Technical data

BBW 46 / DBW 46

9 Repair

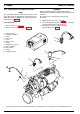

905

9.2.2.2 Installation

1. Apply Copaslip (Ident. No. 105898) to thread of

temperature limiter (2, Fig. 902) and manually screw

into heat exchanger (9).

2. Using a fork wrench tighten temperature limiter (2)

with a third of a turn. Maximum torque 1.5 Nm.

3. Fit protective cap (1).

4. Make electrical connections (see 9.2.1.2).

5. Install heater (see 8.7.1.2).

9.2.3 Replacement of Temperature Fuse

9.2.3.1 Removal

1. Remove heater (see 8.7.1.1).

2. Break electrical connections (see 9.2.1.1).

WARNING

When removing temperature fuse from installed condition

allow coolant to cool down sufficiently to prevent skin

burns.

Also depressurise cooling system and refit cap

afterwards.

3. Unscrew temperature fuse (12, Fig. 902) from heat

exchanger (9) and remove together with O-ring (11).

4. Perform procedures on components after

disassembly (refer to 9.1.1).

9.2.3.2 Installation

1. Apply Copaslip (Ident. No. 105898) to thread of

temperature fuse (12, Fig. 902).

2. Manually screw temperature fuse (12) with O-ring (11)

into heat exchanger (9).

3. Ensure temperature fuse is screwed properly into heat

exchanger. Distance between surfaces to be approx.

0.8 mm.

4. Make electrical connections (see 9.2.1.2).

5. Install heater (see 8.7.1.2).

9.2.4 Replacement of Temperature Sensor

9.2.4.1 Removal

1. Remove heater (see 8.7.1.1).

2. Break electrical connections (see 9.2.1.1).

WARNING

When removing temperature sensor from installed

condition allow coolant to cool down sufficiently to prevent

skin burns.

Also depressurise cooling system and refit cap

afterwards.

3. Unscrew temperature sensor (8, Fig. 902) and

remove together with O-ring (7).

4. Perform procedures on components after

disassembly (refer to 9.1.1).

9.2.4.2 Installation

1. Apply Copaslip (Ident. No. 105898) to temperature

sensor (8, Fig. 902), manually screw with O-ring (7) in

place into heat exchanger (9) and tighten with 0.5 Nm.

2. Make electrical connections (see 9.2.1.2).

3. Install heater (see 8.7.1.2).

9.2.5 Replacement of Flame Sensor

9.2.5.1 Removal

1. Remove heater (see 8.7.1.1).

2. Break electrical connections (see 9.2.1.1).

3. Loosen lock screw (4, Fig. 902).

4. Withdraw flame sensor (6) on clamp together with O-

ring (5).

5. Perform procedures on components after

disassembly (refer to 9.1.1).

9.2.5.2 Installation

1. Apply non-acid grease to O-ring (5, Fig. 902) and

locate on flame sensor (vent port must remain open).

2. Slide flame sensor (6) into burner head (10).

3. Apply copper paste to lock screw (4) and screw into

burner head (10).

4. Make electrical connections (see 9.2.1.2).

5. Install heater (see 8.7.1.2).

9.2.6 Replacement of Circulation Pump

NOTE

For a circulation pump mounted externally in vehicle the

following procedure is similar.

WARNING

When removing circulation pump from installed condition

allow coolant to cool down sufficiently to prevent skin

burns.

Also depressurise cooling system and refit cap

afterwards.