User Manual

Table Of Contents

- 1 Features

- 2 First Steps with TMCL

- 3 TMCL and the TMCL-IDE — An Introduction

- 3.1 Binary Command Format

- 3.2 Reply Format

- 3.3 Standalone Applications

- 3.4 The ASCII Interface

- 3.5 TMCL Command Overview

- 3.6 TMCL Commands by Subject

- 3.7 Detailed TMCL Command Descriptions

- 3.7.1 ROR (Rotate Right)

- 3.7.2 ROL (Rotate Left)

- 3.7.3 MST (Motor Stop)

- 3.7.4 MVP (Move to Position)

- 3.7.5 SAP (Set Axis Parameter)

- 3.7.6 GAP (Get Axis Parameter)

- 3.7.7 STAP (Store Axis Parameter)

- 3.7.8 RSAP (Restore Axis Parameter)

- 3.7.9 SGP (Set Global Parameter)

- 3.7.10 GGP (Get Global Parameter)

- 3.7.11 STGP (Store Global Parameter)

- 3.7.12 RSGP (Restore Global Parameter)

- 3.7.13 RFS (Reference Search)

- 3.7.14 SIO (Set Output)

- 3.7.15 GIO (Get Input)

- 3.7.16 CALC (Calculate)

- 3.7.17 COMP (Compare)

- 3.7.18 JC (Jump conditional)

- 3.7.19 JA (Jump always)

- 3.7.20 CSUB (Call Subroutine)

- 3.7.21 RSUB (Return from Subroutine)

- 3.7.22 WAIT (Wait for an Event to occur)

- 3.7.23 STOP (Stop TMCL Program Execution – End of TMCL Program)

- 3.7.24 SCO (Set Coordinate)

- 3.7.25 GCO (Get Coordinate)

- 3.7.26 CCO (Capture Coordinate)

- 3.7.27 ACO (Accu to Coordinate)

- 3.7.28 CALCX (Calculate using the X Register)

- 3.7.29 AAP (Accu to Axis Parameter)

- 3.7.30 AGP (Accu to Global Parameter)

- 3.7.31 CLE (Clear Error Flags)

- 3.7.32 EI (Enable Interrupt)

- 3.7.33 DI (Disable Interrupt)

- 3.7.34 VECT (Define Interrupt Vector)

- 3.7.35 RETI (Return from Interrupt)

- 3.7.36 Customer specific Command Extensions (UF0…UF7 – User Functions)

- 3.7.37 Request Target Position reached Event

- 3.7.38 TMCL Control Commands

- 4 Axis Parameters

- 5 Global Parameters

- 6 Module Specific Hints

- 7 Hints and Tips

- 8 TMCL Programming Techniques and Structure

- 9 Figures Index

- 10 Tables Index

- 11 Supplemental Directives

- 12 Revision History

PD-1160 TMCL

™

Firmware Manual • Firmware Version V1.42 | Document Revision V1.06 • 2018-JAN-09

83 / 113

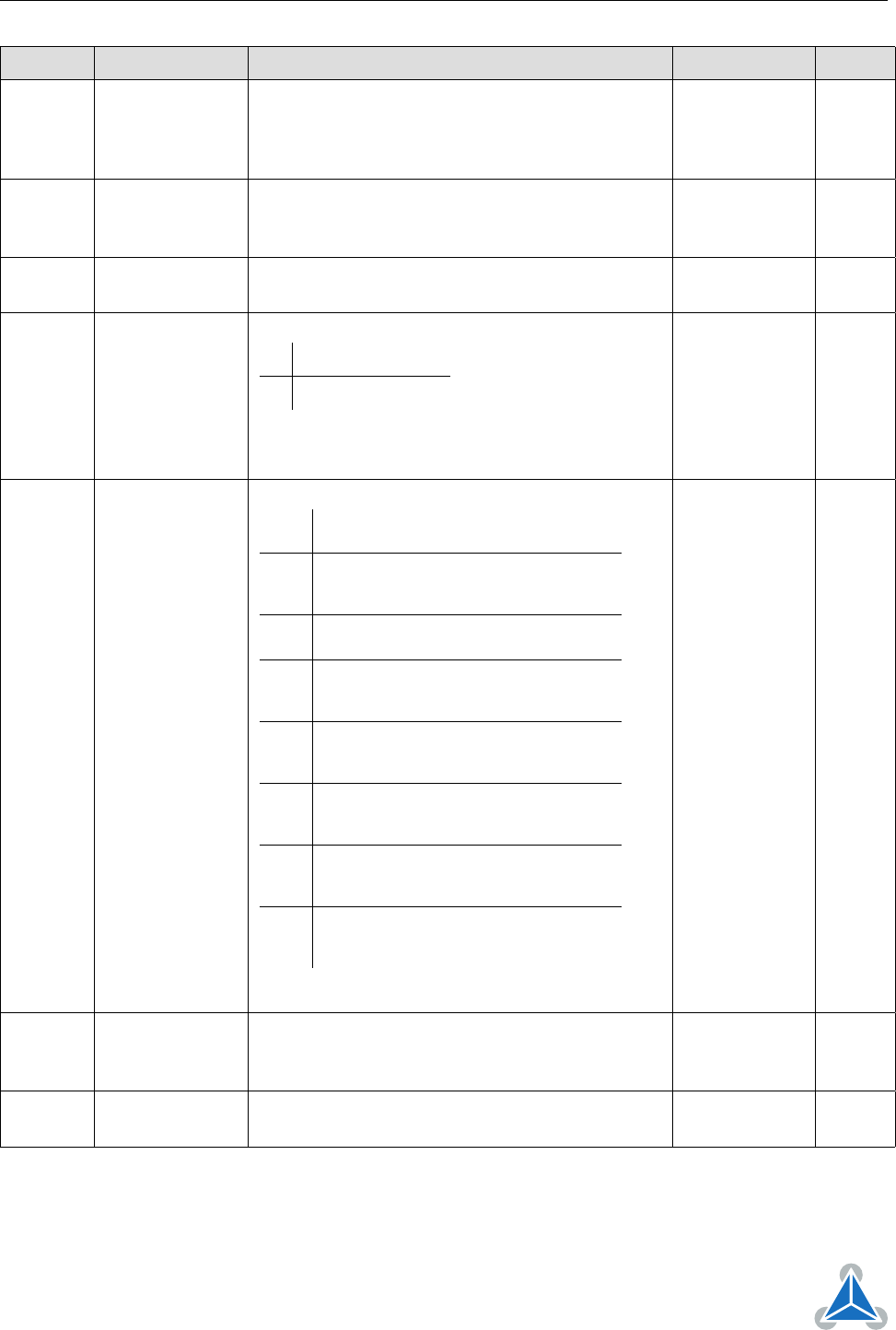

Number Axis Parameter Description Range [Units] Access

200 Boost current

Current used for acceleration and deceleration

phases. If set to 0 the same current as set by

axis parameter #6 will be used. Same scaling as

with axis parameter #6.

0. . . 255 RW

204 Freewheeling

Time after which the power to the motor will be

cut when its velocity has reached zero (a value

of 0 (default setting) means never).

0. . . 65535

[10ms]

RWE

206 Actual load

value

Readout of the actual load value used for stall

detection (stallGuard2).

0. . . 1023 R

207 Extended error

flags

A combination of the following values:

1 stallGuard error

2 deviation error

These error flags are cleared automatically

when this parameter has been read out or when

a motion command has been executed.

0. . . 3 R

208 TMC262 error

flags

A combination of the following values:

Bit 0 stallGuard2 status

(1: threshold reached)

Bit 1 Overtemperature

(1: driver is shut down due to overtemper-

ature)

Bit 2 Overtemperature pre-warning

(1: temperature threshold is exceeded)

Bit 3 Short to ground A

(1: short condition detected, driver cur-

rently shut down)

Bit 4 Short to ground B

(1: short condition detected, driver cur-

rently shut down)

Bit 5 Open load A

(1: no chopper event has happened during

the last period with constant coil polarity)

Bit 6 Open load B

(1: no chopper event has happened during

the last period with constant coil polarity)

Bit 7 Stand still

(1: no step impulse occurred on the step

input during the last 2

20

clock cycles)

Please also refer to the TMC262 Datasheet for more

information.

0. . . 255 R

209 Encoder

position

Encoder counter value. -2147483648

. . . 2147483647

[µsteps]

RW

210 Encoder

prescaler

Prescaler for the encoder. Please see section

6.2.

See section

6.2

RW

©2018 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com