Technical Specifications

UP

UP

UP

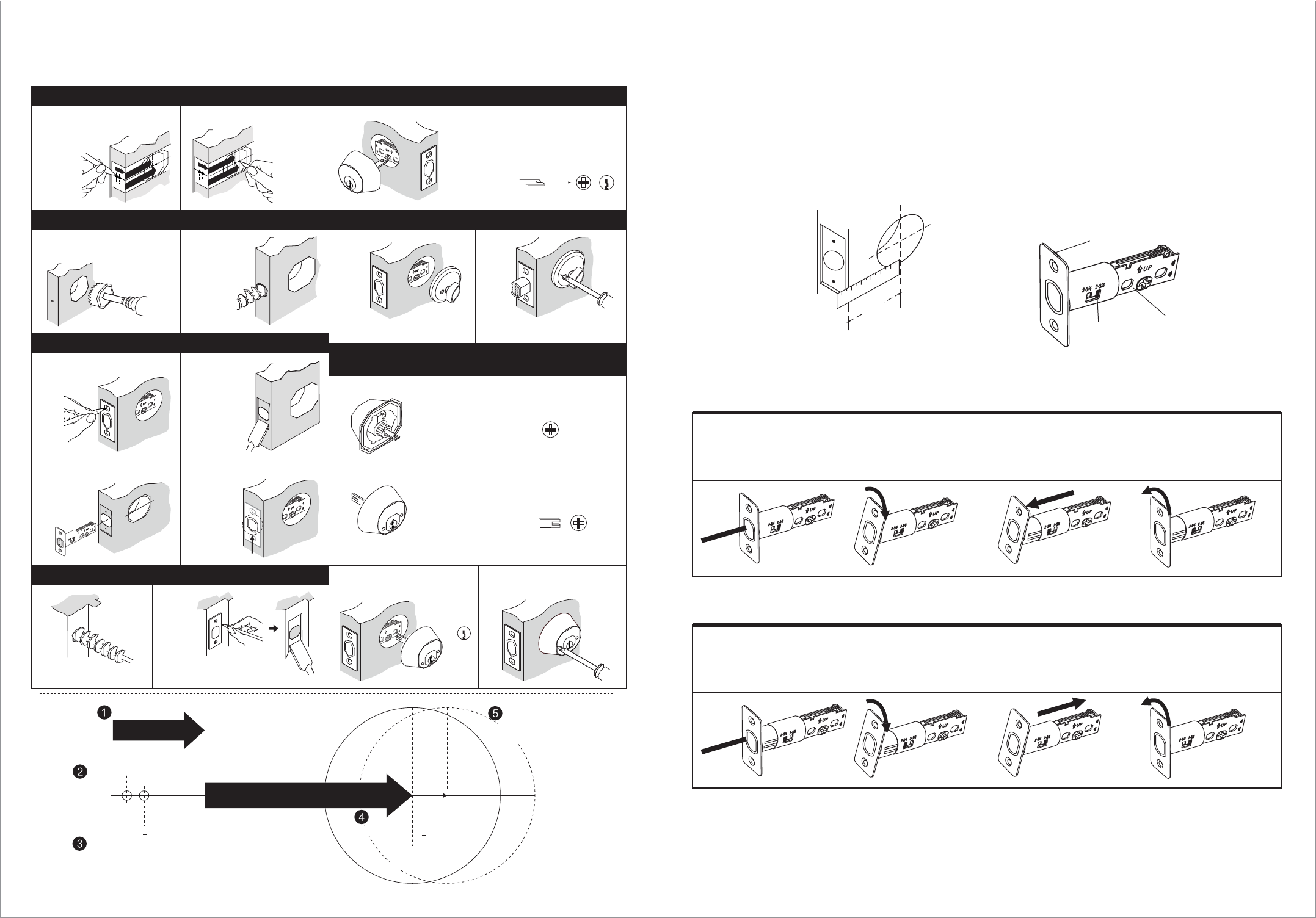

INSTRUCTIONS FOR INSTALLATION OF

SINGLE AND DOUBLE CYLINDER DEADLOCKS

FOR USE ON DOORS 1-3/8" TO 1-3/4" (35mm-45mm)

5.INSTALL EXTERIOR MECHANISM

TORQUE BLADE

SHOULD BE

HORIZONTALLY

INSERTED INTO

LATCH CRANK

A. Press cylinder side flush against door making certain

the torque blade is properly positioned in latch crank.

B. Tapped holes in mounting plate of exterior cylinder

should be lined up with latch holes. Key hole should

be in down position.

6.INSTALL INTERIOR MECHANISM

A. Slide thumb bar and interior rosette onto

torque blade.

B. Insert machine screws through holes

engaging holes in cylinder and tighten.

1" THROW

TURN

PIECE

Exterior half is fully assembled with exterior torque blade

EXTERIOR TORQUE BLADE

NOTE: The interior torque blade is inserted into the exterior blade.

INTERIOR TORQUE BLADE

A. Install interior cylinder

NOTE: This assembly is placed through latch first.

B. Press interior assembly flush against door

making certain the torque blade is

properly positioned

in latch hole. Key

hole should be in

down position.

C. Insert(2) two screws through countersunk

holes engaging holes in exterior cylinder

and tighten.

1.MARK DOOR

A. Fold and apply template to high edge of

door bevel and mark center of door edge

as indicated on

template at

the desired

height from

the floor.

B. Mark center hole on door face through

guide on template

for either 2-3/8"

(60mm) or

2-3/4"

(70mm)

backset.

2.DRILL HOLES

A. Drill thru door face as marked for lockset:

It is recommended that holes be drilled from

both sides to prevent spliting. Hole size is 2"

(50.8mm) for

standard

installations.

B. Drill 1"(25mm)

hole in center

of door edge

thru to

2"(50.8mm)

hole for

latch.

B. Chisel 1/8"

deep or until

latch face is

flush with

door edge.

C. Install deadbolt latch in

up position into

hole as shown

on latch insert

and tighten

screws.

D. For round face deadbolt press flush to

door edge

Bolt must

be vertically

aligned with

door edge

as indicated

by arrow.

4.INSTALL STRIKE

A. Bore 1" hole 1"minimum deep

for deadbolt.

B. Mortise 1/16" deep for strike

locating from 1" hole in door

insert and tighten screws.

UP

A. Insert latch in hole keeping it parallel to

face of door. Mark

outline and

remove latch.

UP

UP

TORQUE

BLADE

2-3/8" BACKSET

2-3/4" BACKSET

2-3/8" BACKSET

2-3/4" BACKSET

3.INSTALL LATCH

INSTRUCTIONS FOR INSTALLING

DOUBLE CYLINDER DEADLOCKS

FOR INSTALLING

DEADLOCKS

NOTE:

TEMPLATE MUST

BE PLACED ON

HIGH EDGE OF

DOOR BEVEL

MARK

PROPER

DOOR

THICKNESS

DRILL 1"(25mm)

HOLE IN EDGE OF DOOR

(2" IN DEPTH)

READ INSTRUCTIONS

1 "(45mm)THICK

DOOR

1 " 35mm

THICK

DOOR

2 "(70mm)

2 "(60mm)

FOLD HERE

2 /

8

"BACKSET

3

3

4

3

4

3

8

3

8

DRILL

2"(50.8mm)

HOLE

BACKSET

DISTANCE

MARK

UP

To adjust the backset from 2-3/8" to 2-3/4" follow these steps.

Retract the latch bolt.

Hold the latch tail and

rotate the faceplate

towards you.

Rotate the latch faceplate

away from you and check

to see if the notch is at

the 2-3/4" mark.

(A)

2-3/8" - or - 2-3/4"

(60 mm) (70 mm)

UP

Latch Faceplate

Latch Tail

Selecting the Proper Backset

The backset is the distance from the door edge to the center of the hole

To adjust the backset from 2-3/4" to 2-3/8" follow these steps.

Once the notch is in

the groove, pull the

latch faceplate away

from the latch tail.

Retract the latch bolt.

Hold the latch tail and

rotate the faceplate

towards you.

Rotate the latch faceplate

away from you and check

to see if the notch is at

the 2-3/8" mark.

Once the notch is in

the groove, push the

latch faceplate towards

the latch tail.

UP

UP

Notch

UP

UP

UP

UP

UP