Data Sheet

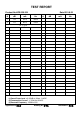

6.Environment Test Method

NO. ITEM TEST CONDITION AND REQUIREMENT

1

High Temperature

Test (Storage)

After being placed in a chamber with 802ºC for 96 hours and then

being placed in normal condition for 2 hours.

Allowable variation of SPL after test: 10dB.

2

Low Temperature

Test (Storage)

After being Placed in a chamber with -302ºC for 96 hours and

then being placed in normal condition for 2 hours.

Allowable variation of SPL after test: 10dB.

3 Humidity Test

After being Placed in a chamber with 90-95% R.H. at 402ºC for

96 hours and then being placed in normal condition for 2 hours.

Allowable variation of SPL after test:

10dB.

4

Temperature

Cycle

Test

The part shall be subjected to 5 cycles. One cycle shall be consist

of:

Allowable variation of SPL after test:

10dB.

5 Drop Test

Drop on a hard wood board of 4cm thick, any directions ,6 times,

at the height of 100cm. Allow

able variation of SPL after test:

10dB.

6 Vibration Test

After being applied vibration of amplitude of 1.5mmwith 10 to 55

Hz

band of vibration frequency to each of 3 perpendicular

directions for 2 hours . Allowable variation of SPL after test: 10dB.

7

Solder ability

Test

Lead terminals are immersed in rosin for 5 seconds and then

immersed in solder bath of +3005ºC for 31 seconds.90% min.

lead terminals shall be wet with solder

(Except the edge of

terminals).

8

Terminal / Wire

Strength

Pulling Test

The force of 9.8N(1.0kg) is applied to each terminal in axial

direction for 10 seconds. No visible damage and cutting off.

7.Reliability Test

Continuous life test:

250 Hours continuous operating at +70 ºC with maximum rated voltage applied .

Intermittent life test:

Aduty cycle of 1 minute on, 5 minutes off,a minimum of 10000 times at temperature +25 ºC

2

- 30ºC

+80ºC

+25ºC

+25ºC