Datasheet

Table Of Contents

- XTR108EVM-USB Evaluation Board and Software Tutorial

- 1 Overview

- 2 Hardware Overview

- 3 Hardware Setup

- 3.1 Electrostatic Discharge Warning

- 3.2 Connecting the Hardware

- 3.3 Connecting Power and USB to the USB DAQ Platform

- 3.4 Connecting Loop Power Supply to the XTR108EVM-USB Interface Board

- 3.5 Connecting Outputs to a Digital Multimeter (DMM)

- 3.6 USB DAQ Platform Default Jumper Settings

- 3.7 XTR108EVM-USB Interface Board Default Jumper Settings

- 3.8 XTR108EVM-USB Sensor Board Default Jumper Settings

- 4 Software Setup

- 5 Software Overview

- 6 General Operating Tips

- 7 Hardware Documentation

- 8 Appendix

- Important Notices

Through-holelead

makescontactto

pinsocketwith

springaction.

PINDIA

0.36-0.56

[.014-.022]

SPRING

EYELET

6.60

[.260]

2.54

[.100]

CONTACTPT

MIN

6.27

[.247]MAXPINLENGTH

Hardware Setup

www.ti.com

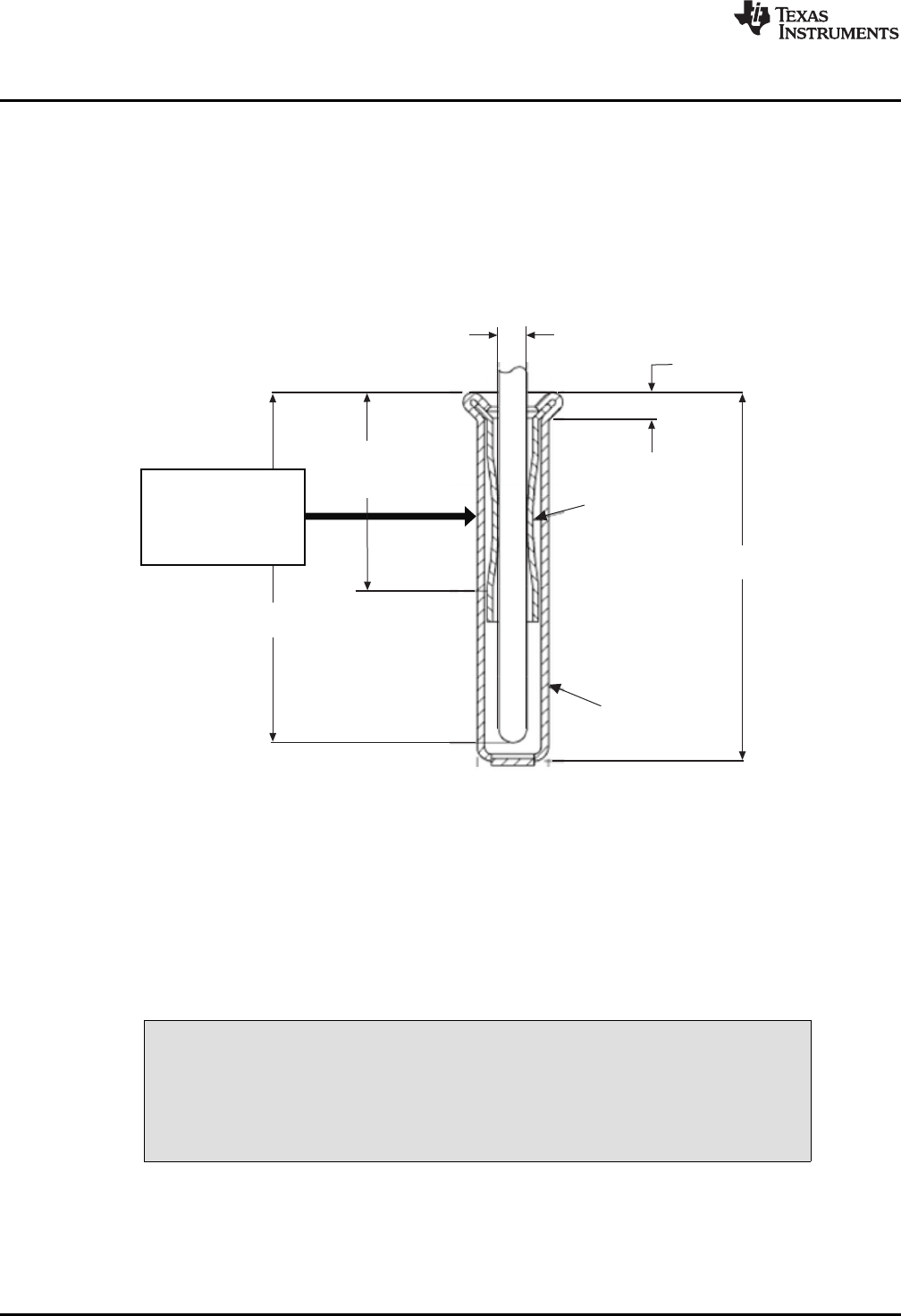

2.3.3 Test Points and Miscellaneous Breadboard Area

There are multiple points available on the Sensor Board, including several connections to I

RET

. I

RET

is

common (labeled as GND on the board) for most XTR108 applications, and is provided for ease of

measuring analog signals. Reserved areas with plated-through, standard-spacing, 0.1-inch holes for

miscellaneous proof-of-concept breadboarding are also provided on the board. Most of the surface-mount

components have pin sockets associated with them. These pin sockets allow the replacement of a

surface-mount component with a through-hole component.

The pin sockets provide good contact with the leads of a component without solder, thus enabling quick

reconfiguration of the board for many different XTR108 designs, as shown in Figure 6.

Figure 6. Pin Socket Mechanical Description

3 Hardware Setup

The XTR108EVM-USB hardware setup involves connecting the three EVM boards together, applying

power to the USB DAQ platform, connecting the USB cable, applying power to the Interface Board, and

setting the jumpers. This section covers the details of this procedure.

3.1 Electrostatic Discharge Warning

CAUTION

Many of the components on the XTR108EVM-USB are susceptible to damage

by electrostatic discharge (ESD). Customers are advised to observe proper

ESD handling precautions when unpacking and handling the EVM, including

the use of a grounded wrist strap at an approved ESD workstation.

16

XTR108EVM-USB Evaluation Board and Software Tutorial SBOU123–March 2012

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated