User guide

Table Of Contents

- 0-5143-CCr

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transtig 170Pi Power Source Controls, Indicators and Features

- 3.07 Shielding Gas Regulator Operating Instructions

- 3.08 Setup for TIG (GTAW) Welding

- 3.09 Foot Control Part No. W4015800 (Optional Accessory)

- 3.10 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- SECTION 6: KEY SPARE PARTS

- APPENDIX: TRANSTIG 170Pi CIRCUIT DIAGRAM

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY – January 2013

- WARRANTY SCHEDULE – January 2013

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transmig 175i Power Source Controls, Indicators and Features

- 3.14 Shielding Gas Regulator Operating Instructions

- 3.17 Setup for TIG (GTAW) Welding

- 3.18 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- AP0-5143-APENDIX

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY - JULY 2010

- WARRANTY SCHEDULE - JULY 2010

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

TRANSTIG 170Pi

BASIC WELDING GUIDE 4-6 Manual 0-5241

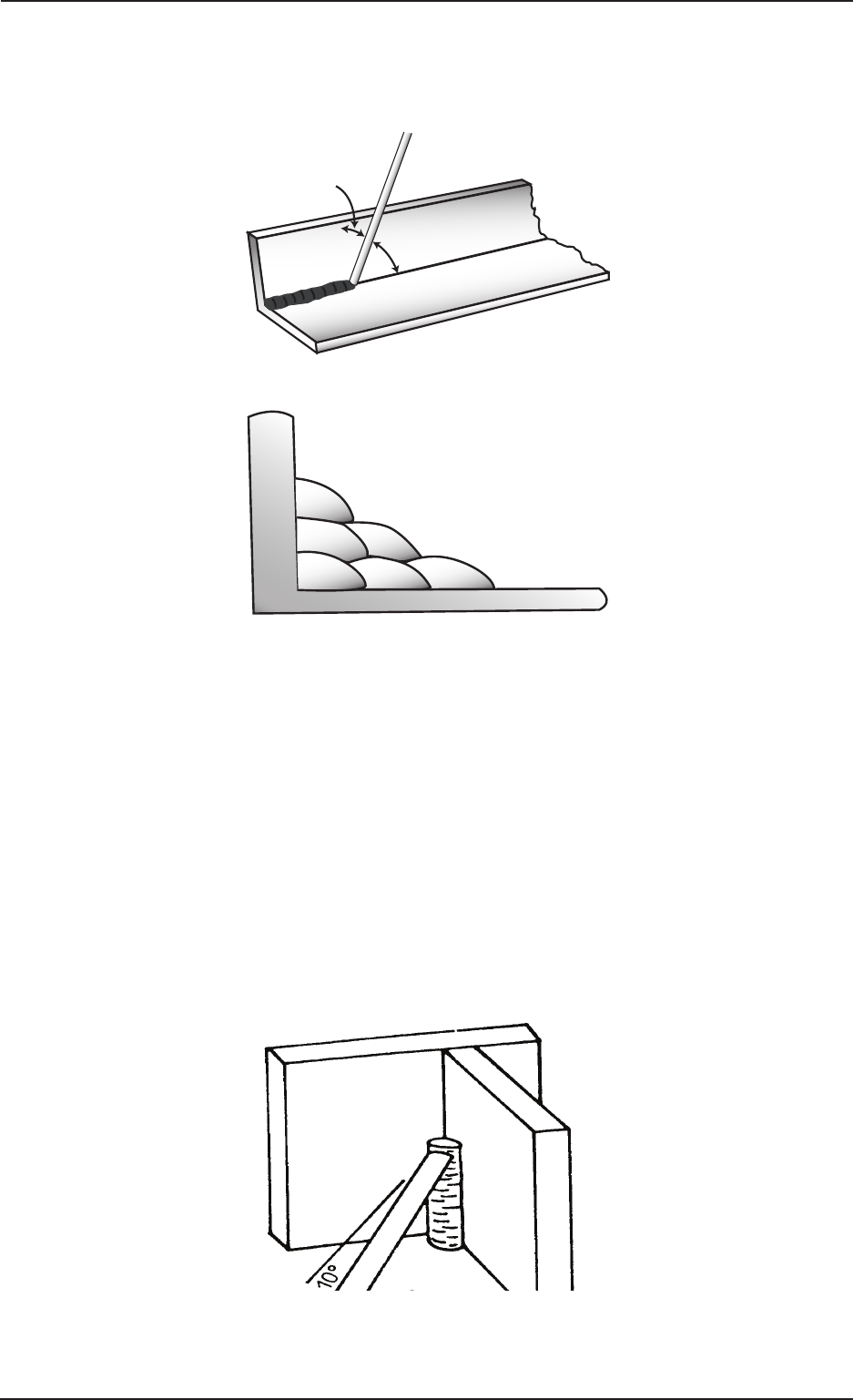

from the vertical. Some electrodes require to be sloped about 20º away from the perpendicular position

to prevent slag from running ahead of the weld. Refer to Figure 4-13. Do not attempt to build up much

larger than 6.4mm width with a 3.2mm electrode, otherwise the weld metal tends to sag towards the base,

and undercut forms on the vertical leg. Multi-runs can be made as shown in Figure 4-14. Weaving in HV

fillet welds is undesirable.

Art # A-07699_AB

45° from

vertical

60° - 70° from line

of weld

Figure 4-13: Electrode Position for HV Fillet Weld

Art # A-07700_AB

1

2

3

4

5

6

Figure 4-14: Multi-runs in HV Fillet Weld

C. Vertical Welds

1. Vertical Up

Tack weld a three feet length of angle iron to your work bench in an upright position. Use a 3.2mm

Ferrocraft 21 electrode and set the current at 100 amps. Make yourself comfortable on a seat in front

of the job and strike the arc in the corner of the fillet. The electrode needs to be about 10º from the

horizontal to enable a good bead to be deposited. Refer Figure 4-15. Use a short arc, and do not attempt

to weave on the first run. When the first run has been completed de-slag the weld deposit and begin

the second run at the bottom. This time a slight weaving motion is necessary to cover the first run and

obtain good fusion at the edges. At the completion of each side motion, pause for a moment to allow

weld metal to build up at the edges, otherwise undercut will form and too much metal will accumulate

in the centre of the weld. Figure 4-16 illustrates multi-run technique and Figure 4-17 shows the effects

of pausing at the edge of weave and of weaving too rapidly.

Art # A-07701

Figure 4-15: Single Run Vertical Fillet Weld