User guide

14

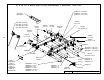

Some tillage implements have close to 180 degrees of wing travel into transport position. Machines like this include

short wing machines with low transport height and 5 section machines (outside wings only). This type of fold

can cause interference problems with SMC Mounted Harrows. The following are steps to prevent problems:

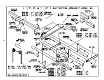

MODEL 74:

1. If mounting brackets/arms hit in transport position, one of the 2 interfering brackets/arms must be moved.

2. If sections hit in transport position, limit travel of top section by:

a. Slide and secure lock collar down support rod a maximum of 3”.

or

b. Replace standard 8H1308 pressure spring with 8H1306.

or

c. Add third mounting arm assembly.

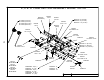

MODEL 94 through 106:

1. If mounting brackets/arms hit in transport position, one of the 2 interfering brackets/arms must be moved.

2. If sections hit in transport position, limit travel of top section by:

a. Slide and secure lock collar down support rod a maximum of 2.5”.

or

b. Add second mounting arm assembly.

or

c. Install travel limit 1/2” x 5” stop bolts* (8X0073) in mounting brackets (8H2120). Secure stop bolt

with 1/2” lock nuts (8X0242), do not over tighten, mounting arm MUST be free to rotate on pivot bolt.

*Stop bolts should be used as a last resort. Extensive frame damage could occur if stop bolts are incorrectly

installed or if eld obstruction causes mounted harrow section to exceed travel limit.

ALWAYS raise machine slowly into transport position the rst time after installing Mounted Harrows, watch for

interference and make adjustments as required.

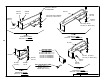

MOUNTING

INSTRUCTIONS

FOR SUMMERS

Mounted Harrows

on Cultivators, Chisel Plows and Disk