplate into electrical power or other-

wise performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the hotplate before starting any

installation.

Read and understand all labels and diagrams attached to the

hotplate.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient

place for later use.

PREPARATION

Carefully read the Installation Instruction Sheet packed with the

hotplate for cutout dimensions and restrictions.

For wood and non combustible (i.e. metal) installation, do not install

closer than 1 inch to back and side walls, 3-5/8" between unit

Supplied gasket must be installed under the mounting flange, and the

Wellsloks turned out to seal the hotplate and control unit to the

counter.

Apply a thin bead of food-grade silicone sealant where the flange

meets the counter.

ELECTRICAL

Hotplate must be installed by a licensed electrician in accordance with

all applicable codes and ordinances.

Refer to the nameplate. Verify the electrical service power. Voltage

and phase must match the nameplate specifications. Connecting the

hotplate to the wrong voltage can severely damage the equipment or

cause noticeably decreased performance.

For supply connections, use 14 ga. (HC-1006) or 10 ga. (HC-1256

and HC-2256) copper wires suitable for at least 75ºC.

The ground lug of the hotplate and control unit must be connected to

a suitable building ground.

4