Technical data

33

ENGLISH

4. Remove the plugs and/or seals from the suction, delivery, ventila-

tion and bleeder openings in the engine, restoring it to a normal

state of use. Connect the turbocharger suction inlet to the air filter.

5. Connect the fuel circuits to the vessel’s fuel tank, completing the

operations as indicated in point 4. of PREPARING THE ENGINE

FOR A LONG PERIOD OF INACTIVITY. During filling operations,

connect the fuel return pipe to a collection tank, so as to prevent

any residual CFB protective fluid from flowing into the vessel’s fuel

tank.

6. Check the engine and fill it up with coolant as prescribed.

7. Start the engine and keep it running until the idling speed rate has

stabilised completely.

8. Check that the instruments on the on-board control panel/s are

showing plausible values, and that no alarms are shown.

9. Stop the engine.

10.Remove the ENGINE WITHOUT OIL signs from the engine and

from the on-board control panel.

INDICATIONS FOR INITIAL START-UP AND

START-UP AFTER A LONG PERIOD OF

INACTIVITY

1. Fill up the engine as prescribed in the table REFUELLING.

2. Introduce 1.5 litres of water into the sea water pump, to allow it to

draw properly.

3. Start the motor and after the initial start-up phase check that no flu-

id is leaking from the cooling circuit sleeves and no exhaust fumes

are leaking from the exhaust pipes.

4. Bleed the cooling circuit as follows:

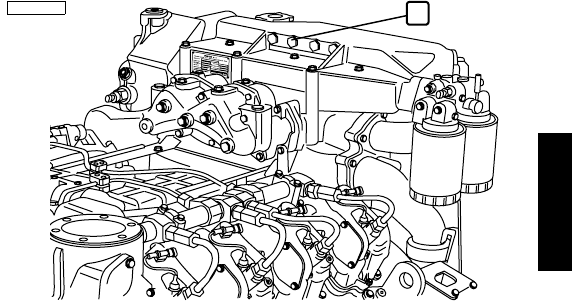

Stop the engine, carefully loosen the bleeder plug (1) to bleed the

expansion tank. When the operation has been completed, tighten

the plug, start the engine and leave it running for a few minutes.

Stop the engine and check the coolant level again, topping up if nec-

essary.

Ensure that any fluid coming out is not dispersed into the environ-

ment.

1

05_123_V