User guide

Table Of Contents

- 0-5143-CCr

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transtig 170Pi Power Source Controls, Indicators and Features

- 3.07 Shielding Gas Regulator Operating Instructions

- 3.08 Setup for TIG (GTAW) Welding

- 3.09 Foot Control Part No. W4015800 (Optional Accessory)

- 3.10 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- SECTION 6: KEY SPARE PARTS

- APPENDIX: TRANSTIG 170Pi CIRCUIT DIAGRAM

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY – January 2013

- WARRANTY SCHEDULE – January 2013

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transmig 175i Power Source Controls, Indicators and Features

- 3.14 Shielding Gas Regulator Operating Instructions

- 3.17 Setup for TIG (GTAW) Welding

- 3.18 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- AP0-5143-APENDIX

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY - JULY 2010

- WARRANTY SCHEDULE - JULY 2010

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

TRANSTIG 170Pi

Manual 0-5241 5-1 POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

SECTION 5:

POWER SOURCE PROBLEMS AND ROUTINE SERVICE

REQUIREMENTS

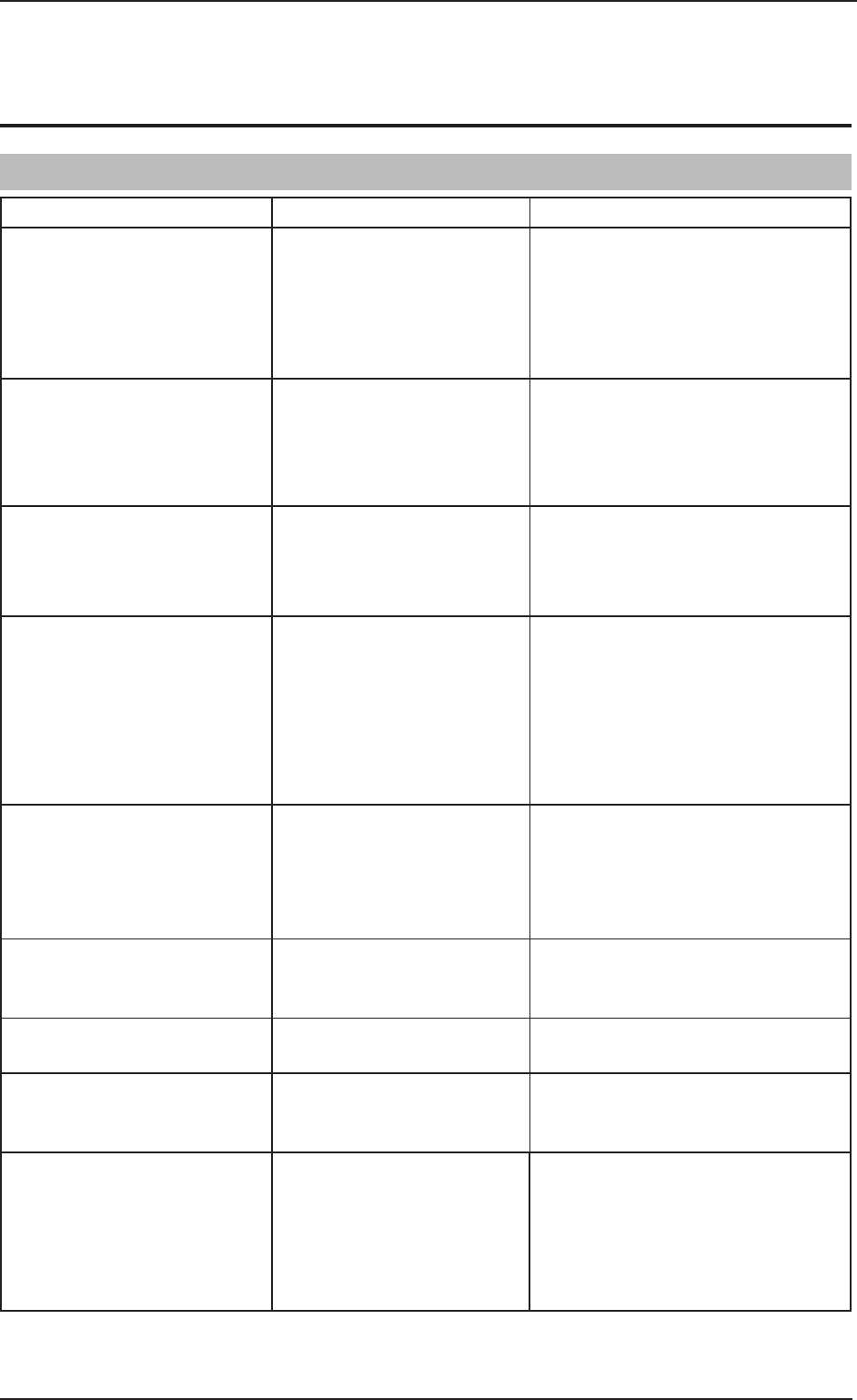

5.01 Power Source Problems

FAULT CAUSE REMEDY

1 Mains supply voltage is ON,

Amps Display is illumi-

nated however unit will not

commence welding when

the torch trigger switch is

depressed.

A Power source is not in the

correct mode of operation.

A Set the power source to the correct

mode of operation with the process

selection switch.

B Faulty torch trigger. B Repair or replace torch trigger

switch/lead.

2 Fault Indicator is illumi-

nated and unit will not

commence welding when

the torch trigger switch is

depressed.

Duty cycle of power source

has been exceeded.

Leave the power source switched

ON and allow it to cool. Note that

fault indicator must be extinguished

prior to commencement of welding.

3 Welding arc cannot be

established.

A Poor or no work lead

contact.

A Clean work clamp area and ensure

good electrical contact.

B Trigger switch faulty or

disconnected.

B Connect or repair trigger switch.

4 No gas flow in TIG mode. A Gas hose is damaged. A Replace or repair.

B Gas passage contains

impurities.

B Disconnect gas hose from the rear

of power source or wirefeeder and

blow out impurities.

C Gas regulator turned off. C Turn on regulator.

D Empty gas cylinder. D Replace gas cylinder.

5 Gas flow continues after

the torch trigger switch has

been released (TIG mode).

A Gas valve has jammed open

due to impurities in the gas

or the gas line.

A Have an accredited CIGWELD

service provider repair or replace

gas valve.

B Post flow is active in TIG

modes.

B Reduce post flow time

6 Amps Display will not il-

luminate and welding arc

cannot be established.

The mains supply voltage

has exceeded voltage limits

of the power source.

Ensure that the mains supply volt-

age is within 240VAC ± 15%.

7 TIG electrode melts when

arc is struck.

TIG torch is connected to

the (+) VE terminal.

Connect the TIG torch to the (-) VE

terminal.

8 Arc flutters during TIG

welding.

Tungsten electrode is too

large for the welding cur-

rent.

Select the correct size of tungsten

electrode. Refer to Table 4-3.

9 No HF on the welding

output

A HF TIG mode is not selected A Set the power source to HF TIG

mode of operation with the process

selection switch.

B Faulty HF pcb. B Have an accredited CIGWELD

service provider repair or replace

the HF pcb.