User Manual

Table Of Contents

- 1 Features

- 2 Order Codes

- 3 Mechanical and Electrical Interfacing

- 4 Connectors

- 5 Jumper Settings

- 6 LEDs

- 7 Communication

- 8 Functional Description

- 9 Operational Ratings and Characteristics

- 10 Abbreviations used in this Manual

- 11 Figures Index

- 12 Tables Index

- 13 Supplemental Directives

- 14 Revision History

TMCM-1110 Hardware Manual • Hardware Version V2.30 | Document Revision V1.10 • 2017-SEP-06

12 / 26

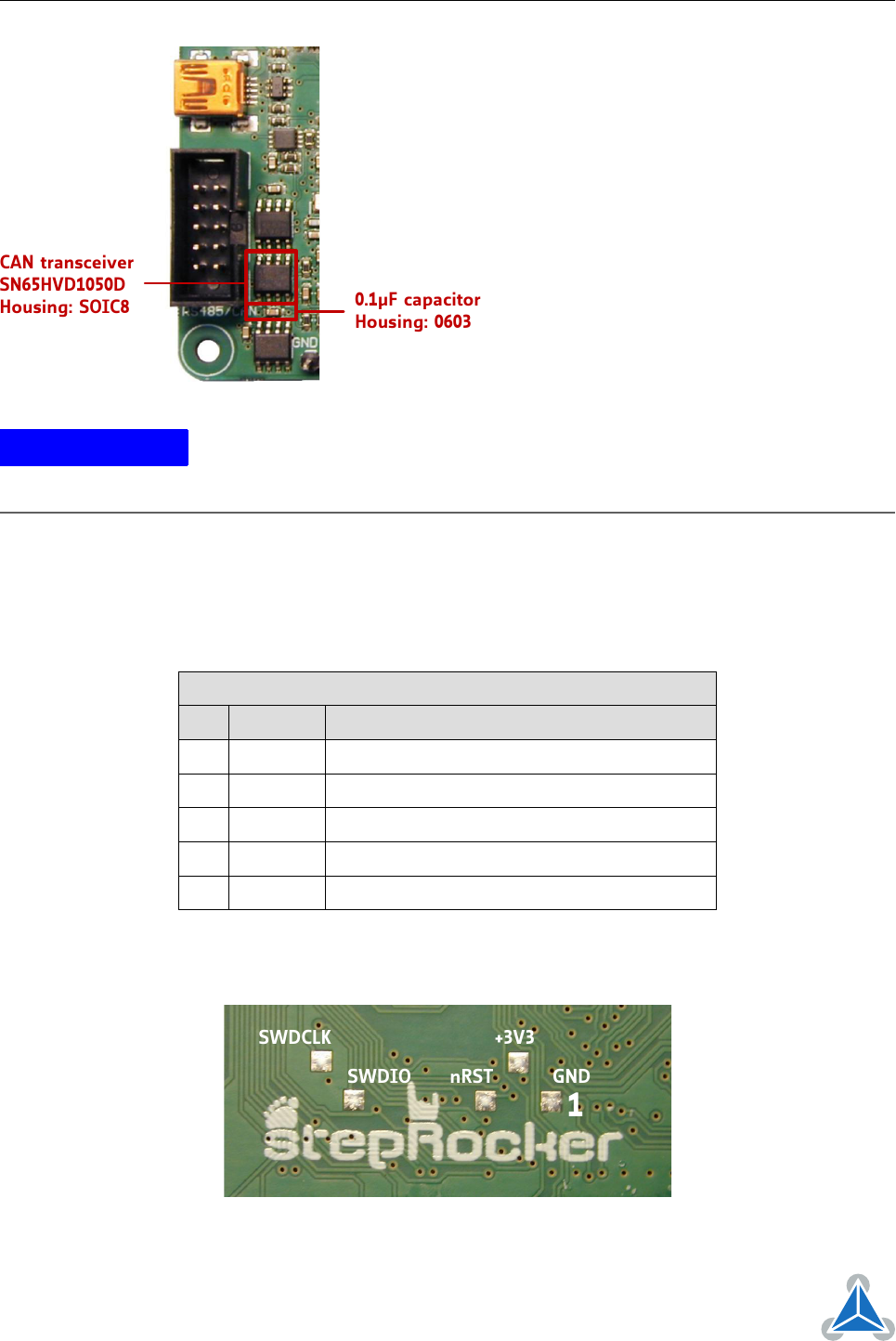

CAN transceiver

SN65HVD1050D

Housing: SOIC8

0.1µF capacitor

Housing: 0603

The table above shows the pin configuration

for CAN, too. Before starting with CAN it

is necessary to solder a SN65HVD1050D

CAN transceiver with housing SOIC8 and a

0.1

µ

capacitor with housing 0603 on the

TMCM-1110_V23 stepRocker. Afterwards,

the stepRocker is ready for using the CAN

interface.

Because of the pin assignment CAN and

RS485 can be used at the same time.

Please note: it is not necessary to remove

the RS485 transceiver.

NOTICE

Note

For setting the

step pulse length

global parameter

86

is used. Adjust this

parameter with the

SGP

command. Refer to the TMCL Firmware Manual of the

stepRocker for further information.

4.9 Microcontroller Programming Interface

The programming pads for the microcontroller are located on the bottom side of the module. They are

connected directly to the related processor pins - resp. GND or on-board generated +3V3 supply. These

pins are used for programming of the bootloader and firmware during production + testing of the module.

Programming Pads

Pin Label Description

1 GND Module and signal ground

2 +3V3 +3V3 DC supply - generated on-board

3 nRST Hardware reset input

4 SWDIO Serial wire data I/O

5 SWDCLK Serial wire clock

Table 11: Programming Pads on Bottom of the PCB

SWDCLK

nRST

+3V3

GND

1

SWDIO

©2017 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com