User Documentation

Table Of Contents

- Content

- 1 About this documentation

- 2 Safety

- 3 IO-Link overview

- 4 Module description

- 5 Assembly and installation

- 6 Commissioning

- 6.1 Requirements

- 6.2 Device description files

- 6.3 Procedure for commissioning

- 6.4 Commissioning with the SIMATIC Manager (PROFINET)

- 6.5 Commissioning with the TIA portal(PROFINET)

- 6.6 Commissioning with TwinCAT (EtherCAT)

- 6.7 Commissioning with Studio 5000(Ethernet/IP)

- 6.8 Commissioning with Automation Studio (POWERLINK)

- 6.9 Reading and writing data objects on IO-Link devices

- 6.10 “IO_LINK_CALL” function block

- 6.11 I&M functions

- 7 Planning IO-Link device configurations

- 8 Process data

- 9 Diagnostics and troubleshooting

- 10 Disassembly and disposal

6 Commissioning | “IO_LINK_CALL” function block

39Manual Communication module UR20-4COM-IO-LINK2547720000/03/09.2019

IO_LINK_CALL:outputparameters

Parameter Data type Description

DONE_VALID BOOL

Validity of data

0: Data invalid

1: Data valid

BUSY BOOL Read access / write access is executed

ERROR BOOL

0: no error

1: error and cancellation

STATUS DWORD Communication error message

IOL_STATUS DWORD IO-Link error message

RD_LEN DWORD Length of the data read

Processing of the function block lasts several PLC cycles.

The access, use of IO-Link port functions and the remaining

backup and recovery of device data must be controlled by

the user program.

SIEMENS offers the STEP7 IO-Link library for SIMATIC Man-

ager and the TIA Portal. In the more recent versions of the

IO-Link library, “IO_LINK_CALL” has been replaced by the

“IO_LINK_DEVICE” block.

Further information is available in the SIEMENS

document “Acyclic reading and writing with the

IO-Link library”.

You can download the SIEMENS IO-Link library

from the SIEMENS support website.

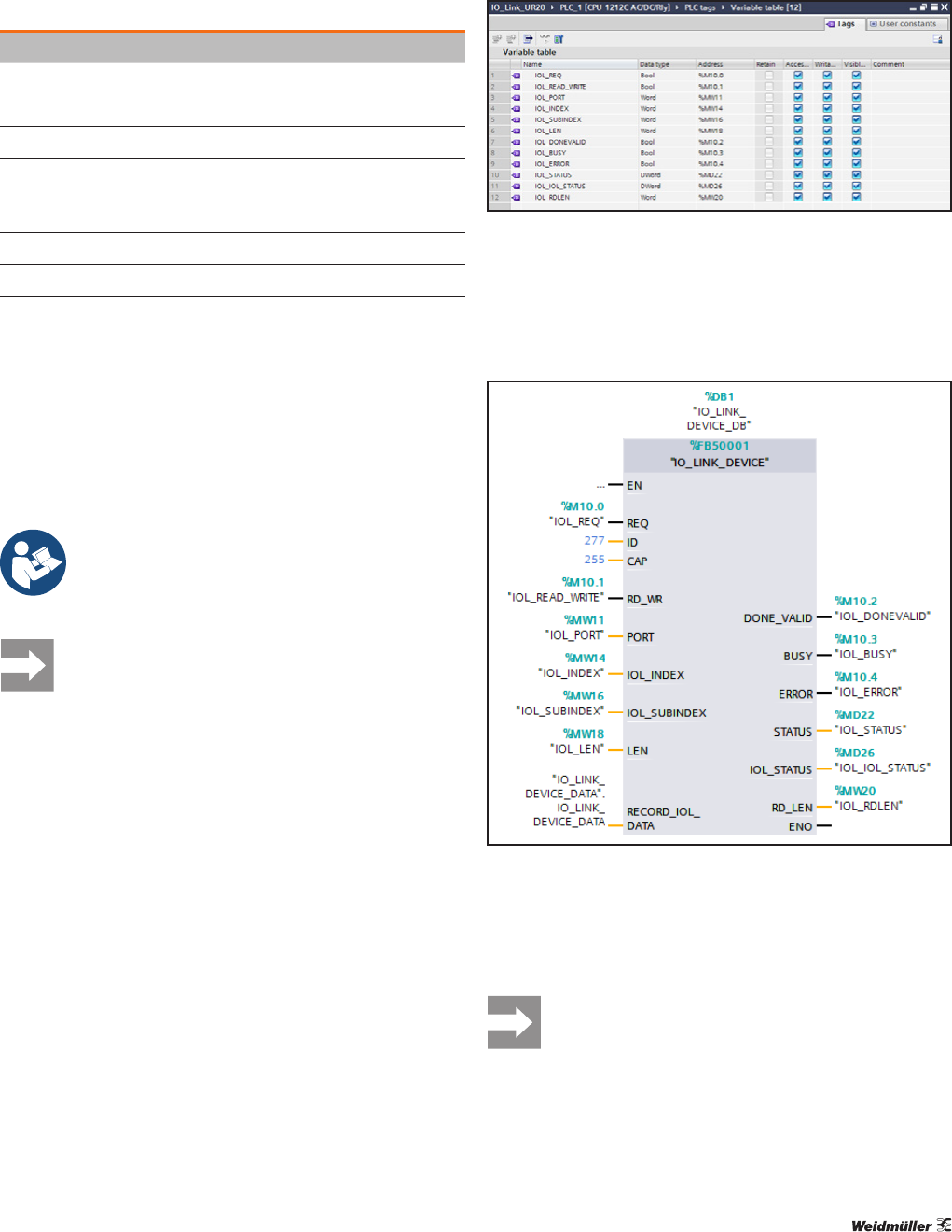

Reading and writing with “IO_LINK_DEVICE” in STEP7

You can read and write IO-Link device parameters using the

“IO_LINK_DEVICE” function block.

▶ Add the “IO_LINK_DEVICE” function block to the OB1 of

your user program.

▶ Create a new data block of type

ARRAY[0...231]ofBYTE.

This data block is the target range for data read and the

source range for data to be written.

▶ Generate a new variable table for the input parameters

and output parameters of the function block.

Variable table for “IO_LINK_DEVICE” (TIA portal)

▶ Assign the variables to the inputs and outputs of the

function block.

You can enter the parameters ID and CAP directly on the

function block.

“IO_LINK_DEVICE” function block (TIA portal)

▶ Create a watch and force table with the input parameters

and output parameters of the function block.

▶ Force the variables for the input parameters to the

required values.

In the case of S7-300/400 CPUs, use the logical

start address of the module inputs as ID.

In the case of S7-1200/1500 CPUs, use the hard-

ware address of the module as ID.