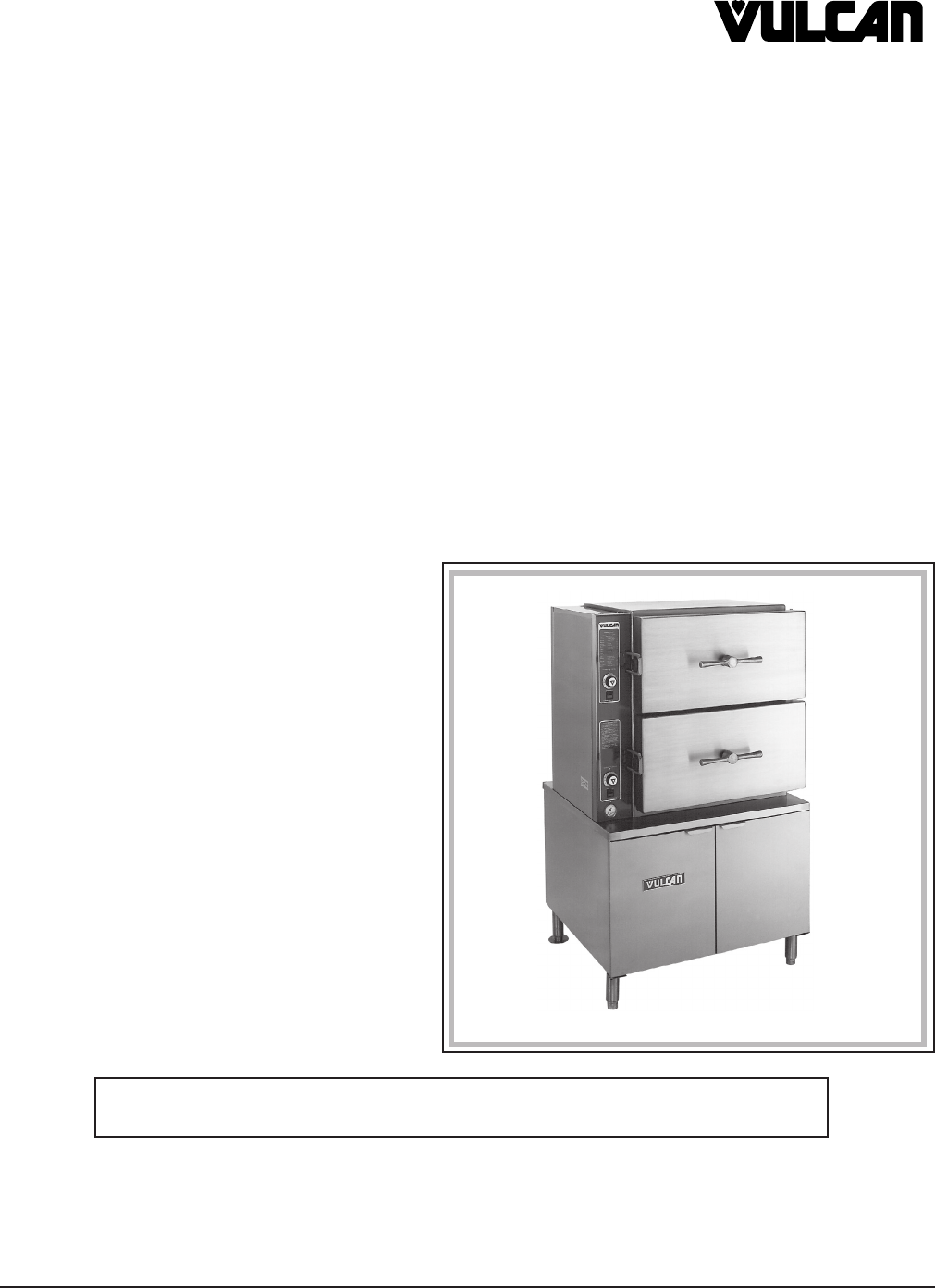

INSTALLATION & OPERATION MANUAL VL2GSS & VL3GSS GAS FOOD STEAMERS MODEL VL2GSS VL3GSS ML-52389 ML-52393 Model VL2GSS For additional information on Vulcan-Hart Company or to locate an authorized parts and service provider in your area, visit our website at www.vulcanhart.com VULCAN-HART COMPANY, FORM 35409 (May 2003) P.O. BOX 696, LOUISVILLE, KY 40201-0696, TEL. (502) 7 7 8 - 2 7 9 1 www.vulcanhart.

IMPORTANT FOR YOUR SAFETY THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL. POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS SUPPLIER.

TABLE OF CONTENTS GENERAL ......................................................... 4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Remove the Burner Shipping Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation, Operation and Care of VL2 & VL3 GAS FOOD STEAMERS SAVE THESE INSTRUCTIONS GENERAL Vulcan-Hart suggests that you thoroughly read this entire manual and carefully follow all of the instructions provided. Your Vulcan Model VL Food Steamer is produced with quality workmanship and materials. Its boiler is fully automatic with the heat input controlled by preset pressure switches. A solenoid valve feeds makeup water as needed. The steamer is equipped with adjustable feet.

INSTALLATION CODES AND STANDARDS In the United States, the Vulcan steamer must be installed in accordance with state and local codes, with the National Fuel Gas Code, (ANSI-Z223.1, latest edition) available from the American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209, with the National Electrical Code (ANSI/ NFPA No.

PLUMBING CONNECTIONS WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY AND PLUMBING CODES. Water Supply Connections The water filter, provided, must be installed in the water supply line going to the filtered water inlet or your steamer warranty may be voided. For incoming water supply line pressures, refer to the water filter manual shipped with the water filter. Follow the recommendations contained in it. Unfiltered water should be connected to the condenser on the blow-down line.

GAS CONNECTION CAUTION: All gas supply connections and any pipe joint compound used must be resistant to the action of liquefied petroleum gases. Codes require that a gas shutoff valve be installed in the gas line ahead of the steamer. Connect the gas supply line to the gas valve on the steamer. Make sure the pipes are clean and free of obstructions, dirt and piping compound. The gas line must be capable of delivering gas to the steamer without excessive pressure drop at the rate specified on the nameplate.

INSTALLATION DRAWING LEGEND GAS CONNECTION: 3/4" NPT Models VL2GSS & VL3GSS BOILER FEED CONNECTION FOR FILTERED WATER: 1/4" NPT WATER CONNECTION FOR BOILER DRAIN CONDENSER: 1/ 4" NPT ELECTRICAL CONNECTION: 120 V, 60 HZ, 1 PH, 300 WATTS MAX DRAIN: 3 1/2" DIA. PROVIDE FLOOR SINK FOR OPEN GAP TYPE DRAIN. DO NOT PLACE FLOOR SINK DIRECTLY UNDER STEAMER. DO NOT CONNECT SOLIDLY TO ANY DRAIN CONNECTION. NOTE: DIMENSIONS WHICH LOCATE THE ABOVE CONNECTIONS HAVE A TOLERANCE OF + OR - 3 IN. (75 MM).

DRAIN REQUIREMENTS The floor sink is not to be located under the steamer. Fig.

OPERATION WARNING: THE STEAMER AND ITS PARTS ARE HOT. CLEANING AND SERVICING THE STEAMER. USE CARE WHEN OPERATING, STEAMERS WITH ELECTRONIC IGNITION 1. Make sure all supply connections for electric, gas and water are on. 2. Turn the knob on the Gas Combination Valve (Fig. 7) counterclockwise to the ON position. 3. If equipped with the Manual Blow Down Valve (Fig. 7), make sure it is closed. 4. Keep both valves (one each at the top and bottom) of the gauge glass open at all times. 5.

OPTIONAL MANUAL BLOW DOWN VALVE AUTOMATIC BLOW DOWN VALVE GAS COMBINATION VALVE Fig.

STEAM COOKING — COMPARTMENT OPERATION Refer to the Steam Cooking with Vulcan Kettles and Steamers (booklet packed with your steamer) for suggested cooking times of various foods. All cooking times are approximate because size, weight, pan loading and product quality will affect steamer cooking times. Use these suggestions and then adjust cooking times to your own requirements. 1.

SELECTION OF PANS FOR STEAM COOKING VL steamer compartments are designed to accept combinations of the following perforated or solid cooking pans (Fig. 8): PAN ACCOMODATION, PER COMPARTMENT Max Qty Pan Size Pan Depth 4 12 X 20 6 6 12 X 20 4 8 12 X 20 2 1/ 2 6 18 X 26 16 (center support removed) 1 12 x 20 1 Fig.

FROZEN PRODUCT Perforated Frozen Vegetables. Loosen and spread vegetable. Broccoli, asparagus spears, green beans, carrots, brussel sprouts, turnips, potatoes, cut corn, lima beans, peas, squash. Solid Precooked Dishes. Remove wrapping and place in pan. All precooked dishes, such as beef goulash, chicken fricasse, etc., which cannot be cooked in the containers in which they are packed. Separate frozen food packs into smaller chunks.

DOOR GASKETS Clean the gasket sealing surface of the compartment doors to remove harmful food acids for maximum gasket life. Do not use any solvents. Wash with a cloth moistened in a solution of mild detergent and warm water. Rinse with a fresh cloth moistened with warm water to remove all traces of detergent. Wipe dry with a clean cloth. Never apply food oils or petroleum lubricants directly to the door gasket. Petroleum-based solvents and lubricants will shorten gasket life.

SCALE RELATED MAINTENANCE Periodic maintenance is necessary to keep your boiler clean and efficient. Initially, after three months of steamer usage, it is recommended that you have your Vulcan-Hart authorized servicer inspect the boiler and perform the descaler maintenance described below. Local water conditions and steamer usage will determine the frequency that this service must be repeated; however, a minimum recommendation is once a year. This maintenance is not covered by warranty.