User guide

APPENDIX 103

3 Strip each of the seven SmartSensor cable wires back about 1/4 in. (0.6 cm).

4 Insert the wires into the contacts and verify the wire is visible through the contact

inspection hole.

5 Crimp the wires by following the crimping tool instructions. Daniels Manufacturing

Company provides professional grade crimping tools and detailed instructions on

crimping. Wavetronix recommends the DMF AF8 M22520/1-01 or equivalent tool for

crimping.

6 Manually press the contacts into the back side of the connector plug.

7 Use a DMC DAK20 (or equivalent) insertion tool to fully seat the contact into the con-

nector plug. Check the mating face of the connector to ensure that all the contacts are

fully inserted. A DMC DRK20 extractions tool (or equivalent) is necessary to remove

a misplaced or misaligned contact.

8 read the back shell onto the connector plug. To keep the connector from rotating

during the threading process, connect the plug and coupling ring to a sensor connec-

tor receptacle.

9 Press all of the connector parts together. read the strain relief onto the back shell.

10 Tighten the strain relief screws on the back.

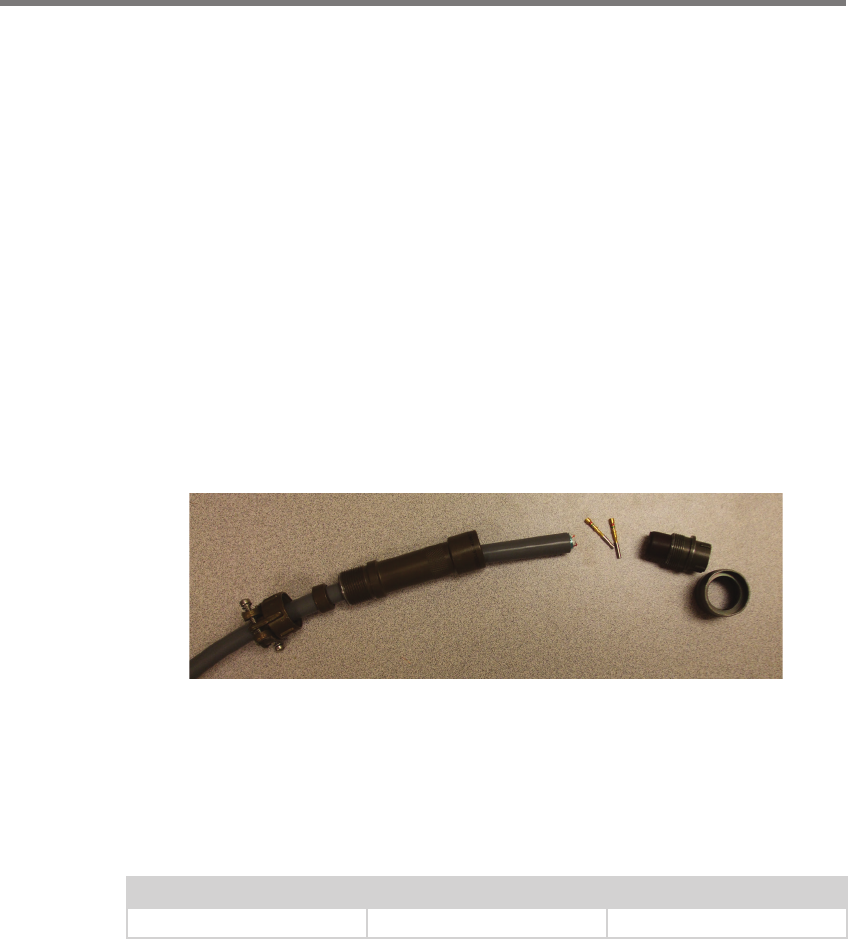

Figure A.2 – Connector Sub-assembly Parts

Appendix B – Cable Lengths

It is recommended that the sensor be powered by 24 VDC to achieve reliable operation up

to 500 . (152.4 m) away. Table B.1 lists maximum cable lengths for 12 and 24 VDC.

Power Wire Gauge 24 Volts 12 Volts

20 AWG 500 ft. (152.4 m) 90 ft. (27.4 m)

Table B.1 – Maximum Cable Length for Power (ft)

For communications, both of the sensor’s RS-485 communication ports operate at 9600

bps.