Operating instructions

OM-HY-6E

4

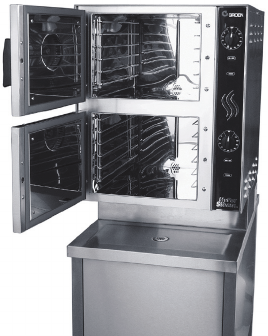

The HY-6E has two independent cavities, each

with its own base-mounted steam generator.

(New model shown)

Equipment Description

Your Groen HY-6E HyPerSteam Convection Steamer is

designed to give years of service. It has two stainless

steel cavities (cooking chambers) which are served by

twin, independent atmospheric steam generators which

are electrically-heated. A powerful blower circulates the

steam in each cavity to increase heating efficiency.

Each cavity holds up to three steam table pans (12" x 20"

x 2½"). An 18 gauge stainless steel cas

e encloses the

cavities, the steam generators and the control

compartment that houses electrical components. Door

hinges are reversible (the doors may be set to open from

the left or right). Operating Controls are on the front

panel.

HY-6E steamers are equipped with fully electronic

controls and a button-activated, preprogrammed CLEAN

cycle. The On-Off switch is a touch pad control, and the

distinctive symbol for steam is integrated into the panel

design.

The drain system includes a spray condenser, which

helps keep steam from escaping down the

condensate

drain.

Water Conditioning

4

OM-HY-6E

It is essential to supply the steam generator with water

that will not form scale or cause corrosion. Even

though the steam generator is engineered to minimize

scale formation and the effects of corrosion, their

development depends on the quality of your water and

the number of hours per day you operate the equip-

ment.

Most water supplies are full of minerals and chemicals

which are not suitable for use in a steam generator.

Water quality varies from state to state and city to city.

It is necessary that you know and understand the

quality of the water you are using. Your water utility

can tell you about the minerals and chemicals in your

water. The water going to the steam generator should

be within these guidelines

Water Pressure 30-60 psi

PH 7 to 9

Hardness less than 60 ppm

TDS 30 to 60 ppm

Chlorine and Chloramine less than 0.1 ppm

Total Chloride less than 30 ppm

Silica less than 12 ppm

Undissolved Solids less than 5 microns

1. Do not rely on unproven water treatments which are

sold for scale prevention or scale removal. They

don’t always work. The best way to prevent scale is

to supply the purest possible water (30 - 60 ppm

TDS).

2. If your water contains scale-forming minerals, as

most water does, use a well-maintained water

softener. Whether an exchangeable softener

cartridge or a regenerating system is chosen, a

regular exchange schedule is essential.

3. Installing a water meter between the softener and

the steamer will provide an accurate gauge of water

use, and will help determine when to exchange

cartridges or regenerate the softener. Using a water

softener will provide longer generator life, higher

steam capacity, and reduce maintenance require-

ments.

4. If you notice a slowdown in steam production, have

the unit checked for scale build-up. Heavy scale

reduces the unit’s ability to boil water and can even

cause heating elements in the steam generator to

overheat and burn out.