Datasheet

BFC2 808 .....

www.vishay.com

Vishay BCcomponents

Revision: 04-Aug-15

4

Document Number: 28527

For technical questions, contact: dc-film@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

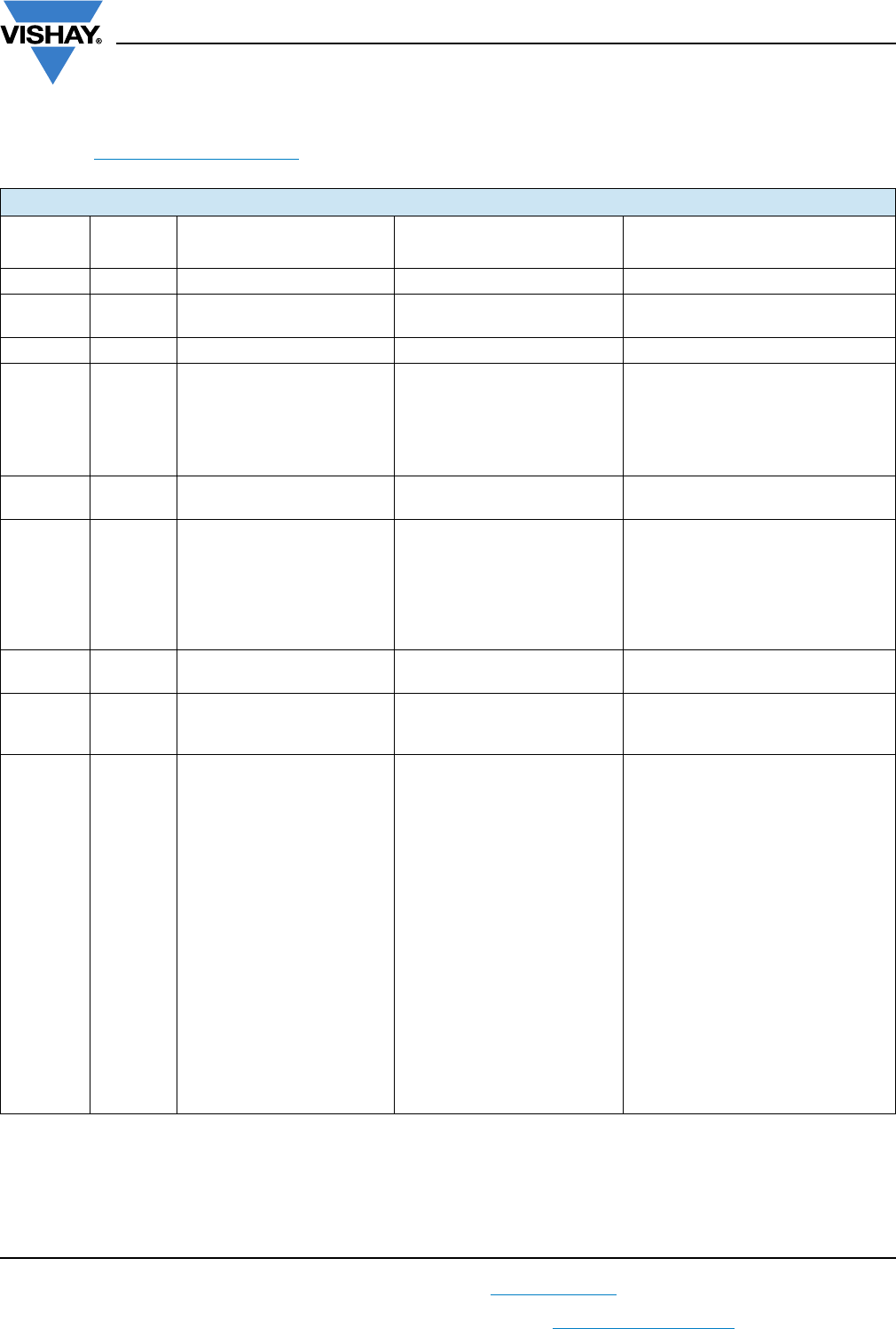

SOLDERING CONDITIONS

For general soldering conditions and wave soldering profile, we refer to the application note “Soldering Guidelines for Film

Capacitors”: www.vishay.com/doc?28171

TEST PROCEDURES AND REQUIREMENTS

IEC

60418-1

CLAUSE

IEC 60068

TEST

METHOD

TEST PROCEDURE REQUIREMENTS

4.2 Method of mounting Method A

14 Capacitance drift After TC measurement C/C: 1 % for C

max.

< 40pF;

C/C: 2.5 % for C

max.

40pF

19 Thrust Axial thrust of 2N C/C: 0.3 %

21 Robustness of terminations:

21.1 Ua Tensile 1N No damage

21.2 Ub Bending 1 cycle No damage

22 Na Rapid change of temperature 1 cycle; 0.5 h at lower and 0.5 h

at upper category temperature

C/C: 2 %

23 T Soldering:

Ta Solderability Solder bath immersion 3mm;

235°C;2s

Good wetting,

no mechanical damage

Tb Resistance to heat Solder bath: 260°C;10s No mechanical damage

24 Eb Impact bump 4000 ± 10bumps; 40g;6ms C/C: 0.6 %;

no mechanical damage

25 Fc Vibration Frequency 10Hz to55Hz;

amplitude 0.35mm;

1.5 h

C/C: 0.6 %;

no mechanical damage

26 Climatic sequence: C/C: 4 %

26.1 B Dry heat 16h at upper category

temperature

tan : 10 x 10

-4

for C

max.

< 27pF;

tan : 70 x 10

-4

for C

max.

27pF;

tan : 80 x 10

-4

for C

max.

40pF

R

ins.

: 10 000M;

rotor contact R: 10m

26.2 D Damp heat accelerated,

first cycle

1 cycle; 24 h; +40 °C;

95% to100 % RH

Voltage proof:

500V for 1min

26.3 Aa Cold 16h; -40 °C Visual examination:

no mechanical damage

26.5 Damp heat accelerated,

remaining cycles

1 cycle; 24 h; +40 °C;

95 % to 100 % RH

Operating torque:

1mNm to15mNm for C

max.

< 33pF;

1mNm to25mNm for C

max.

33pF