User Manual

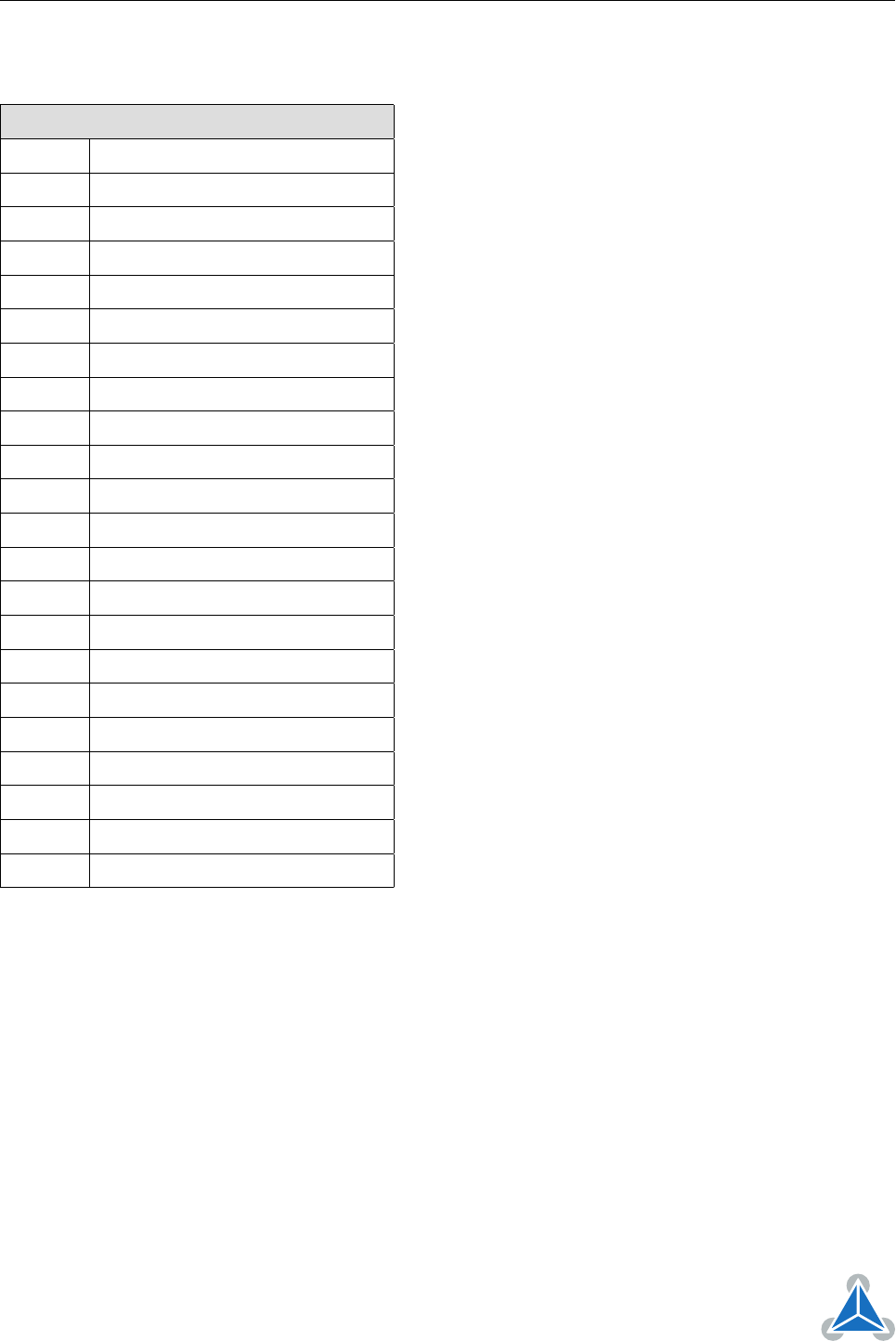

Table Of Contents

- 1 Preface

- 2 Communication

- 3 Communication area

- 3.1 Detailed object specifications

- 3.1.1 Object 1000h: Device Type

- 3.1.2 Object 1001h: Error Register

- 3.1.3 Object 1005h: COB-ID SYNC Message

- 3.1.4 Object 1008h: Manufacturer Device Name

- 3.1.5 Object 1009h: Manufacturer Hardware Version

- 3.1.6 Object 100Ah: Manufacturer Software Version

- 3.1.7 Object 100Ch: Guard Time

- 3.1.8 Object 100Dh: Life Time Factor

- 3.1.9 Object 1010h: Store Parameters

- 3.1.10 Object 1011h: Restore Parameters

- 3.1.11 Object 1014h: COB-ID Emergency Object

- 3.1.12 Object 1015h: Inhibit Time EMCY

- 3.1.13 Object 1016h: Consumer Heartbeat Time

- 3.1.14 Object 1017h: Producer Heartbeat Time

- 3.1.15 Object 1018h: Identity Object

- 3.1.16 Object 1029h: Error Behaviour

- 3.1.17 Objects 1400h – 1403h: Receive PDO Communication Parameter

- 3.1.18 Objects 1600h – 1603h: Receive PDO Mapping Parameter

- 3.1.19 Objects 1800h – 1803h: Transmit PDO Communication Parameter

- 3.1.20 Objects 1A00h – 1A03h: Transmit PDO Mapping Parameter

- 3.1 Detailed object specifications

- 4 Manufacturer specific area

- 4.1 Detailed object specifications

- 4.1.1 Object 2005h: Limit Switches

- 4.1.2 Object 200Dh: Status Flags

- 4.1.3 Object 200Eh: Supply Voltage

- 4.1.4 Object 200Fh: Driver Temperatur

- 4.1.5 Object 2010h: Motor Settings

- 4.1.6 Object 2020h: Limits

- 4.1.7 Object 2030h: Torque Mode Settings

- 4.1.8 Object 2040h: Velocity Mode Settings

- 4.1.9 Object 2050h: Position Mode Settings

- 4.1.10 Object 2055h: Commutation Mode

- 4.1.11 Object 2056h: Velocity Ramp Mode

- 4.1.12 Object 2060h: Open Loop Settings

- 4.1.13 Object 2080h: ABN Encoder Settings

- 4.1.14 Object 2100h: Home Offset Display

- 4.1.15 Object 2702h: Digital Inputs

- 4.1.16 Object 2703h: Digital Outputs

- 4.1.17 Object 2704h: CAN Bit Rate

- 4.1.18 Object 2705h: Node ID

- 4.1.19 Object 2706h: User Variables

- 4.1.20 Object 270Eh: Analog Inputs

- 4.1 Detailed object specifications

- 5 Profile specific area

- 5.1 Detailed object specifications

- 5.1.1 Object 605Ah: Quick Stop Option Code

- 5.1.2 Object 605Bh: Shutdown Option Code

- 5.1.3 Object 605Ch: Disable Operation Option Code

- 5.1.4 Object 605Dh: Halt Option Code

- 5.1.5 Object 605Eh: Fault Reaction Option Code

- 5.1.6 Object 6060h: Modes of Operation

- 5.1.7 Object 6061h: Modes of Operation Display

- 5.1.8 Object 608Fh: Position Encoder Resolution

- 5.1.9 Object 6099h: Homing Speeds

- 5.1.10 Object 60FDh: Digital Inputs

- 5.1.11 Object 6502h: Supported Drive Modes

- 5.1 Detailed object specifications

- 6 Profile Position Mode

- 6.1 Detailed Object Specifications

- 6.2 Detailed Object Specifications

- 6.2.1 Object 6040h: Control Word

- 6.2.2 Object 6041h: Status Word

- 6.2.3 Object 6062h: Position Demand Value

- 6.2.4 Object 6063h: Position Actual Internal Value

- 6.2.5 Object 6064h: Position Actual Value

- 6.2.6 Object 6067h: Position Window

- 6.2.7 Object 606Ch: Velocity Actual Value

- 6.2.8 Object 607Ah: Target Position

- 6.2.9 Object 607Dh: Software Position Limit

- 6.2.10 Object 6081h: Profile Velocity (pp)

- 6.2.11 Object 6082h: End Velocity

- 6.2.12 Object 6083h: Profile Acceleration

- 6.2.13 Object 6084h: Profile Deceleration

- 6.2.14 Object 6085h: Quick Stop Deceleration

- 6.3 How to move a Motor in pp Mode

- 7 Profile Velocity Mode

- 7.1 Detailed Object Specifications

- 7.1.1 Object 6040h: Control Word

- 7.1.2 Object 6041h: Status Word

- 7.1.3 Object 6062h: Position Demand Value

- 7.1.4 Object 6063h: Position Actual Internal Value

- 7.1.5 Object 6064h: Position Actual Value

- 7.1.6 Object 606Ch: Velocity Actual Value

- 7.1.7 Object 607Dh: Software Position Limit

- 7.1.8 Object 6083h: Profile Acceleration

- 7.1.9 Object 6085h: Quick Stop Deceleration

- 7.1.10 Object 60FFh: Target Velocity

- 7.2 How to move a Motor in pv Mode

- 7.1 Detailed Object Specifications

- 8 Homing mode

- 9 Cyclic synchronous Torque Mode

- 10 Emergency Messages (EMCY)

- 11 Figures Index

- 12 Tables Index

- 13 Supplemental Directives

- 14 Revision History

PD42-x-1670 CANopen Firmware Manual • Firmware Version V2.0 | Document Revision V1.0 • 2018-Nov-07

7 / 86

1.2 Abbreviations used in this Manual

Abbreviations

CAN Controller area network

CHGND chassis ground / earth ground

COB Communication object

CST Cyclic synchronous torque mode

FSA Finite state automaton

FSM Finite state machine

NMT Network management

ID Identifier

LSB Least significant bit

MSB Most significant bit

PDO Process data object

PDS Power drive system

RPDO Receive process data object

SDO Service data object

TPDO Transmit process data object

EMCY Emergency object

rw Read and write

ro Read only

hm Homing mode

pp Profile position mode

pv Profile velocity mode

vm Velocity mode

Table 1: Abbreviations used in this Manual

1.3 Firmware Update

The software running on the microprocessor consists of two parts, a bootloader and the CANopen firmware

itself. Whereas the bootloader is installed during production and testing at TRINAMIC and remains un-

touched throughout the whole lifetime, the CANopen firmware can easily be updated by the user. The

new firmware can be loaded into the module via the firmware update function of the TMCL-IDE, using the

RS232 interface of the module. You can also enter boot mode by writing 12345678

h

to object 5FFF

h

and

use the CAN interface for firmware update with the TMCL-IDE.

©2018 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com