user manual

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 27

ASSEMBLY INSTRUCTIONS/OPERATIONS

A BLADE OF PROPER DIMENSIONS IS BEING

UTILIZED. IF THERE ARE ANY QUESTION

REGARDING PROPER BLADE DIMENSIONS FOR

USE WITH THE CRACK SAW, CONTACT THE

CUSTOMER SERVICE DEPARTMENT FOR

SPECIFIC INFORMATION. THERE IS NO

CHARGE FOR THIS SERVICE.

DANGER

STARTING AND/OR RESTARTING THE CRACK

SAW WITH THE DIAMOND BLADE IN DIRECT

CONTACT WITH THE WORK SURFACE CAN

SUBSTANTIALLY REDUCE MACHINE CONTROL,

RESULTING IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

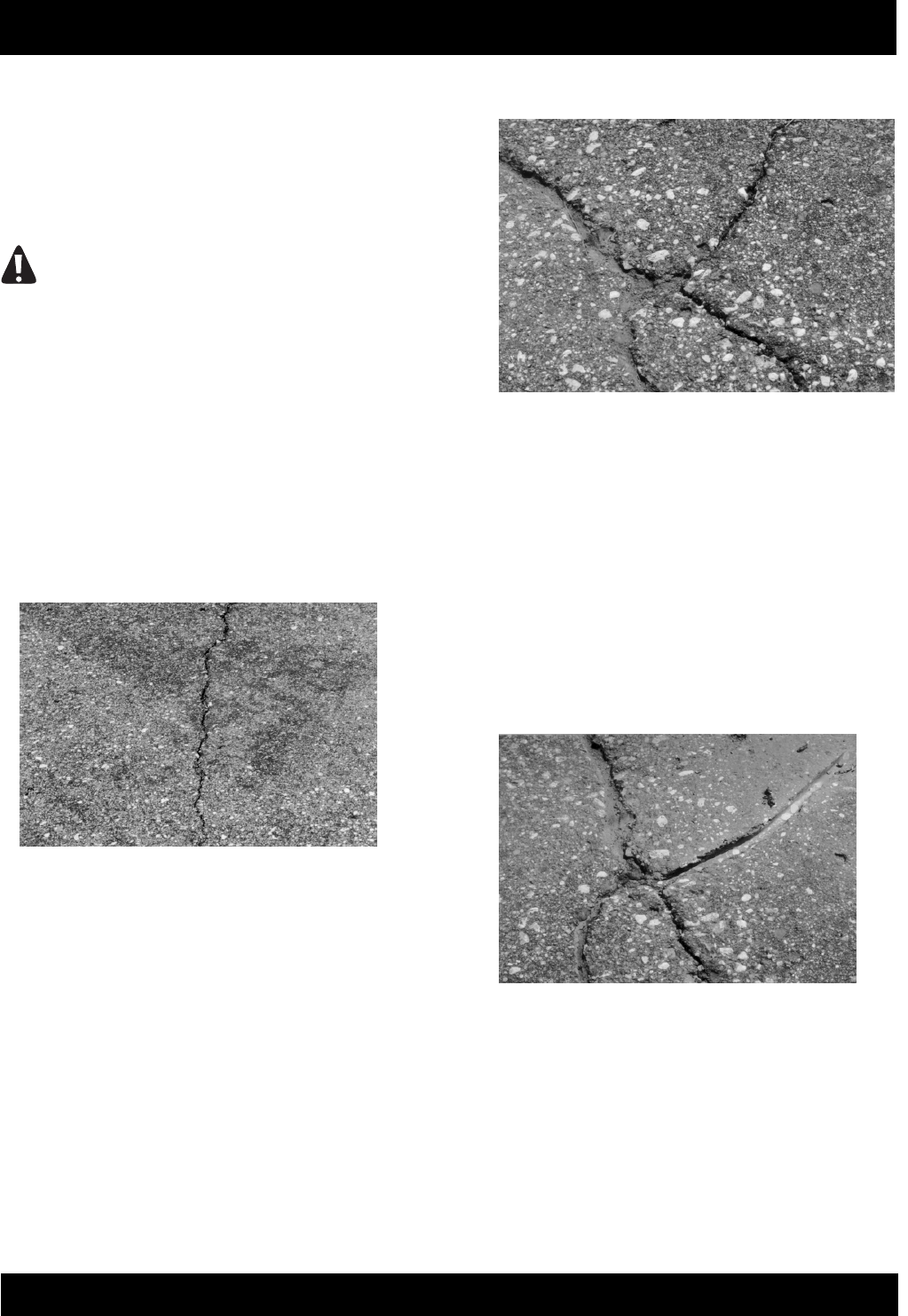

14) Generally speaking, the majority of random

crack patterns follow a predominantly straight line

with no more than 20˚ variance from an imaginary

center line. FIGURE 30. These random crack

patterns are easily sawed to the required widths and

depths by the properly described diamond blades.

FIGURE 30

However, there are many instances where the

random crack pattern follows perpendicular (90˚) to

more obtuse (91˚ to 179˚) angles. FIGURE 31.

These angles will generally not allow the Crack Saw

to properly follow the resulting patterns without

significantly reducing operator control, overall

productivity and causing severe damage the

diamond blade.

FIGURE 31

These types of patterns can be properly sawed by a

multiple step process. A segment of the crack is first

sawed by the described process (FIGURE 32) and

the machine repositioned by the described

procedure to saw the intersecting segment. FIGURE

33. This procedure can be repeated as necessary

by the geometry of the specific random crack

pattern. Following this procedure is especially

important when deep (greater than 1/2 inch) saw

cuts are required for proper crack filling methods. By

utilizing this operating procedure, intricate random

crack patterns can be properly sawed while

maximizing operator control, overall productivity and

extending blade service life.

FIGURE 32