Product Manual

42

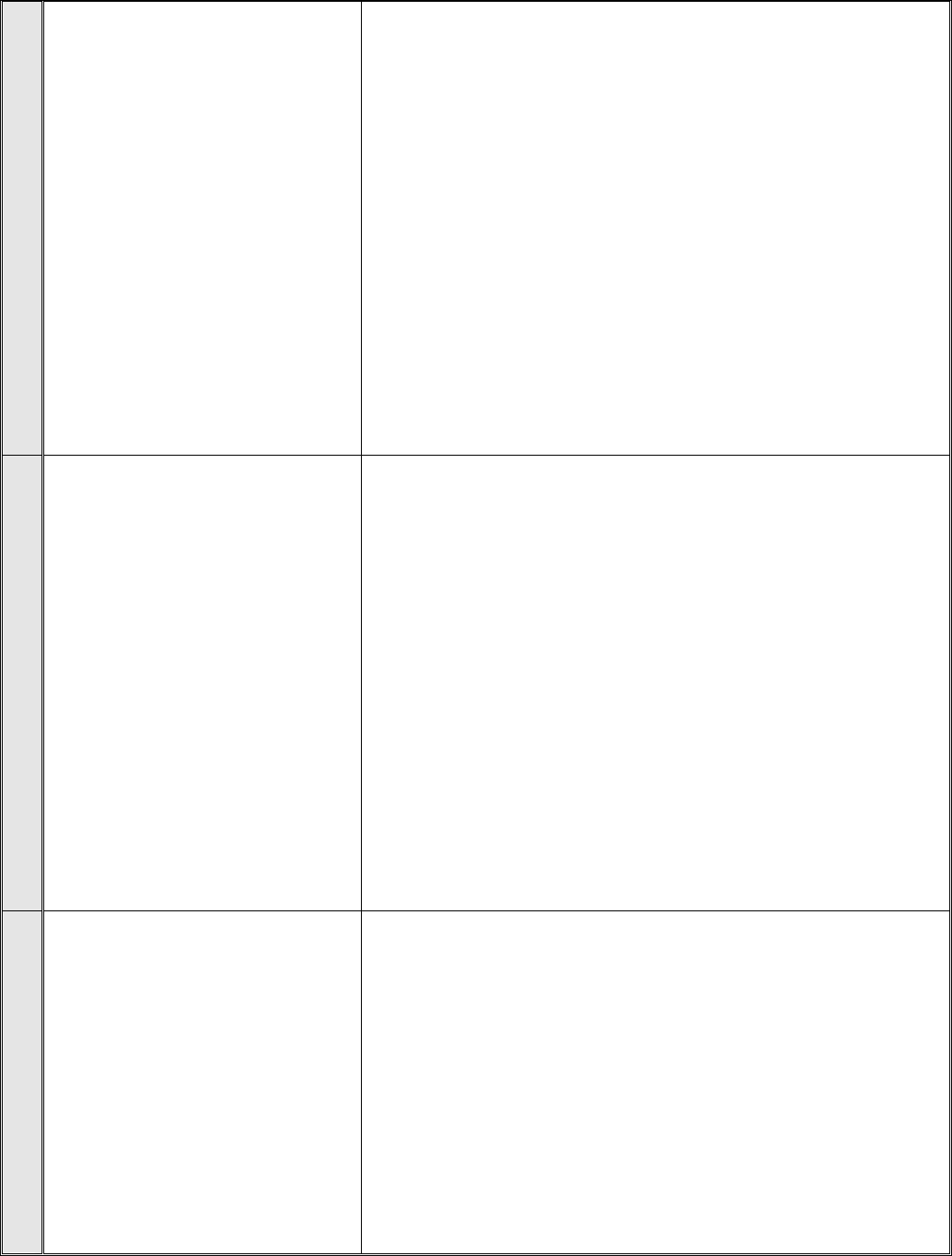

Corrections

8.1 Once the timer rings at the end of the sterile

cycle, immediately turn the multi-purpose

valve to the “Exh / Dry” position. Once

venting is complete, start the drying cycle.

8.2 Adjust loading according to "Maximum

Load Sizes" table in sec. 2.

8.3 Items to be sterilized should be separated

and not stacked. See preparations for

sterilization para. 6. A Tuttnauer Pouch Rack

is recommended.

8.4 Have a technician check the unit.

9.1 Check

table

2.6

for

correct

operating

voltages.

9.2 Check section 7 for correct operating

procedures. See sec. 4 for installation

instructions.

9.3 Tighten the door more, if leaking persists,

replace the door gasket.

9.4 Door bellows is leaking, have a technician

replace the bellows.

9.5 Follow procedure in section 8.5. If leaking

persists have technician replace the Safety

valve.

9.6 Sterilize fewer towels or gowns or adjust the

front of the unit higher to allow more water

into the chamber. See installation

instructions section 4.2/maximum load table

section 2.

9.7 Unit may be out of calibration or there is an

internal steam leak. Have a technician

check the unit.

9.8 Have a technician check the unit.

Possible Cause Checkup and Tests

8.1 The unit is not being vented immediately

after the sterile cycle.

8.2 Units may be overloaded.

8.3 The load may be too densely packed.

8.4 Units may not be heating properly.

9.1 Unit is not getting the correct voltage.

9.2 Chamber was not filled with the correct

amount of water.

9.3 Door gasket is leaking steam.

9.4 Steam is leaking at the closing device.

9.5 Safety Valve is leaking.

9.6 Items being sterilized are absorbing all

available steam (cloth towels or gowns).

9.7 Heat light goes out before correct pressure

is reached.

9.8 One or more of the heating elements is bad.

Symptom

8. Wrapped or bagged items do

not dry. See also section 10.32

and section 8.8.

9. Unit does not reach the proper

operating pressure.