Manual

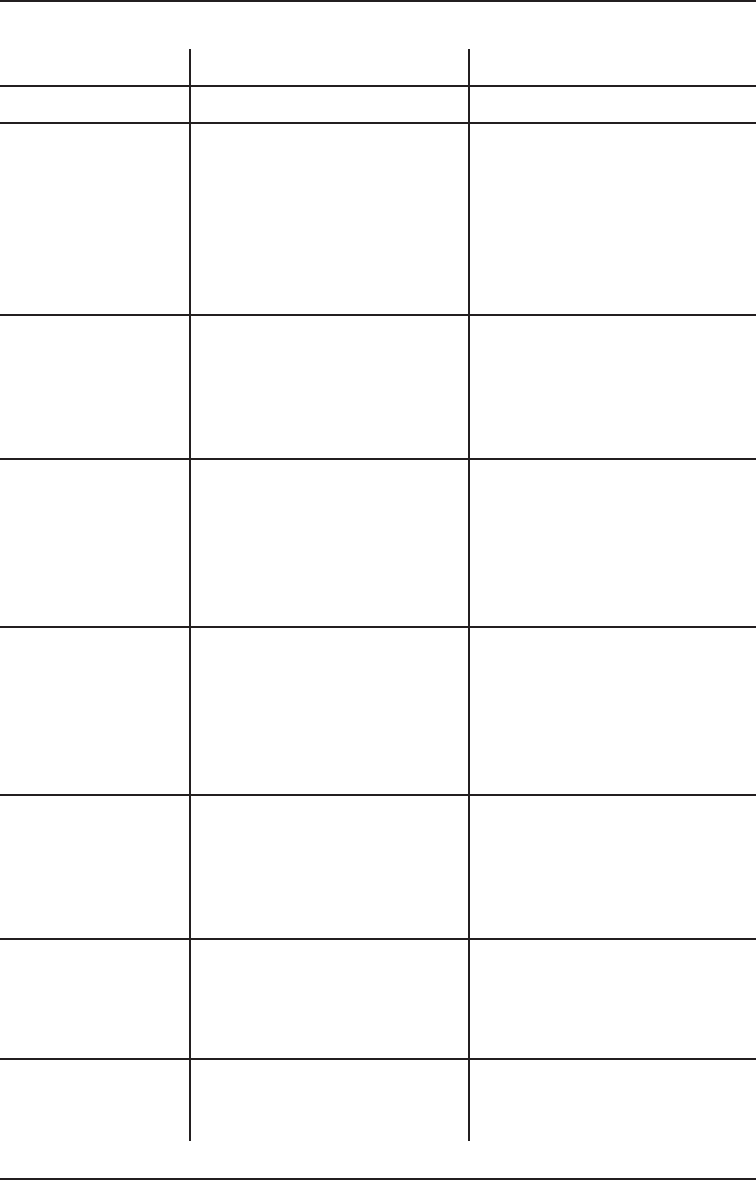

TROUBLESHOOTING CHART

Symptom Possible Cause Corrective Action

Container is cold and 1. Vacuum loss. Check NER. 1. Consult with Taylor-Wharton

may have ice or frost for course of action. Do not

on outer casing. Will attempt to put additional

not hold liquid over- liquid in container.

night. Relief valve is 2. Defective P.B./Economizer 2. Look for P.B. coil pattern in

venting gas. regulator. ice. Close P.B. valve.

Replace or reset regulator.

Ice formation on 1. Pressure building valve 1. Replace or rebuild valve.

bottom of container not closing properly.

when P.B. valve is 2. Leak in pressure 2. Leak test piping

closed. building system connections and tighten

topworks. fittings if needed.

Container vents Pressure Building/ Remove and reset or replace

through relief valve Economizer Regulator set regulator.

when in use. above relief valve setting.

Economizer side of

regulator clogged or

stuck open.

Container vents after This may be caused by Symptom should go away

fill but quits after residual heat vaporizing once container reaches

awhile. some liquid inside operating temperature and

container and is a normal the liquid reaches its

condition. saturation point at container

operating pressure.

Container vents gas Heat leak may be too Perform container

continuously through great. performance evaluation test

relief valve. per Maintenance section to

determine if container

vacuum is adequate.

Level indicator stuck Float rod stuck on or in Reinstall. See Contents

1/2 full. Yellow float rod guide. Gauge Installation.

indicator ring will not

move.

Level indicator at Indicator disengaged from Recouple indicator using

bottom of gauge. gauge rod. Caused by engagement ring.

Container full of dropping the container.

product.