Operator`s manual

Table Of Contents

- 1 Foreword

- 2. Safety Information

- 2.1 Operating Safety

- 2.2 Service Safety

- 2.3 Operator Safety while using Internal Combustion Engines

- 2.4 Towing Safety

- 2.5 Reporting Trailer Safety Defects

- 2.6 Label Location

- 2.7 Safety and Operating Labels

- 3. Operation

- 3.1 Control Panels

- 3.2 Generator Monitoring

- 3.3 Engine Monitoring

- 3.4 Engine Shutdown Faults

- 3.5 Current Overload Fault

- 3.6 Application

- 3.7 Voltage Selector Switch

- 3.8 Emergency Stop Switch

- 3.9 Main Line Circuit Breaker

- 3.10 Engine Start Switch

- 3.11 Voltage Adjustment Rheostat

- 3.12 Warning Light

- 3.13 Connection Lugs

- 3.14 Ground Connection

- 3.15 Convenience Receptacles

- 3.16 Remote Run Terminal Block

- 3.17 Panel Door Interlock Switch

- 3.18 Terminal Connections

- 3.19 Before Starting

- 3.20 Manual Start-up

- 3.21 Running the Generator

- 3.22 Engine Power Correction Factors

- 3.23 Shutting Down Generator

- 3.24 Cold Weather Start-up

- 3.25 Lifting

- 3.26 Overnight Storage

- 3.27 Long-term Storage

- 3.28 Automatic/Remote Start-up

- 3.29 Remote/Transfer Switch

- 3.30 Towing

- 4. Maintenance

- 4.1 Periodic Maintenance Schedule

- 4.2 New Machines

- 4.3 Resetting the Periodic Maintenance Timer

- 4.4 Air Cleaner

- 4.5 Engine Lubrication

- 4.6 Engine Coolant

- 4.7 Trailer Maintenance

- 4.8 Troubleshooting Automatic Shutdown

- 4.9 Wire Colors

- 4.10 Generator and Receptacle Wiring

- 4.11 Trailer Wiring

- 4.12 G 50/G 70 Engine Wiring

- 4.13 G 85 & G 70 w/ECU Engine Wiring

- 5 Factory-Installed Options

- 5.1 Block Heater

- 5.2 Fuel/Water Separator

- 5.3 Electronic Governor

- 5.4 LCD Strip Heater

- 5.5 Low Coolant Shutdown

- 5.6 Lube Level Maintainer

- 5.7 Temperature-Activated Shutters

- 5.8 Lockable Battery Disconnect

- 5.9 Wiring Diagram

- 5.10 Wiring Diagram Components

- 5.11 Cam-Lock

- 5.12 Containment System

- 6. Technical Data

- 6.1 Engine Data

- 6.2 Generator Data

- 6.3 Trailer and Skid Data

- 6.4 Dimensions

Factory-Installed Options Mobile Generators

wc_tx000380gb.fm 78

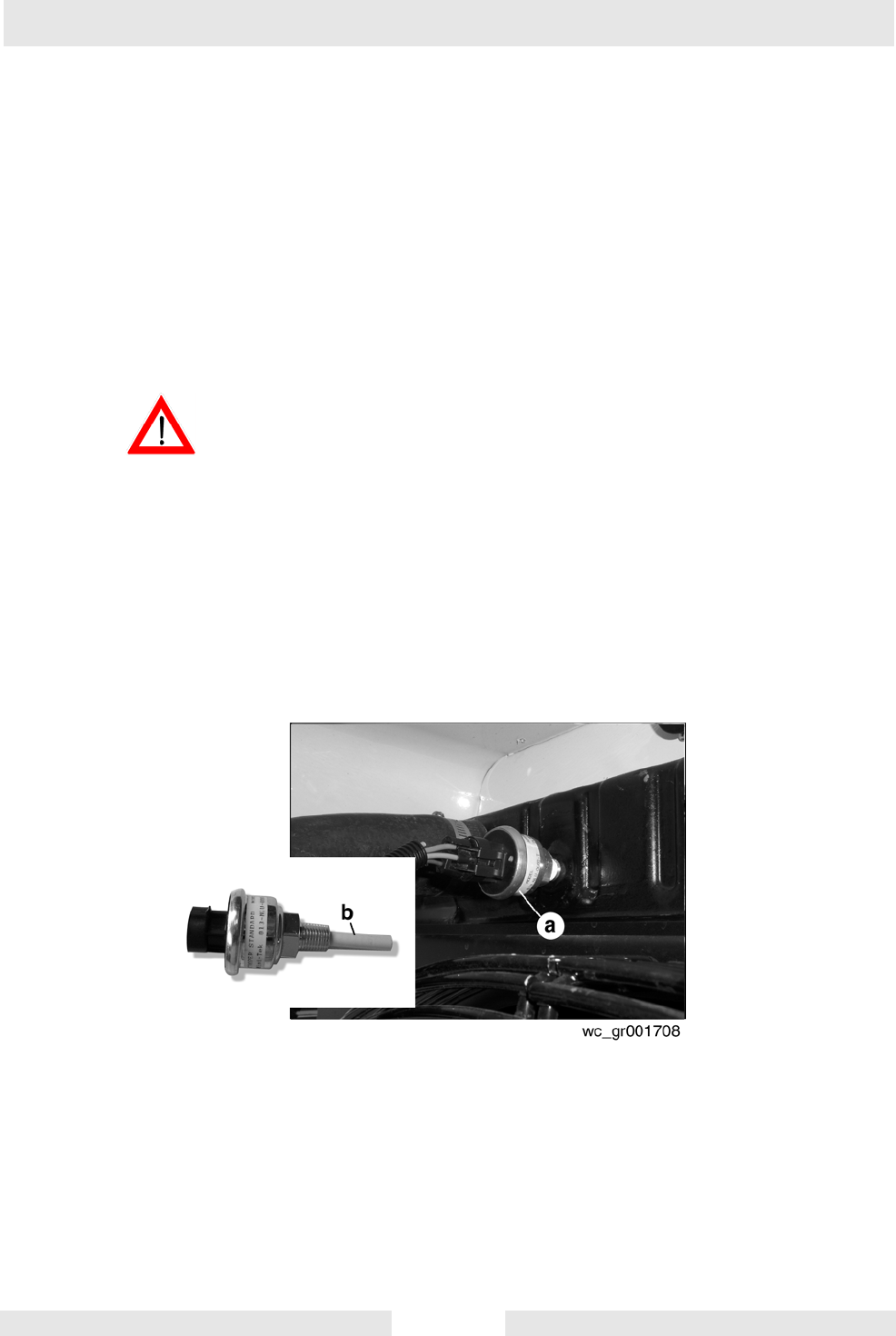

5.5 Low Coolant Shutdown

See Graphic: wc_gr001708

The low-coolant shutdown system consists of an electronic sensor that

monitors coolant level. The sensor (a) is mounted to the radiator and

wired into the ECM. The sensor probe (b) is submerged in radiator

coolant. If the probe senses no coolant, it sends a signal to the ECM.

The ECM program includes a 10-second timer to protect from

nuisance shutdowns. If after the ten seconds coolant levels are still

sensed as being low, the ECM shuts down the engine. The ECM will

then display the “FAULT LOW WATER LEVEL”. Allow the engine to

cool before adding additional coolant.

NEVER remove the radiator cap while the engine is hot! Pressurized

coolant can cause serious burns.

If it is necessary to open the radiator, only do so with the engine off,

and only when coolant is cool enough to touch with bare hands. Slowly

loosen the radiator cap to relieve pressure first, before removing it

completely.

Note: The sensor may be disabled by unplugging the wire harness.

This action will not shut down the machine.

WARNING