User guide

ARCMASTER

®

160 S

March 31, 200610-4

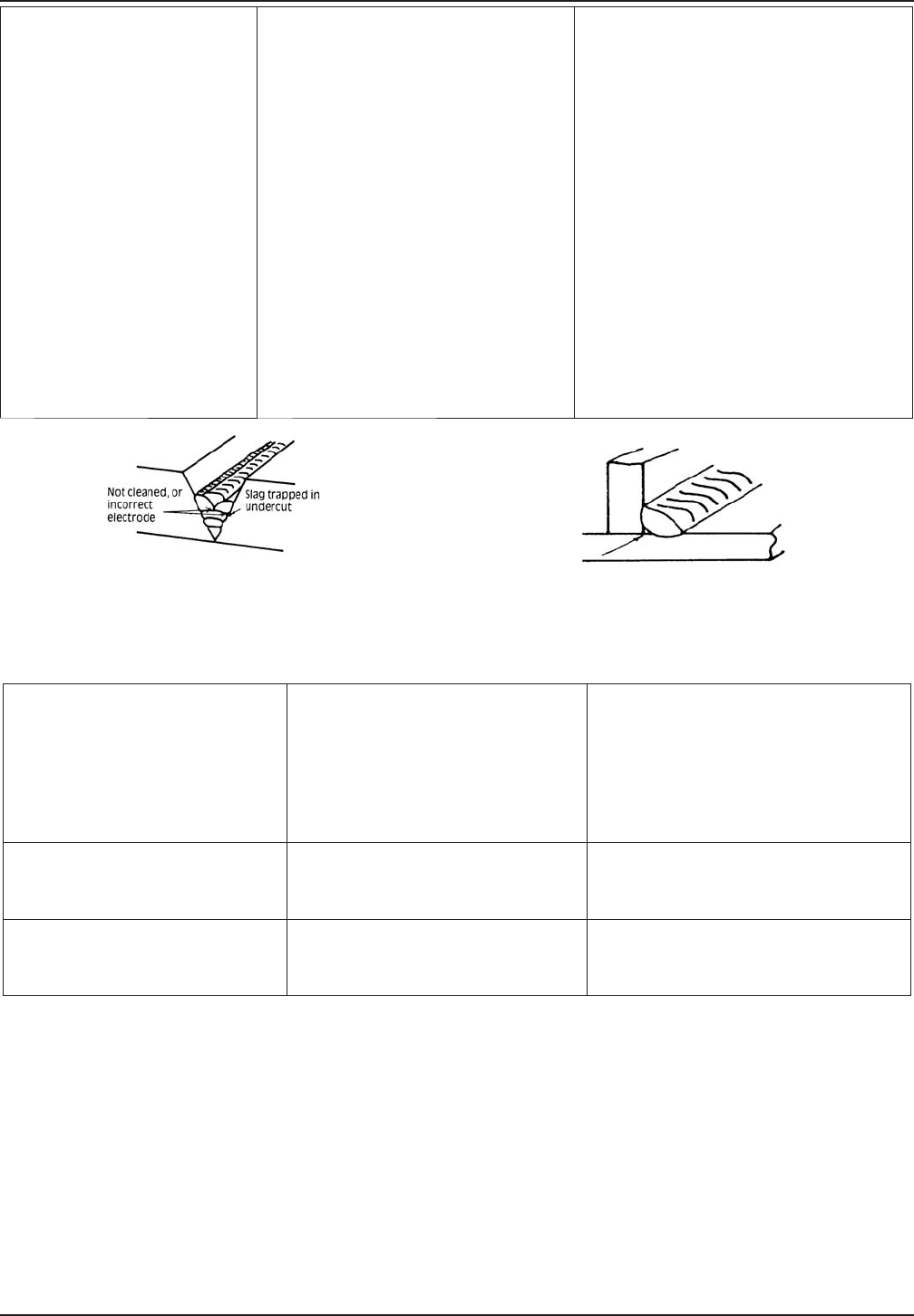

5. Non-metallic parti cles are

trapped in the weld metal

(slag inclusion).

A. Non-metallic particles may be trapped

in undercut from previous run.

A. If bad undercut is present, clean slag

out and cover with a run from a smaller

diameter electrode.

B. Joint preparation too restricted. B. Allow for adequate penetration and room

for cleaning out the slag.

C. Irregular deposits allow slag to be

trapped.

C. If very bad, chip or grind out

irregularities.

D. Lack of penetration with slag trapped

beneath weld bead.

D. Use smaller electrode with sufficient

current to give adequate penetration.

Use suitable tools to remove all slag

from corners.

E. Rust or mill scale is preventing full

fusion.

E. Clean joint before welding.

F. Wrong electrode for position in which

welding is done.

F. Use electrodes designed for position in

which welding is done, otherwise proper

control of slag is diffi cult.

Figure 10 – Examples of slag inclusion

10.03 Power Source Problems

Description Possible Cause Remedy

1. The welding arc cannot be

established

A.

B.

The Primary supply voltage has not

been switched ON.

The Welding Power Source switch

is switched OFF.

A.

B.

Switch ON the Primary supply

voltage.

Switch ON the Welding Power Source.

C. Loose connections internally. C. Have an Accredited Thermal Arc Service

Agent repair the connection.

2. Maximum output welding current

can not be achieved with nominal

Mains supply voltage.

Defective control circuit Have an Accredited Thermal Arc Service

Agent inspect then repair the welder.

3. Welding current reduces when

welding

Poor work lead connection to the

work piece.

Ensure that the work lead has a

positive electrical connection to the

work piece.