Service manual

Table Of Contents

- COVER

- CAUTION

- Safety precautions

- CONTENTS

- 1-1 Specifications

- 1-2 Handling Precautions

- 1-3 Installation

- 1-4 Maintenance mode

- 1-5 Trouble Shooting

- 1-5-1 Paper misfeed detection

- 1-5-2 Self-diagnosis

- 1-5-3 Image formation problems

- (1) No image appears (entirely white).

- (2) No image appears (entirely black).

- (3) Image is too light.

- (4) Background is visible.

- (5) A white line appears longitudinally.

- (6) A black line appears longitudinally.

- (7) A black line appears laterally.

- (8) One side of the copy image is darker than the other.

- (9) Black dots appear on the image.

- (10)Image is blurred.

- (11)The leading edge of the image is consistently misaligned with the original.

- (12)The leading edge of the image is sporadically misaligned with the original.

- (13)Paper creases.

- (14)Offset occurs.

- (15)Image is partly missing.

- (16)Fixing is poor.

- (17)Image is out of focus.

- (18)Image center does not align with the original center.

- (19)Image is not square.

- (20)Image contrast is low (carrier scattering).

- 1-5-4 Electrical problems

- (1) The machine does not operate when the main switch is turned on

- (2) The drive motor does not operate when (C200)

- (3) The scanner motor does not operate.

- (4) The toner feed motor does not operate

- (5) Cooling fan motor 1 does not operate

- (6) Cooling fan motor 2 does not operate

- (7) Cooling fan motor 3 does not operate

- (8) The drawer motor does not operate

- (9) The registration clutch does not operate

- (10) The upper paper feed clutch does not operate

- (11) The lower paper clutch does not operate

- (12) Paper feed clutch (ST) 1 does not operate

- (13) Paper feed clutch (ST) 2 does not operate

- (14) The bypass paper feed clutch does not operate

- (15) The cleaning lamp does not turn on

- (16) The exposure lamp does not turn on

- (17) The exposure lamp does not turn off

- (18) The fixing heater does not turn on (C610)

- (19) The fixing heater does not turn off

- (20) Main charging is not performed

- (21) Transfer charging is not performed

- (22) No developing bias is output

- (23) The original size is not detected

- (24) The original size is not detected correctly

- (25) The message requesting papaer to be loaded is shown when paper is present

- (26) The message requesting papaer to be loaded is shown when paper is present in the upper drawer

- (27) The message requesting papaer to be loaded is shown when paper is present in the lower drawer

- (28) The size of paper in the upper drawer is not displayed correctly

- (28) The size of paper in the upper drawer is not displayed correctly

- (29) The size of paper in the lower drawer is not displayed correctly

- (30) The printing width of the paper on the bypass is not detected correctly

- (31) A paper jam in the paper feed, paper conveying or fixing section is indicated when the main switch is turned on

- (32) The message requesting covers to be closed is displayed when the front cover, paper conveying unit and lower drawer left

- (33) Others

- 1-5-5 Mechanical problems

- 1-6 Assembly and disassembly

- 1-6-1 Precautions for assembly and disassembly

- 1-6-2 Paper feed section

- (1) Detaching and refitting the upper and lower paper feed pulleys

- (2) Detaching and refitting the bypass paper feed pulley

- (3) Detaching and refitting the left registration cleaner assembly

- (4) Detaching and refitting the right registration cleaner assembly

- (5) Detaching and refitting the bypass paper width switch

- (6) Adjustment after roller and clutch replacement

- 1-6-3 Optical section

- (1) Detaching and refitting the exposure lamp

- (2) Detaching and refitting the scanner wires

- (3) Detaching and refitting the laser scanner unit

- (4) Adjusting the skew and vertical shifting of the laser scanner unit

- (5) Detaching and refitting the ISU (reference)

- (6) Adjusting the position of the ISU (reference)

- (7) Adjusting the longitudinal squareness (reference)

- (8) Adjusting magnification of the scanner in the main scanning direction

- (9) Adjusting magnification of the scanner in the auxiliary scanning direction

- (10) Adjusting the scanner leading edge registration

- (11)Adjusting the scanner center line

- (12) Adjusting the margins for scanning an original on the contact glass

- 1-6-4 Main charging section

- 1-6-5 Drum section

- 1-6-6 Developing section

- 1-6-7 Transfer section

- 1-6-8 Cleaning section

- 1-6-9 Fixing section

- 1-7 Requirements on PCB Replacement

- 2-1 Electrical Parts Layout

- 2-2 Electrical parts layout

- 2-3 Operation of the PCBs

- 2-4 Appendixes

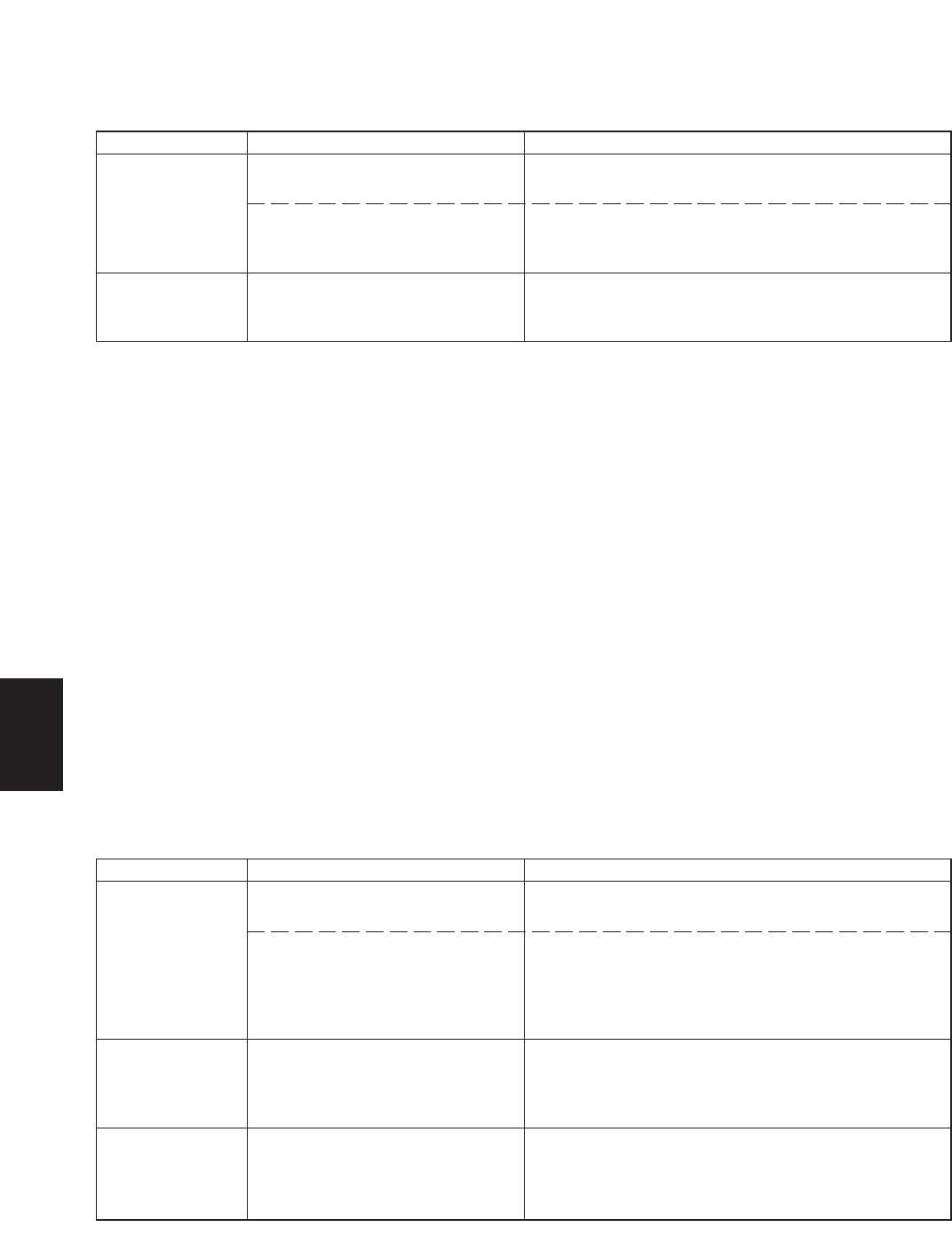

2AV/X

1-7-2

1-7

• - • - • -

•: On for 0.25 s

-: Off for 0.25 s

• - • – • - • –

•: On for 0.25 s

-: Off for 0.25 s

–: Off for 1 s

Off

• - • - • -

•: On for 0.25 s

-: Off for 0.25 s

Off

8. Turn the main switch off and disconnect the power plug.

9. Remove the memory tool PCB.

10. Replace the main PCB.

• After replacing the main PCB (writing the machine data)

11. Insert the power plug and turn the main switch on.

12. Upgrade the firmware on the main PCB and operation unit PCB (20 cpm copier only). See pages 1-7-3 and 5.

13. Turn the main switch on.

14. Enter maintenance mode.

15. Run maintenance item U020.

16. Run maintenance item U252 and set the destination.

17. Run maintenance item U917 and select “WRITE”.

18. Exit maintenance mode.

19. Turn the main switch off and disconnect the power plug.

20. Insert the memory tool PCB into the copier and connect its CN1 to CN31 on the main PCB.

Note:

On the 15 cpm copier, insert the memory tool PCB along the upper and lower guides.

On the 20 cpm copier, take care not to allow the memory tool PCB to make contact with the metal components of the copier.

21. Insert the power plug and turn the main switch on. LED1 (green) on the memory tool PCB flashes (on for 0.5 s → off for

0.5 s → on for 0.5 s → off for 0.5 s → on for 1 s → off for 0.5 s) for approximately 10 seconds and the machine data on

the NVRAM will be written to the SRAM on the main PCB.

22. When flashing LED1 (green) on the memory tool PCB remains lit, writing of the machine data is complete.

If an error occurs while the machine data is being written, LED1 (green) flashes and goes off in the patterns given below

according to the nature of the error. Remove the memory tool PCB and perform the respective corrective measures and

then write the machine data again.

6. Insert the power plug and turn the main switch on. LED1 (green) on the memory tool PCB flashes (on for 1 s → off for 1 s)

for approximately 10 seconds and the machine data on the SRAM of the main PCB will be backed up on the NVRAM.

7. When flashing LED1 (green) on the memory tool PCB remains lit, backing up of machine data is complete.

If an error occurs while the machine data is being backed up, LED1 (green) flashes and goes off in the patterns given

below according to the nature of the error. Remove the memory tool PCB and perform the respective corrective

measures and then back up the machine data again.

“WRITE” is selected in maintenance

item U917.

Since the NVRAM contains data

from the previous operation, data

cannot be written to it.

The machine data was not trans-

mitted from the SRAM on the main

PCB to the NVRAM correctly.

Run maintenance item U917 and select “READ”.

Replace the NVRAM on the memory tool PCB and back

up the machine data again.

Turn the main switch off and on and back up the machine

data again. If the error persists, replace the NVRAM.

LED1 Description Corrective measures

Run maintenance item U917 and select “WRITE”.

Replace the NVRAM on the memory tool PCB and then

back up the machine data again.

Replace the NVRAM on the memory tool PCB and back

up the machine data again.

Turn the main switch off and on and write the machine

data again. If the error persists, replace the main PCB.

“READ” is selected in maintenance

item U917.

An NVRAM with no backup data is

used. (LED1 flashes for 10 s in the

pattern on for 1 s and off for 1 s, and

then flashes in the pattern described

on the left.)

The machine data on the NVRAM

may be damaged (checksum error).

The machine data was not

transmitted from the NVRAM to the

SRAM on the main PCB correctly

(SRAM problem).

LED1 Description Corrective measures

23. Remove the memory tool PCB.