User Manual

Table Of Contents

- 1 Features

- 2 First Steps with TMCL

- 3 TMCL and the TMCL-IDE — An Introduction

- 3.1 Binary Command Format

- 3.2 Reply Format

- 3.3 Standalone Applications

- 3.4 TMCL Command Overview

- 3.5 TMCL Commands by Subject

- 3.6 Detailed TMCL Command Descriptions

- 3.6.1 ROR (Rotate Right)

- 3.6.2 ROL (Rotate Left)

- 3.6.3 MST (Motor Stop)

- 3.6.4 MVP (Move to Position)

- 3.6.5 SAP (Set Axis Parameter)

- 3.6.6 GAP (Get Axis Parameter)

- 3.6.7 SGP (Set Global Parameter)

- 3.6.8 GGP (Get Global Parameter)

- 3.6.9 STGP (Store Global Parameter)

- 3.6.10 RSGP (Restore Global Parameter)

- 3.6.11 RFS (Reference Search)

- 3.6.12 SIO (Set Output)

- 3.6.13 GIO (Get Input)

- 3.6.14 CALC (Calculate)

- 3.6.15 COMP (Compare)

- 3.6.16 JC (Jump conditional)

- 3.6.17 JA (Jump always)

- 3.6.18 CSUB (Call Subroutine)

- 3.6.19 RSUB (Return from Subroutine)

- 3.6.20 WAIT (Wait for an Event to occur)

- 3.6.21 STOP (Stop TMCL Program Execution – End of TMCL Program)

- 3.6.22 SCO (Set Coordinate)

- 3.6.23 GCO (Get Coordinate)

- 3.6.24 CCO (Capture Coordinate)

- 3.6.25 ACO (Accu to Coordinate)

- 3.6.26 CALCX (Calculate using the X Register)

- 3.6.27 AAP (Accu to Axis Parameter)

- 3.6.28 AGP (Accu to Global Parameter)

- 3.6.29 CLE (Clear Error Flags)

- 3.6.30 EI (Enable Interrupt)

- 3.6.31 DI (Disable Interrupt)

- 3.6.32 VECT (Define Interrupt Vector)

- 3.6.33 RETI (Return from Interrupt)

- 3.6.34 Customer specific Command Extensions (UF0…UF7 – User Functions)

- 3.6.35 Request Target Position reached Event

- 3.6.36 TMCL Control Commands

- 4 Axis Parameters

- 5 Global Parameters

- 6 Hints and Tips

- 7 TMCL Programming Techniques and Structure

- 8 Figures Index

- 9 Tables Index

- 10 Supplemental Directives

- 11 Revision History

TMCM-3212 TMCL

™

Firmware Manual • Firmware Version V1.07 | Document Revision V1.04 • 2017-JUN-08

83 / 103

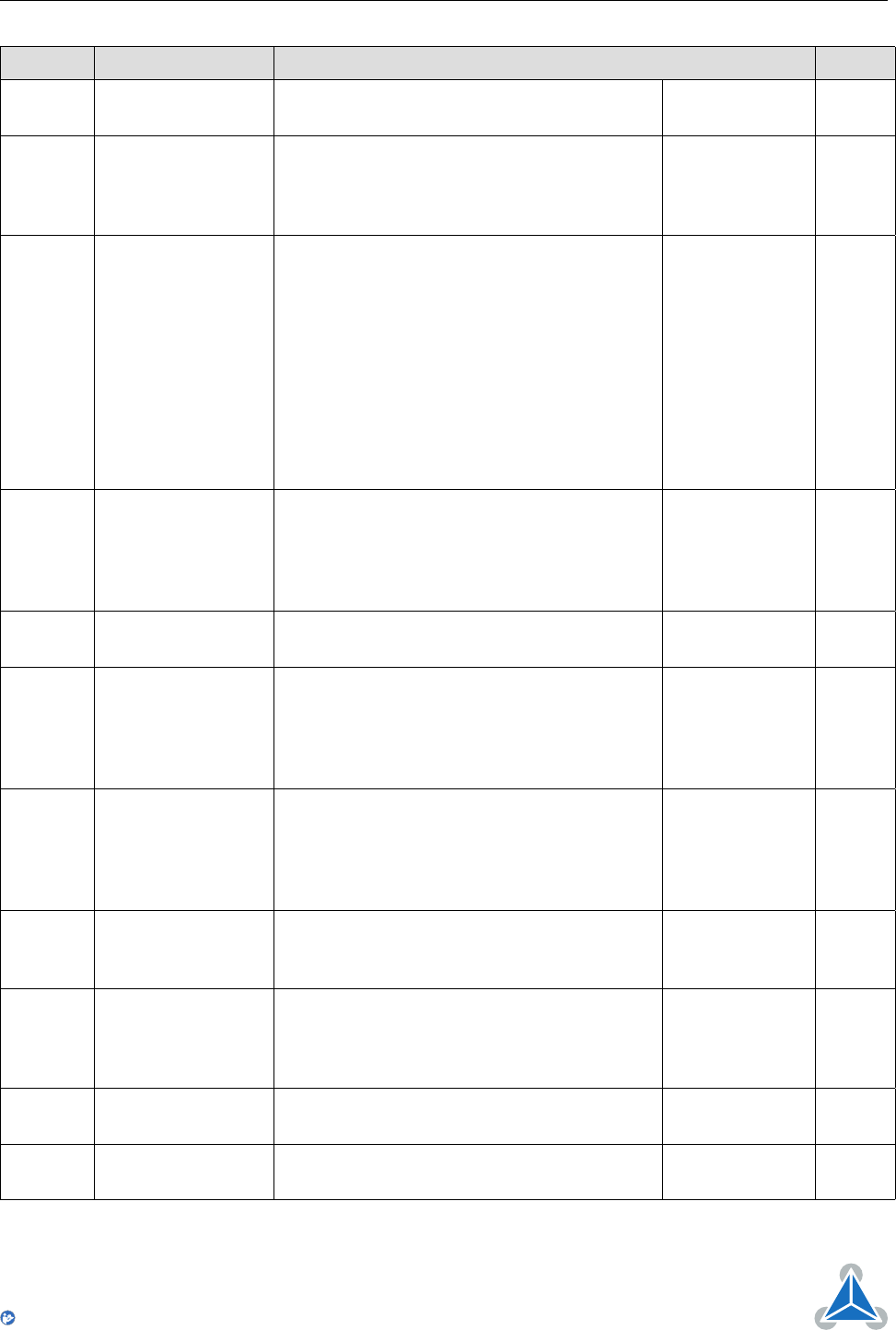

Number Global Parameter Description Range [Units] Access

76 Serial host

address

Host address used in the reply telegrams

sent back via RS485.

0. . . 255 RWA

77 Auto start mode

0 - Do not start TMCL application after

power up (default).

1 - Start TMCL application automatically af-

ter power up.

0/1 RWA

81 TMCL code

protection

Protect a TMCL program against disassem-

bling or overwriting.

0 - no protection

1 - protection against disassembling

2 - protection against overwriting

3 - protection against disassembling and

overwriting

When switching off the protection

against disassembling (changing this

parameter from 1 or 3 to 0 or 2, the

program will be erased first!

0/1/2/3 RWA

82 CAN heartbeat

Heartbeat for CAN interface. If this time

limit is up and no further command is re-

ceived the motor will be stopped. Setting

this parameter to 0 (default) turns off the

CAN heartbeat function.

0. . . 65535 RWA

83 CAN secondary

address

Second CAN ID for the module. Switched

off when set to zero.

0. . . 2047 RWA

84 Coordinate

storage

0 - coordinates are stored in RAM only (but

can be copied explicitly between RAM and

EEPROM)

1 - coordinates are always also stored in the

EEPROM

0/1 RWA

85 Do not restore

user variables

Determines if TMCL user variables are to be

restored from the EEPROM automatically on

startup.

0 - user variables are restored (default)

1 - user variables are not restored

0/1 RWA

87 Serial secondary

address

Second module (target) address for RS485.

Setting this parameter to 0 switches off the

seconndary address.

0. . . 255 RWA

128 TMCL application

status

0 - stop

1 - run

2 - step

3 - reset

0. . . 3 R

129 Download mode 0 - normal mode

1 - download mode

0/1 R

130 TMCL program

counter

Contains the address of the currently exe-

cuted TMCL command.

R

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.