user manual

Table Of Contents

- FOREWORD

- TABLE OF CONTENTS

- TOOL AND SUPPLY REQUIREMENTS

- PARTS LIST (Universal Small...

- PARTS LIST (Universal Small...

- PARTS LIST (Universal Small...

- 1. PREPARATION/REMOVAL

- 2. OIL FEED INSTALLATION

- 3. OIL DRAIN INSTALLATION

- 4.1 MAIN BRACKET/SUPERCHARGE...

- 4.2 MAIN BRACKET/SUPERCHARGE...

- 5. CRANK PULLEY AND SUPERCHA...

- 7. FINAL REASSEMBLY AND CHECK

- 6. DISCHARGE DUCTING/CARBURE...

- 7. FINAL REASSEMBLY AND CHECK

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

2

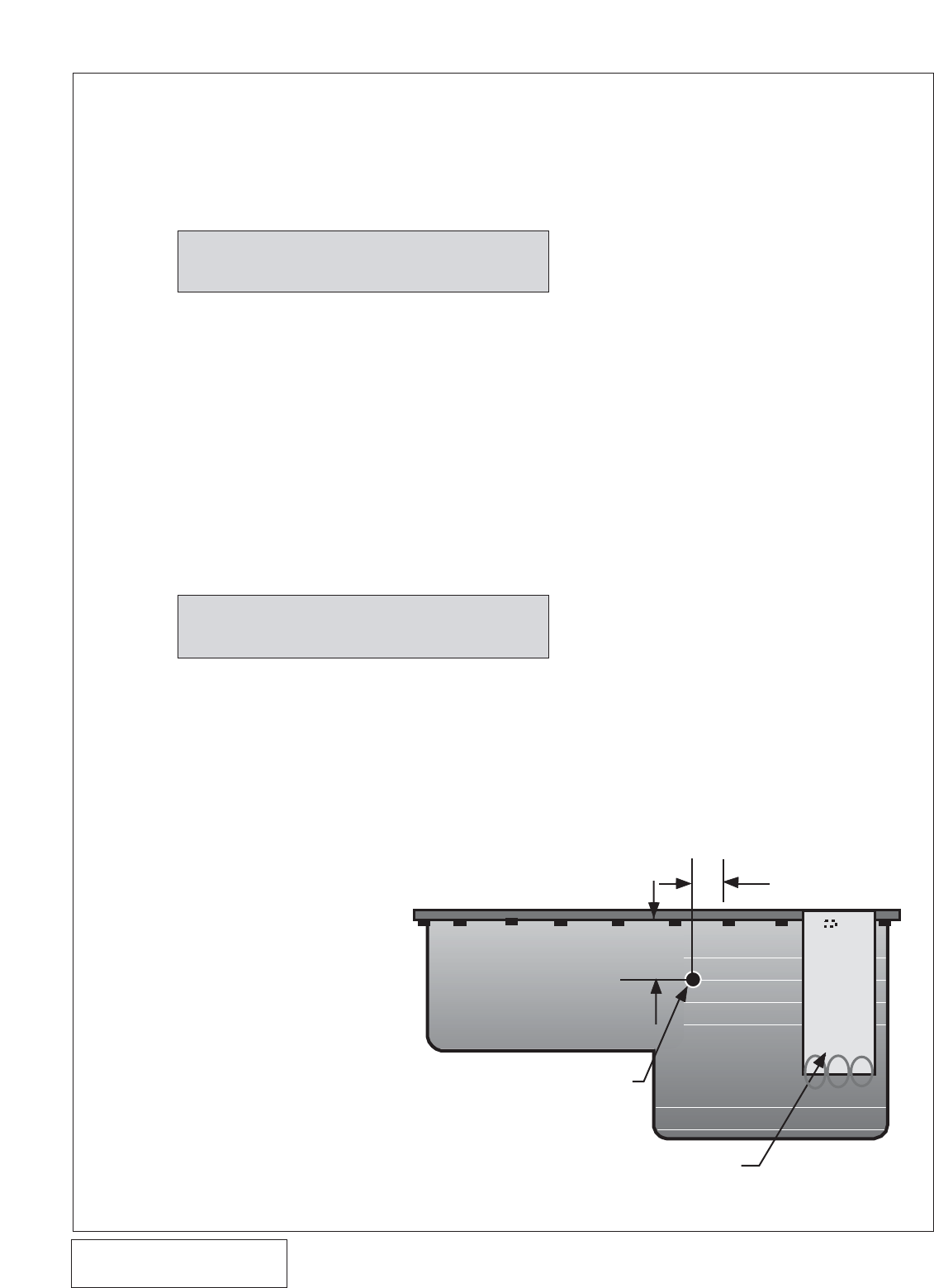

Fig. 3-a

3. OIL DRAIN INSTALLATION

IN-LINE

FOURTH BOLT

OIL PAN

OIL FILTER

PUNCH HOLE THROUGH

DOWN 2"

1"

A. To provide an oil drain for the supercharger, it

is necessary to make a hole in the oil pan.

Locate and mark the hole location. (See Fig.

3-a.) It is best to punch the hole rather than

drill.

B. Remove any paint from around the hole area.

C. Use a small center punch to perforate the

pan and expand the hole, switch to a larger

diameter punch and expand the hole further

to approximately Ø9/16". Most punches are

made from hexagon material and may be

placed in a socket with an extension to make

this procedure easier. Use caution so that the

hole is not enlarged too much and that the

punch does NOT contact the crankshaft.

D. Tap the hole with a 3/8"NPT tap approximate-

ly 1/4" deep. Pack the flutes of the tap with

heavy grease to hold the chips. Use a small

magnet to check for any stray chips.

E. Thoroughly clean the threaded area. Apply a

small amount of silicone sealer to the new

threads. Apply more sealer to the supplied

3/8"NPT x 90° elbow and secure in the previ-

ously threaded hole. Make sure a seal is

formed all around the fitting. Rotate the fitting

so that the oil drain hose can be easily routed

to it. Apply sealer to the supplied 3/8"NPT x

1/2" beaded hose barb fitting and install in

the previously installed 90° elbow.

F. Drain the engine oil, install a new filter and

refill with fresh oil.

NOTE: Removal of the oil pan may ease oil

drain fitting installation on some applica-

tions.

NOTE: This method of rolling over the lip of the

hole and tapping works well if carefully

done and should cause no problems.