User Manual

Table Of Contents

- 1 Features

- 2 First Steps with TMCL

- 3 TMCL and the TMCL-IDE — An Introduction

- 3.1 Binary Command Format

- 3.2 Reply Format

- 3.3 Standalone Applications

- 3.4 TMCL Command Overview

- 3.5 TMCL Commands by Subject

- 3.6 Detailed TMCL Command Descriptions

- 3.6.1 ROR (Rotate Right)

- 3.6.2 ROL (Rotate Left)

- 3.6.3 MST (Motor Stop)

- 3.6.4 MVP (Move to Position)

- 3.6.5 SAP (Set Axis Parameter)

- 3.6.6 GAP (Get Axis Parameter)

- 3.6.7 SGP (Set Global Parameter)

- 3.6.8 GGP (Get Global Parameter)

- 3.6.9 STGP (Store Global Parameter)

- 3.6.10 RSGP (Restore Global Parameter)

- 3.6.11 RFS (Reference Search)

- 3.6.12 SIO (Set Output)

- 3.6.13 GIO (Get Input)

- 3.6.14 CALC (Calculate)

- 3.6.15 COMP (Compare)

- 3.6.16 JC (Jump conditional)

- 3.6.17 JA (Jump always)

- 3.6.18 CSUB (Call Subroutine)

- 3.6.19 RSUB (Return from Subroutine)

- 3.6.20 WAIT (Wait for an Event to occur)

- 3.6.21 STOP (Stop TMCL Program Execution – End of TMCL Program)

- 3.6.22 SCO (Set Coordinate)

- 3.6.23 GCO (Get Coordinate)

- 3.6.24 CCO (Capture Coordinate)

- 3.6.25 ACO (Accu to Coordinate)

- 3.6.26 CALCX (Calculate using the X Register)

- 3.6.27 AAP (Accu to Axis Parameter)

- 3.6.28 AGP (Accu to Global Parameter)

- 3.6.29 CLE (Clear Error Flags)

- 3.6.30 EI (Enable Interrupt)

- 3.6.31 DI (Disable Interrupt)

- 3.6.32 VECT (Define Interrupt Vector)

- 3.6.33 RETI (Return from Interrupt)

- 3.6.34 Customer specific Command Extensions (UF0…UF7 – User Functions)

- 3.6.35 Request Target Position reached Event

- 3.6.36 TMCL Control Commands

- 4 Axis Parameters

- 5 Global Parameters

- 6 Hints and Tips

- 7 TMCL Programming Techniques and Structure

- 8 Figures Index

- 9 Tables Index

- 10 Supplemental Directives

- 11 Revision History

TMCM-3212 TMCL

™

Firmware Manual • Firmware Version V1.07 | Document Revision V1.04 • 2017-JUN-08

29 / 103

3.6.7 SGP (Set Global Parameter)

With this command most of the module specific parameters not directly related to motion control can be

specified and the TMCL user variables can be changed. Global parameters are related to the host interface,

peripherals or application specific variables. The different groups of these parameters are organized in

banks to allow a larger total number for future products. Currently, bank 0 is used for global parameters,

and bank 2 is used for user variables. Bank 3 is used for interrupt configuration.

All module settings in bank 0 will automatically be stored in non-volatile memory (EEPROM).

Info

For a table with parameters and values which can be used together with this

command please refer to section 5.

Internal function:

The specified value will be copied to the global parameter specified by the type and

bank number. Most parameters of bank 0 will automatically be stored in non-volatile memory.

Related commands: GGP, AGP.

Mnemonic: SGP <parameter number>, <bank>, <value>

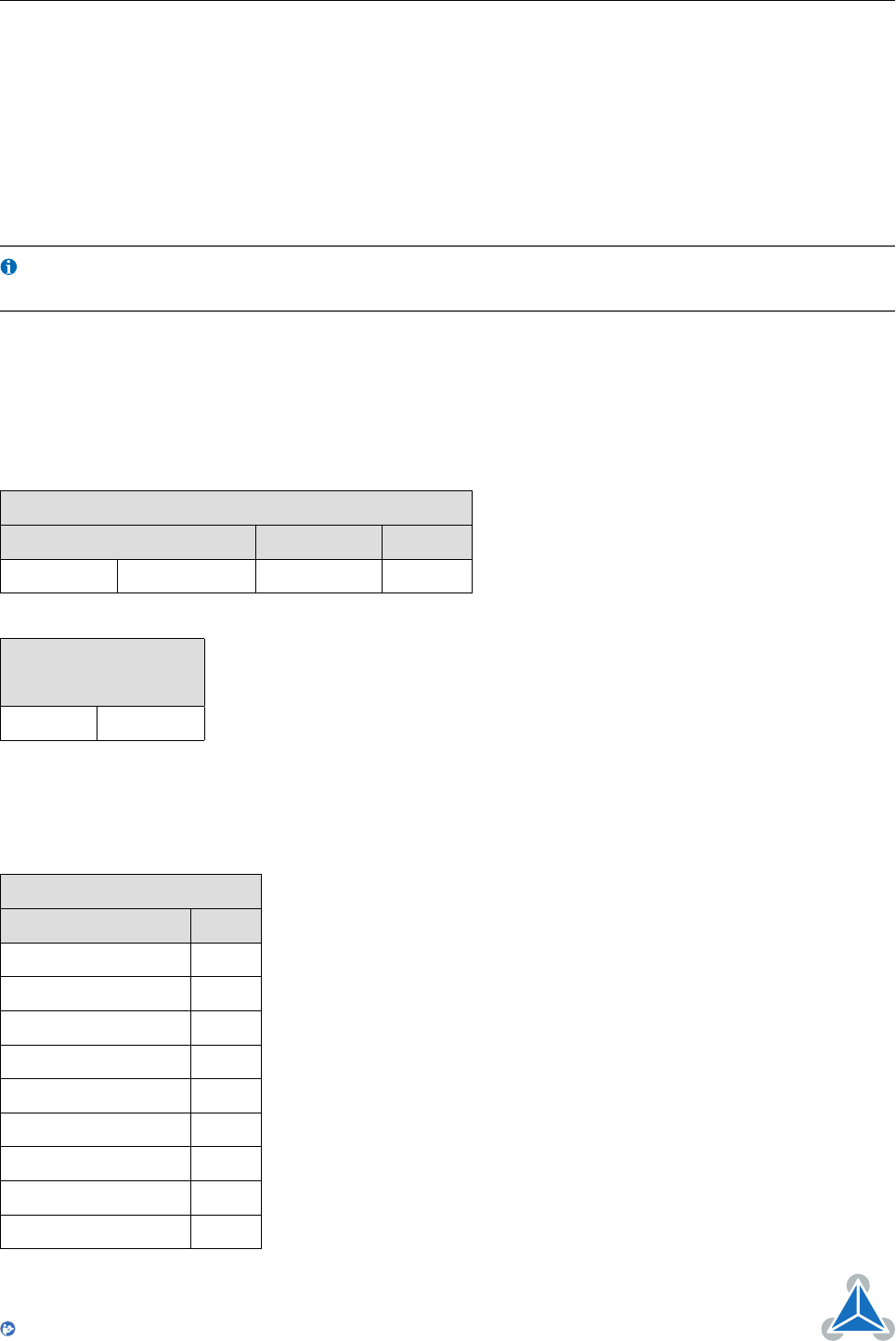

Binary Representation

Instruction Type Motor/Bank Value

9 see chapter 5 0/2/3 <value>

Reply in Direct Mode

Status Value

100 - OK don’t care

Example

Set the serial address of the device to 3.

Mnemonic: SGP 66, 0, 3.

Binary Form of SGP 66, 0, 3

Field Value

Target address 01

h

Instruction number 09

h

Type 42

h

Motor/Bank 00

h

Value (Byte 3) 00

h

Value (Byte 2) 00

h

Value (Byte 1) 00

h

Value (Byte 0) 03

h

Checksum 4F

h

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Read entire documentation.