Operating instructions

Supporting DIRECT-TEMP: Vertical Support

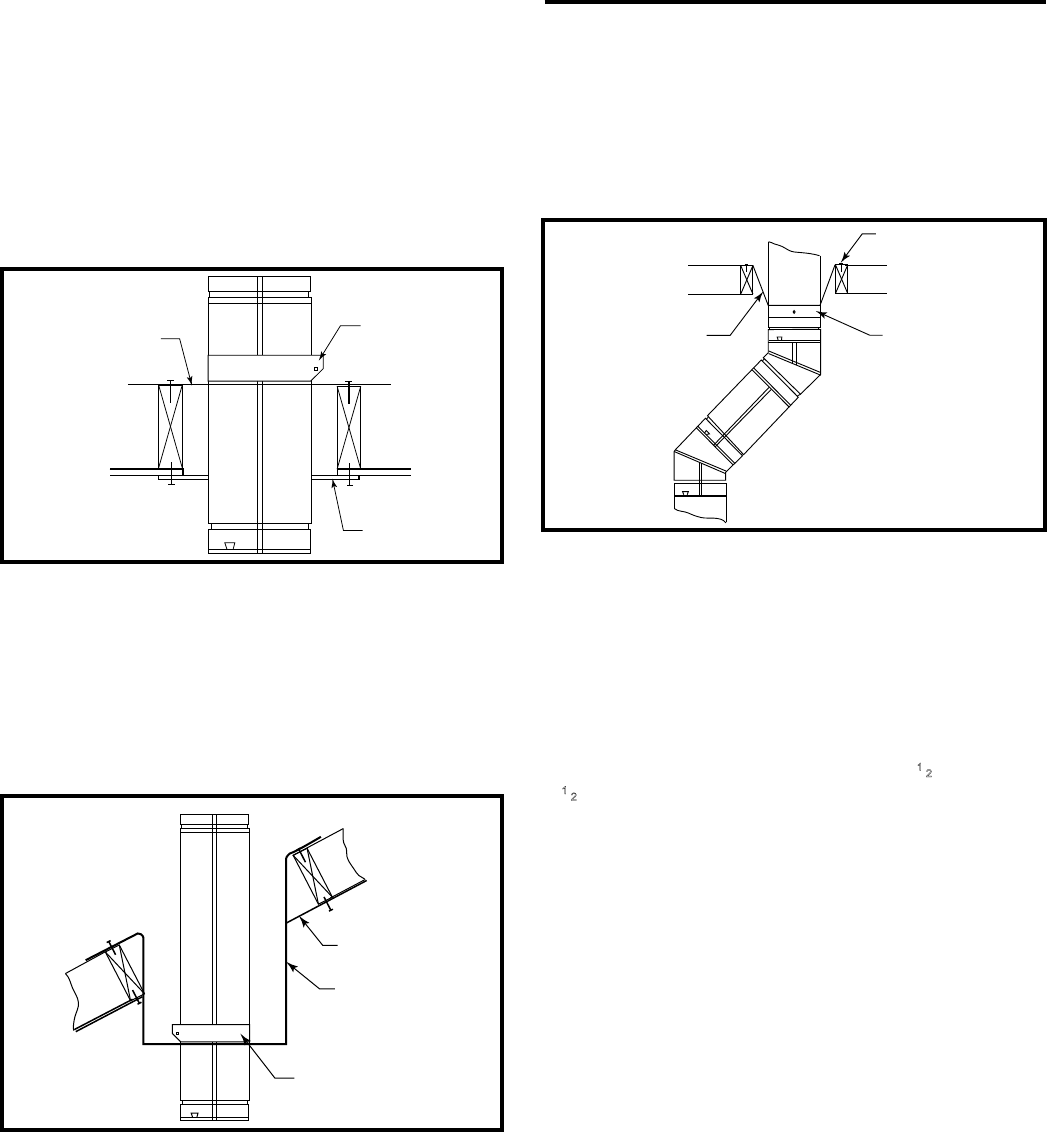

Vertical installations can be supported by two methods:

Ceiling Support (CS) (used in at ceiling installation) comes

with a support plate and a support collar. Install it by screw-

ing the support plate to the top of the properly framed ceil-

ing joist opening, using screws provided. A round trim plate

(TP) is attached to the ceiling, using screws, to provide a

nished appearance once installed. (Figure 35)

The Cathedral Ceiling Support (CCS) may be used in

ST923

Selkirk

vertical support

6/07

Ceiling Support

Plate

Ceiling Support

Collar

Trim Plate

ST923

Figure 35 Ceiling support.

pitched or at ceiling installations and comes with a sup-

port collar and a decorative two part square trim plate. In-

stall by inserting the support box down through the framed

joist opening (end with round hole rst) in the ceiling using

tin snips, cut the corners of the open end of the box such

that the sides can be folded down over the top of the joist

framing members. Nail the folded sides to the top of the

framing. (Figure 36)

ST926

Selkirk Support Box

6/07

Two Part Square

Trim Plate

Support Box

Support Box Collar

ST926

Figure 36 Support box.

A two-part square trim plate is provided to give a nished

look once installed. Simply t the two halves of the trim

plate around the cathedral ceiling support box hanging be-

low the ceiling (overlapping if necessary) and screw them

to the ceiling. Both the ceiling support and cathedral ceiling

support can support a maximum of 40’ (12 m) of pipe.

Offsets:

If any offsets are necessary in the vertical system, an Off-

set Support (OS) should be installed directly above the

upper elbow of the offset. Install by attaching the offset

support band to the pipe with two #8 x 1/4” sheet metal

screws (minimum ) and secure the offset support straps to

surrounding structure. (Figure 37)

KT927

slkrk offset support

6/07

Nail to top of

framing

Offset Support

Strap

Offset Support

Collar

ST927

Figure 37 Offset support.

Supporting DIRECT-TEMP: Horizontal Support

Horizontal runs of Direct-Temp should be supported every

4’ (122 cm) of pipe. This can be done with the use of plumb-

ers strapping or the offset support.

Adjustable Length (AJ)

An Adjustable Length is available to accommodate instal-

lations where non-standard lengths are necessary. The ad-

justable length telescopes down over a standard length of

pipe and provides an extension range of 3

1

⁄2” (89 mm) to

10

1

⁄2” (267 mm). Install by sliding the inlet end of the ad-

justable length over the outlet end of a standard length of

pipe. After positioning the adjustable length appropriately,

secure it to the standard length with two (2) #8 x1/4” sheet

metal screws (provided). Seal the area between both the

top and bottom of the adjustable length outer wall and the

outer wall of the standard length with an approved silicone

sealant.

Fire Stopping

DIRECT-TEMP must be restopped wherever it passes

through oors, ceiling or walls. The only location where a

restop is not required is at the roof level. Both vertical sup-

port components with trim plates provide for restopping.

The wall thimble also acts as a restop. at other locations,

a restop spacer (FS) should be installed. In the attic the

restop should be placed on top of the joist framing to pre-

vent debris from falling into the joist framing. (Figure 38)

Horizontal Installation

1. Determine the appliance location. Refer to the appliance

manufacturer’s installation instructions for clearance to

combustible requirements, termination options, num-

ber of elbows, maximum length, etc. Then position the

appliance and plan vent routing accordingly. Consider

locating the appliance in a place where there will be no

22

Stardance® Direct Vent/Natural Vent Gas Heater

20306760