User Manual

Table Of Contents

- 1 Features

- 2 First Steps with TMCL

- 3 TMCL and the TMCL-IDE — An Introduction

- 3.1 Binary Command Format

- 3.2 Reply Format

- 3.3 Standalone Applications

- 3.4 The ASCII Interface

- 3.5 TMCL Command Overview

- 3.6 TMCL Commands by Subject

- 3.7 Detailed TMCL Command Descriptions

- 3.7.1 ROR (Rotate Right)

- 3.7.2 ROL (Rotate Left)

- 3.7.3 MST (Motor Stop)

- 3.7.4 MVP (Move to Position)

- 3.7.5 SAP (Set Axis Parameter)

- 3.7.6 GAP (Get Axis Parameter)

- 3.7.7 STAP (Store Axis Parameter)

- 3.7.8 RSAP (Restore Axis Parameter)

- 3.7.9 SGP (Set Global Parameter)

- 3.7.10 GGP (Get Global Parameter)

- 3.7.11 STGP (Store Global Parameter)

- 3.7.12 RSGP (Restore Global Parameter)

- 3.7.13 RFS (Reference Search)

- 3.7.14 SIO (Set Output)

- 3.7.15 GIO (Get Input)

- 3.7.16 CALC (Calculate)

- 3.7.17 COMP (Compare)

- 3.7.18 JC (Jump conditional)

- 3.7.19 JA (Jump always)

- 3.7.20 CSUB (Call Subroutine)

- 3.7.21 RSUB (Return from Subroutine)

- 3.7.22 WAIT (Wait for an Event to occur)

- 3.7.23 STOP (Stop TMCL Program Execution – End of TMCL Program)

- 3.7.24 SCO (Set Coordinate)

- 3.7.25 GCO (Get Coordinate)

- 3.7.26 CCO (Capture Coordinate)

- 3.7.27 ACO (Accu to Coordinate)

- 3.7.28 CALCX (Calculate using the X Register)

- 3.7.29 AAP (Accu to Axis Parameter)

- 3.7.30 AGP (Accu to Global Parameter)

- 3.7.31 CLE (Clear Error Flags)

- 3.7.32 EI (Enable Interrupt)

- 3.7.33 DI (Disable Interrupt)

- 3.7.34 VECT (Define Interrupt Vector)

- 3.7.35 RETI (Return from Interrupt)

- 3.7.36 Customer specific Command Extensions (UF0…UF7 – User Functions)

- 3.7.37 Request Target Position reached Event

- 3.7.38 TMCL Control Commands

- 4 Axis Parameters

- 5 Global Parameters

- 6 Module Specific Hints

- 7 Hints and Tips

- 8 TMCL Programming Techniques and Structure

- 9 Figures Index

- 10 Tables Index

- 11 Supplemental Directives

- 12 Revision History

PD-1160 TMCL

™

Firmware Manual • Firmware Version V1.42 | Document Revision V1.06 • 2018-JAN-09

94 / 113

•

To read out or to change the position value of the encoder use axis parameter #216. To read out the

position of the internal encoder use GAP 216, 0. The encoder position register can also be changed

using command SAP 216, 0, <n>, with n = -2147483648 . . . 2147483647.

• Axis parameter #217 is used to change the encoder settings. This also includes the prescaler of the

encoder. The prescaler is used to match motor resolution and encoder resolution.

•

The motor can be stopped automatically if motor position and encoder position differ too much

(deviation error). This can be set using axis parameter #218 (maximum deviation). Setting this

parameter to 0 turns off this feature.

Using the prescaler the encoder counter increments / decrements can be aligned to the position (microstep)

counter. This is essential when using the deviation error supervision (axis parameter #218) and simplifies

encoder counter versus position/microstep counter comparisons (1:1).

number_of_microsteps_per_motor_rotation = prescaler · encoder_ticks_per_rotation

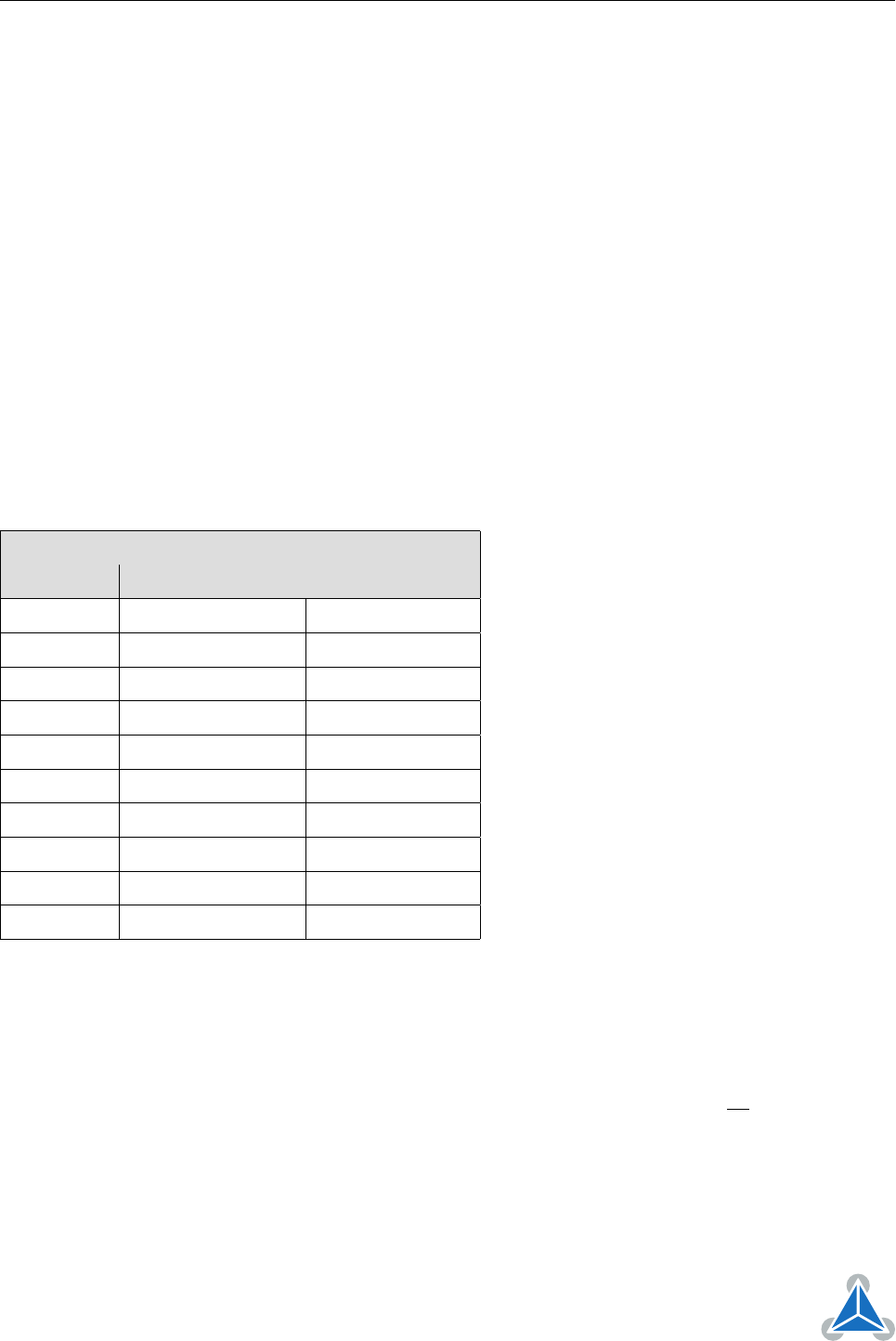

Table 21 shows a subset of encoder prescaler values that can be selected. Other values can also be used,

but the bits 2. . . 4 must not be used for the prescaler because they are needed to select special encoder

functions.

If you are not sure about the resolution of the encoder, use a prescaler of 1 (SAP 217, 0, 512) and then let

the motor run exactly one round to see how far the encoder is counting then.

Encoder Prescaler Values

Value (<p>) Resulting prescaler SAP command

64 0.125 SAP 217, 0, 64

128 0.25 SAP 217, 0, 128

256 0.5 SAP 217, 0, 256

512 1 SAP 217, 0, 512

1024 2 SAP 217, 0, 1024

2048 4 SAP 217, 0, 2048

4096 8 SAP 217, 0, 4096

8192 16 SAP 217, 0, 8192

16384 32 SAP 217, 0, 16384

32768 64 SAP 217, 0, 32768

Table 21: Encoder Prescaler Values

Encoder resolutions are often (but not always) given in lines per rotation (lpr) by the manufaturer of the

encoder. Convert this value to counts per rotation (cpr) by multiplying it by four (because of the quadrature

interface).

Other values than those given in table 21 are also possible. The resulting prescaler is

p

512

. But please bear

in mind not to use bits 2, 3, and 4 of the value, as they are reserved for other functions.

Not all encoder resolutions can be matched with the motor microstep resolution. We recommend to

choose an encoder with a binary resolution (like 512, 2048, 4096, 32768) when selecting an encoder. There

is always a suitable prescaler for such encoders.

©2018 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com