User guide

Table Of Contents

- 0-5143-CCr

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transtig 170Pi Power Source Controls, Indicators and Features

- 3.07 Shielding Gas Regulator Operating Instructions

- 3.08 Setup for TIG (GTAW) Welding

- 3.09 Foot Control Part No. W4015800 (Optional Accessory)

- 3.10 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- SECTION 6: KEY SPARE PARTS

- APPENDIX: TRANSTIG 170Pi CIRCUIT DIAGRAM

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY – January 2013

- WARRANTY SCHEDULE – January 2013

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

- SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Mains Supply Voltage Requirements

- 3.05 Electromagnetic Compatibility

- 3.06 Transmig 175i Power Source Controls, Indicators and Features

- 3.14 Shielding Gas Regulator Operating Instructions

- 3.17 Setup for TIG (GTAW) Welding

- 3.18 Setup for Manual Arc (MMAW) Welding

- SECTION 4: BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- AP0-5143-APENDIX

- CIGWELD - LIMITED WARRANTY TERMS

- TERMS OF WARRANTY - JULY 2010

- WARRANTY SCHEDULE - JULY 2010

- GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

TRANSTIG 170Pi

Manual 0-5241 3-9 INSTALLATION, OPERATION AND SETUP

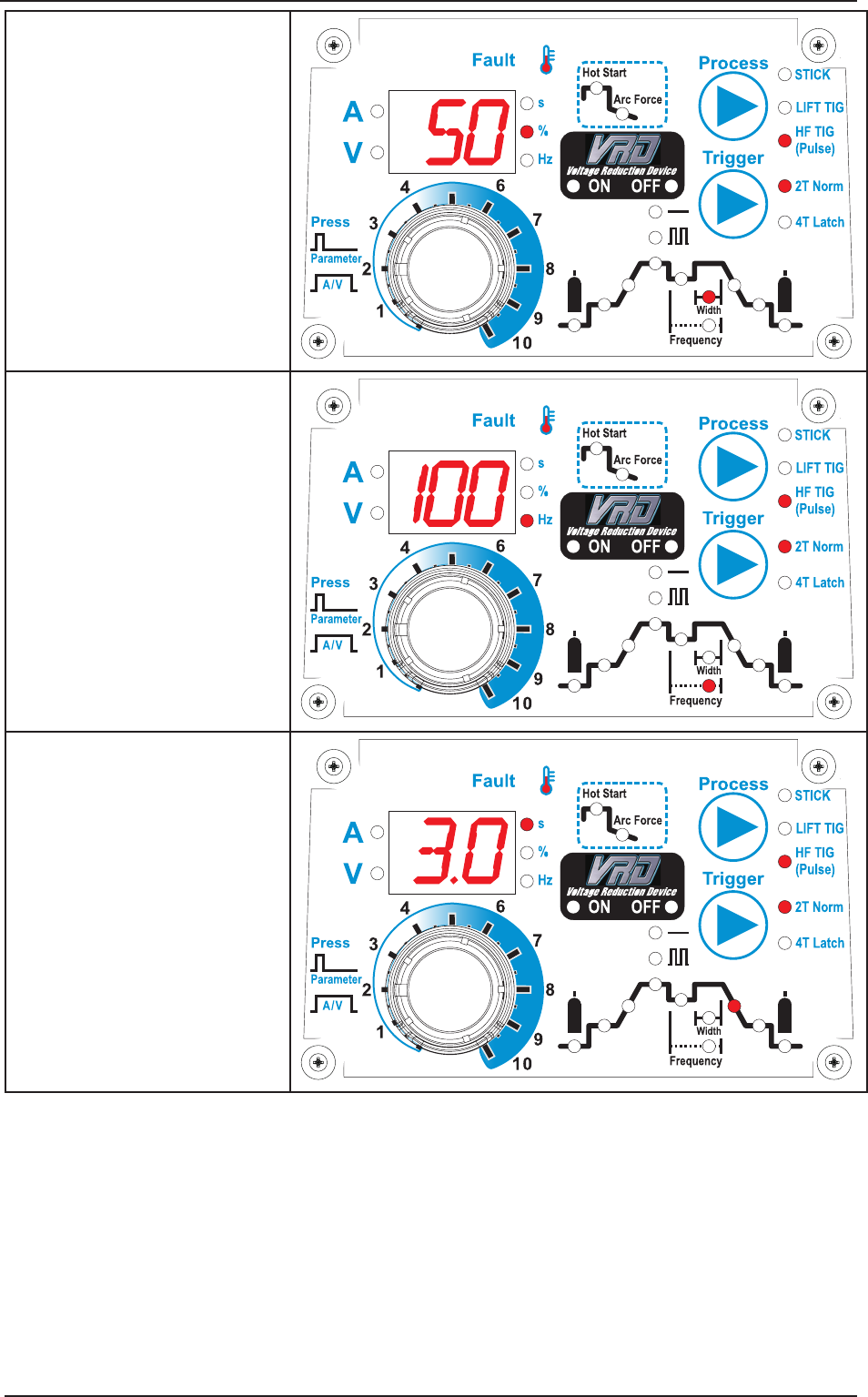

Pulse Width

This parameter sets the percentage

“on” time of the PULSE FREQUENCY

for BASE weld current when in

PULSE operating mode.

Range is 15 to 80%. Factory default

is 50%.

Pulse Frequency

This parameter sets the PULSE

FREQUENCY when in PULSE

operating mode.

Range is 0.5 to 500Hz. Factory

default is 100Hz.

Down Slope

This parameter operates in TIG

modes only and is used to set

the time for the weld current to

ramp down to the crater current.

This control is used to eliminate

the crater that can form at the

completion of a weld.

Range is 0.0 to 25.0 seconds.

Factory default is 3.0 seconds.