Manual

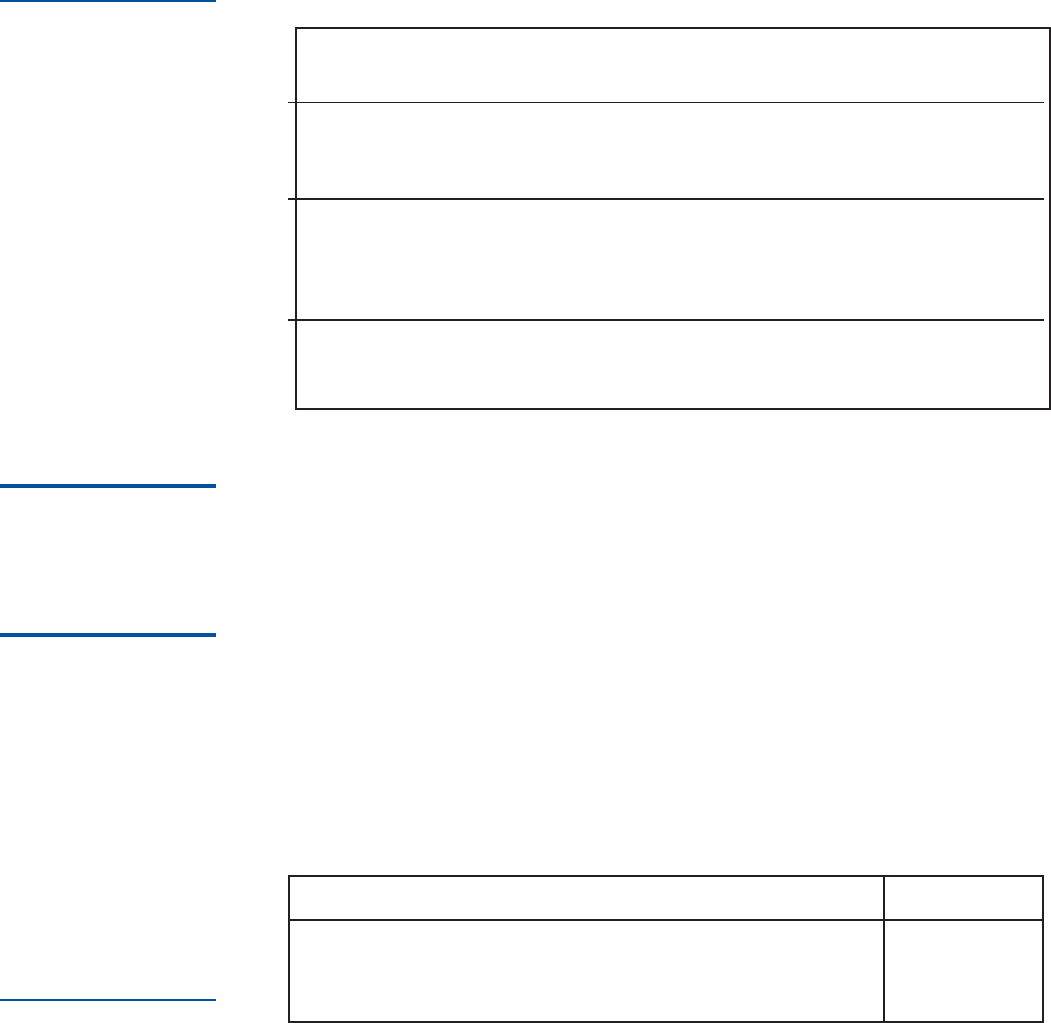

GAS SERVICE CHANGE KITS

Kit Valve Connection

Part No. Gas Service Name Designation

GL50-8C35 Oxygen LIQUID CGA 440

VENT CGA 440

USE CGA 540

GL50-8C30 Nitrogen LIQUID CGA 295

VENT CGA 295

VENT CGA 295

USE CGA 580

GL50-8C31 Argon LIQUID CGA 295

VENT CGA 295

USE CGA 580

REGULATOR MAINTENANCE

A dual stage, spring-loaded regulator is employed for the pressure building/economizer

circuit. This regulator can be adjusted on the container, replaced, or checked and ad-

justed off the container in a readily fabricated bench adjustment fixture.

Regulator Adjustment – On Container

1. Fill the container with the appropriate liquid product.

2. Open the Pressure Building Valve and allow the container pressure to stabilize for

about an hour. Note the point where the pressure stabilizes.

3. Adjust the screw on the top of the regulator to raise or lower the pressure to the

desired point. When decreasing the setting, the pressure building valve must be closed

and the container vented to a lower pressure. Then repeat step 2 in order to observe

the change.

Part No. Normal Setting Range Delta

6999-9015 125 psig 75 to 175 psig 20 psig

8.6 bar 5 to 12 bar 1.4 bar

862 kPa 517 to 1207 kPa 138 kPa

CAUTION:

When changing gas

service, install the

proper fittings – DO

NOT use adapters. The

following procedures

address the physical

changes to the

container only. For

detailed procedures

on the

decontamination of

the container itself,

refer to CGA pamphlet

C-10 “Changes of

Service for Cylinders

Including Procedures

for Inspection and

Contaminant

Removal.”

NOTE:

One clockwise turn of

the adjustment will

raise the setpoint by

approximately 30 psig

(2 bar/207 kPa). See

the chart below to

determine the range

of adjustment for the

regulator you are

servicing. Do not

attempt to set the

regulator to a pressure

outside of its design

range.