Installation Guide

32

BALCONY GOOSENECK FITTINGS

These fittings come in 1-rise and 2-rise variations. The 2-rise

has a loose up easing. The up easing in the 1-rise variation

is factory-attached. To trim a 1-rise gooseneck, place the

fitting so that the rail-drop portion that is attached to the

up easing lies on a flat surface. This will likely require that

the top part of the fitting hang off of the flat surface. Place

the pitch block on its “rise” side and slide the “rake” edge

up to the underside of the up easing until it barely makes

contact. Make a mark at this point. Place the pitch block on

the “run” edge and slide it along side of the up easing with

the “rake” edge facing the uncut end of the up easing. Align

the “rake” edge with the tangent point and draw a line that

transfers the “rake” edge to the fitting. This is the cut line.

The pitch block may be used as a support while making the

angled cut (see Fig. 16-2).

The 2-rise gooseneck consists of an up easing and a

transition assembly. The transition assembly must first be

attached to the balcony rail. Then the balcony rail section

must be placed so that it is aligned with the balcony

balus

tr

ade cent

er

line and the hole in the bottom of the

transition assembly is centered over the balcony newel

location. This whole assembly must also rest on temporary

blocks so that when the rake rail is placed on the noses of

the treads, the balcony rail will be in the correct relative

position. Use the following formula to calculate the height

of the temporary blocks:

S TEP

B.9a

SECTION B

3

1

GOOSENECK LANDING FITTINGS

These fittings consist of a loose up easing and a transition

piece that has an attached up easing on the upper end. Trim

the transition up easing first just as described in the Starting

Fitting section. Then join the upper section of rail to the

trimmed end of the transition piece. This assembly is then

clamped to the tread noses, centered on the balustrade

centerline. Then slide the assembly up or down the rake

until the hole in the bottom of the fitting is centered at the

intersection of the upper and lower balustrade centerlines.

The lower up easing needs to be attached to the lower rail

before it can be marked properly. With the handrail on a

flat surface, place the pitch block on its “rise” side and slide

the “rake” edge up to the underside of the up easing until it

barely makes contact. Make a mark at this point. (An

alternate way of finding the tangent point is to place the rail

assembly on the nose of the treads, centered on the

balustrade centerline, and slid it up the rake until the up

easing comes in contact with the rail-drop of the transition

piece that it is clamped on the upper flight. The point

wher

e cont

act is made is t

he t

angent point.) Place the pitch

block on the “run” edge and slide it along side of the up

easing with the “rake” edge facing the uncut end of the up

easing. Align the “rake” edge with the tangent point and

draw a line that transfers the “rake” edge to the fitting. This

is the cut line (see Fig. 16-2).

Once cut, this section is placed back on the tread noses and

moved over from the balustrade centerline just enough to

allo

w the lower assembly to pass by the rail-drop of the

transition piece. Slide the lower assembly up the rake until

the back of the lower up easing is flush with the back of the

rail-drop. Make a mark at the top of the up easing on the

rail drop and then cut the rail drop. The lower assembly is

now ready to join to the upper assembly.

SECTION B

S TEP

B.9a

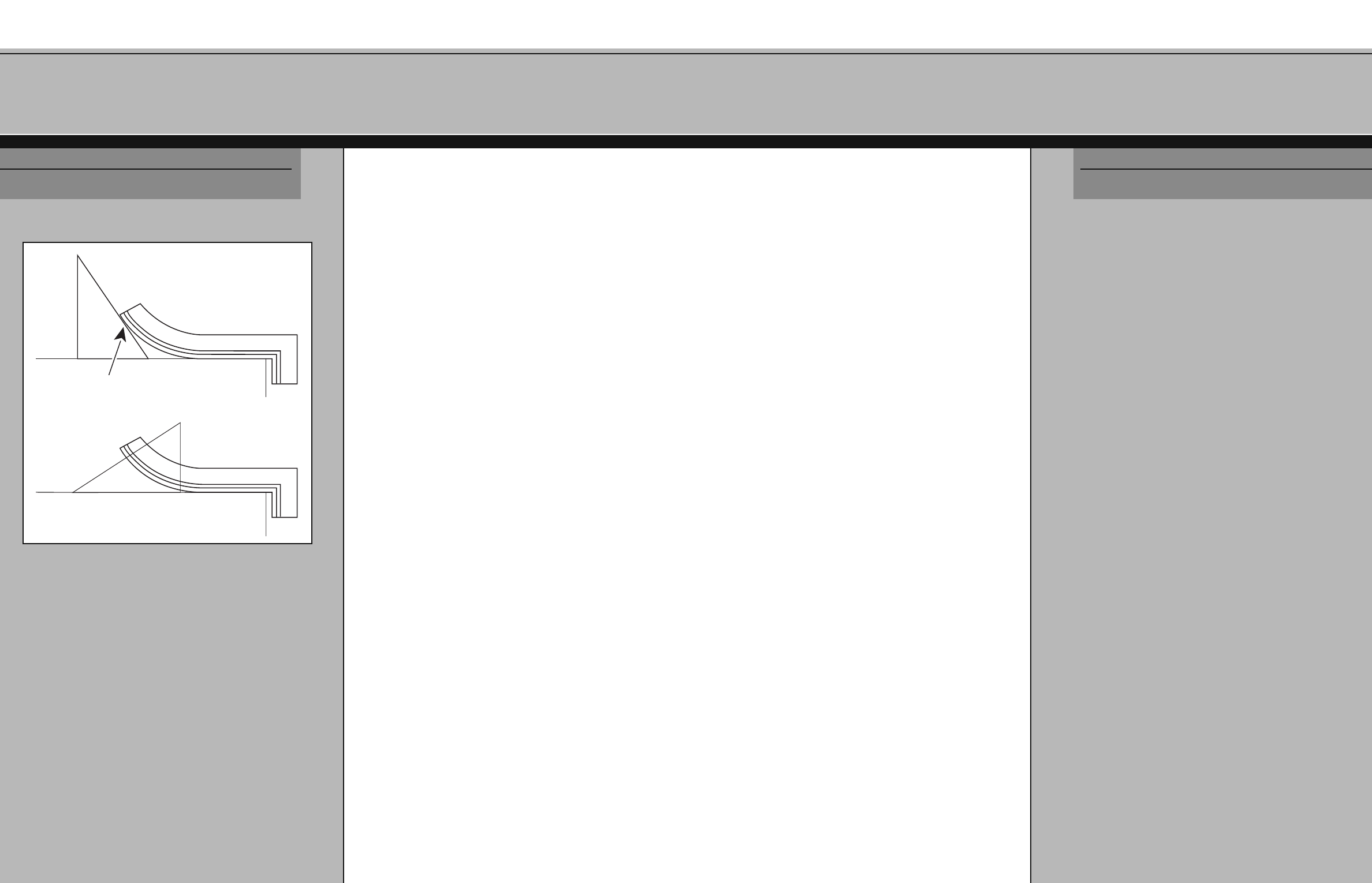

Rise

Mark the tangent (contact) point

Rise

Rake

Run

Rake

Run

Align with rake and complete mark

FIG. 16-2 - Marking the gooseneck for trimming

run

no. of balusters

=

distance between centerpoints of

balusters (and newels) throughout

the overall run (see Fig. 8-6)

run –

baluster square

thickness

distance from front

edge of tread to

center of first baluster

(see Fig. 8-5)

=

10" – is the same as 10" –

7

/

8

" = 9

1

/

8

"

1

3

/

4

"

2

10

1

/

2

"

3

= 3

1

/

2

"

2

tread

overhang

+

distance from top

of starting tread to bottom

of starting fitting

rake

rail

height

vertical

thickness

of rail

+

–

block

height

balcony

rail

height

balcony

rail

thickness

rake

rail

height

rake rail

thickness measured

on the plumb

=

–––

(

)