User guide

Table Of Contents

- 0-5143-CCr

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transtig 170Pi Power Source Controls, Indicators and Features

- 3.07 Shielding Gas Regulator Operating Instructions

- 3.08 Setup for TIG (GTAW) Welding

- 3.09 Foot Control Part No. W4015800 (Optional Accessory)

- 3.10 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- SECTION 6: KEY SPARE PARTS

- APPENDIX: TRANSTIG 170Pi CIRCUIT DIAGRAM

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY – January 2013

- WARRANTY SCHEDULE – January 2013

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transmig 175i Power Source Controls, Indicators and Features

- 3.14 Shielding Gas Regulator Operating Instructions

- 3.17 Setup for TIG (GTAW) Welding

- 3.18 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- AP0-5143-APENDIX

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY - JULY 2010

- WARRANTY SCHEDULE - JULY 2010

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

TRANSTIG 170Pi

Manual 0-5241 4-13 BASIC WELDING GUIDE

5 Portions of the

weld run do not

fuse to the surface

of the metal or

edge of the joint.

A Small electrodes used on

heavy cold plate.

A Use larger electrodes and preheat the plate.

B Welding current is too low. B Increase welding current.

C Wrong electrode angle. C Adjust angle so the welding arc is directed more

into the base metal.

D Travel speed of electrode

is too high.

D Reduce travel speed of electrode.

E Scale or dirt on joint

surface.

E Clean surface before welding.

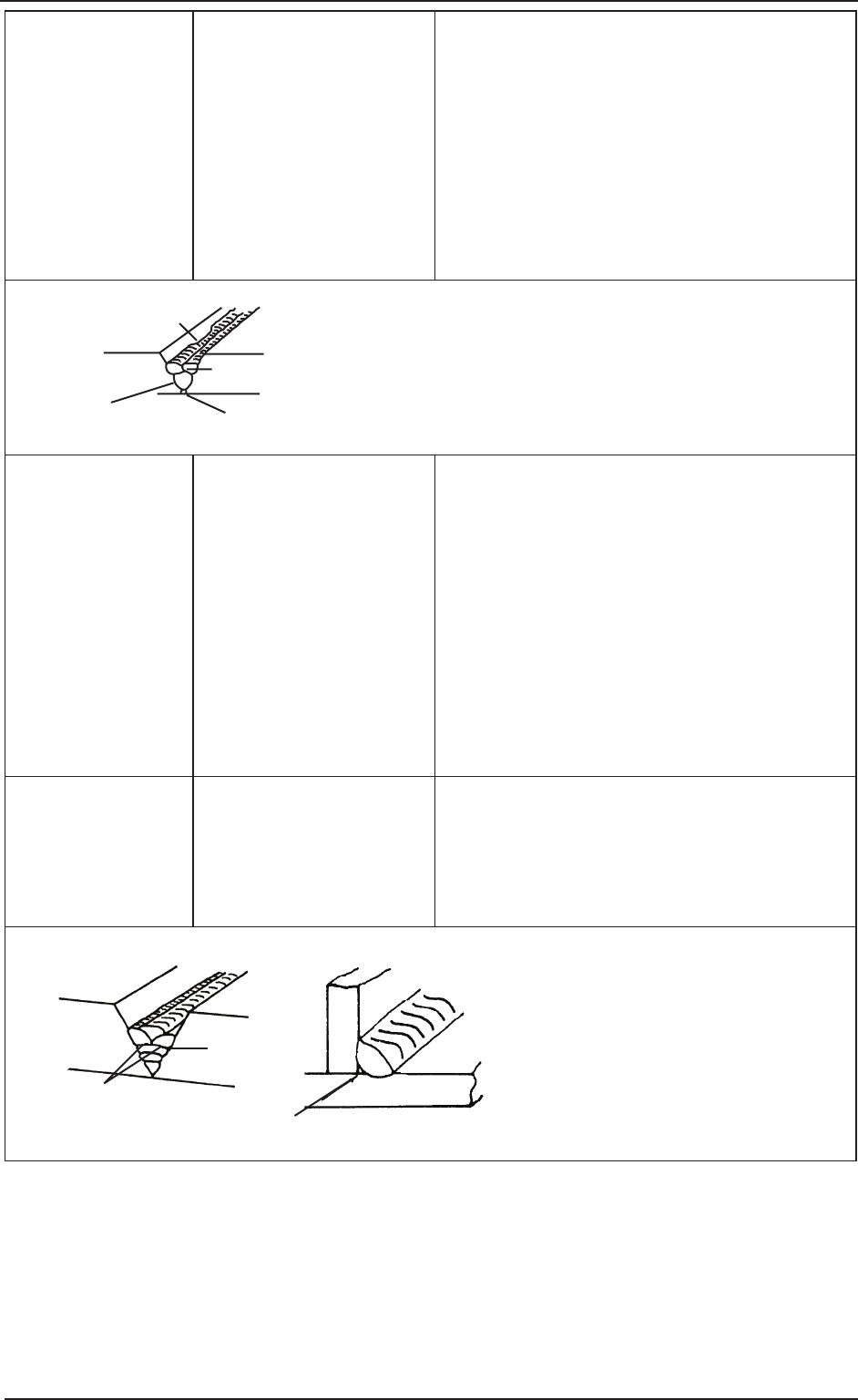

Art # A-05867_AC

Lack of

inter-run fusion

Lack of side fusion,

scale dirt, small electrode,

amperage too low

Lack of root fusion

Lack of fusion caused by dirt,

electrode angle incorrect,

rate of travel too high

Figure 2: Example of Lack of Fusion

6 Gas pockets or

voids in weld

metal (porosity)

A High levels of sulphur in

steel.

A Use an electrode that is designed for high sul-

phur steels.

B Electrodes are damp. B Dry electrodes before use.

C Welding current is too

high.

C Reduce welding current.

D Surface impurities such as

oil, grease, paint, etc.

D Clean joint before welding.

E Welding in a windy envi-

ronment.

E Shield the weld area from the wind.

F Electrode damaged ie flux

coating incomplete.

F Discard damaged electrodes and only use elec-

trodes with a complete flux coating.

7 Crack occurring in

weld metal soon

after solidification

commences

A Rigidity of joint. A Redesign to relieve weld joint of severe stresses

or use crack resistance electrodes.

B Insufficient throat thick-

ness.

B Travel slightly slower to allow greater build up in

throat.

C Weld current is too high. C Decrease welding current.

Not cleaned,

or incorrect

electrode

Slag

trapped in

undercut

Slag trapped in root

Art # A-05868_AC

Figure 3: Example of Slag Inclusion

Table 4-2: Welding Problems MMAW (Stick)