Specifications

– 16 –

SCALE RELATED MAINTENANCE

Periodic maintenance is necessary to keep your boiler clean and efficient. Initially, after three months

of steamer usage, it is recommended that you have your Vulcan-Hart authorized servicer inspect the

boiler and perform the descaler maintenance described below. Local water conditions and steamer

usage will determine the frequency that this service must be repeated; however, a minimum

recommendation is once a year. This maintenance is not covered by warranty.

Cathodic protector(s) are provided inside the boiler to reduce boiler corrosion and help keep zinc and

other metallic complexes in suspence, preventing hard scale from forming on the boiler interior. The

cathodic protector(s) will be consumed. How fast the cathodic protector(s) will be consumed depends

upon the chemical makeup of the feed water and the average volume of feed water used. An inspection

by service personnel is recommended so that the expected normal life of the cathodic protector(s) can

be estimated under your operating conditions. Thereafter, the cathodic protector(s) can be serviced

at the appropriate frequency for your situation.

LUBRICATION

The door screw was factory lubricated with high-temperature grease, but will require periodic

relubrication. When the door screw is properly lubricated, the hand pressure required to seal the door

is greatly reduced and the life of the screw and nut are lengthened. The frequency of lubrication should

depend upon use. Lubricate monthly at first and let experience determine the frequency. A high-

temperature door screw grease can be obtained from Vulcan-Hart Company.

FORM 35409 (May 2003) PRINTED IN U.S.A.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this steamer, contact the Vulcan-Hart Service

Agency in your area (refer to listing supplied with the steamer), or contact the Vulcan-Hart Company

Service Department at the address or phone number shown on the front cover of this manual.

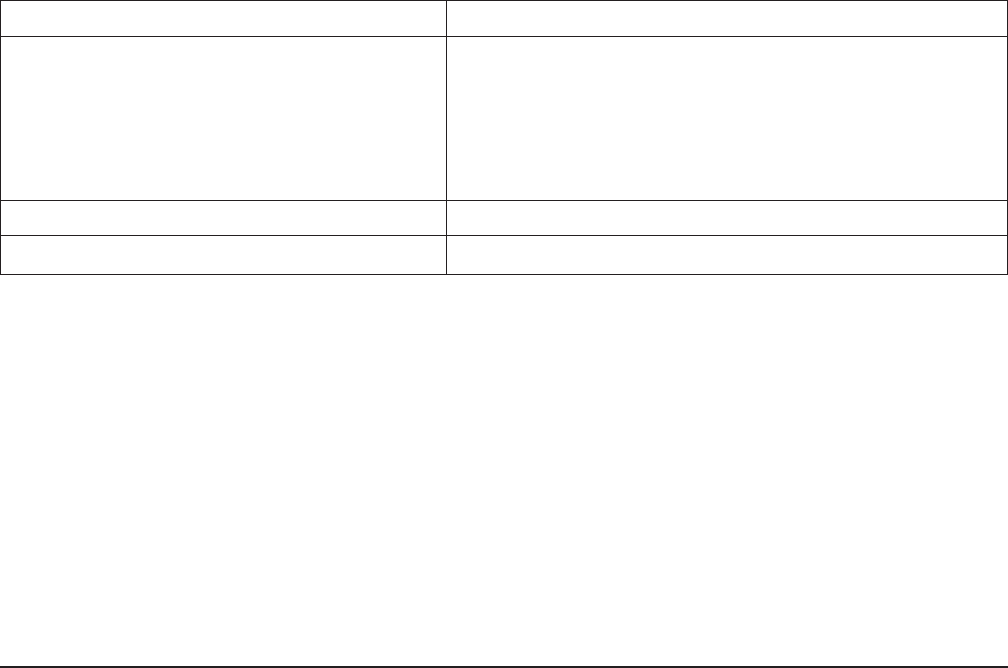

Symptoms Possible Causes

Steamer will not heat or build pressure. 1. Water supply to steamer is not turned on.

2. Water filter may be clogged.

3. Main gas supply valve may be turned off.

4. Electrical supply may be off or disconnected.

5. Combination gas valve may be turned off.

6. Ignition switch may be turned off.

Water accumulates in compartment. Drain may be clogged. Clear drain.

Other problems. Contact Service.

TROUBLESHOOTING