Datasheet

Table Of Contents

- Table 1. Device summary

- 1 Characteristics

- Table 2. Absolute ratings (limiting values)

- Table 3. Thermal resistance

- Table 4. Static electrical characteristics (per diode)

- Figure 1. Average forward power dissipation versus average forward current

- Figure 2. Normalized avalanche power derating versus pulse duration

- Figure 3. Average forward current versus ambient temperature, d = 0.5, (TO-220AC, D2PAK)

- Figure 4. Average forward current versus ambient temperature, d = 0.5, (TO-220FPAC)

- Figure 5. Non repetitive surge peak forward current versus overload duration - maximum values, per diode (TO-220AC, D2PAK)

- Figure 6. Non repetitive surge peak forward current versus overload duration - maximum values (TO-220FPAC)

- Figure 7. Relative variation of thermal impedance junction to case versus pulse duration (TO-220AC, D2PAK)

- Figure 8. Relative variation of thermal impedance junction to case versus pulse duration (TO-220FPAC)

- Figure 9. Reverse leakage current versus reverse voltage applied (typical values)

- Figure 10. Junction capacitance versus reverse voltage applied (typical values)

- Figure 11. Forward voltage drop versus forward current (maximum values)

- Figure 12. Thermal resistance junction to ambient versus copper surface under tab (D²PAK)

- 2 Package Information

- 3 Ordering Information

- 4 Revision history

DocID5387 Rev 11 5/10

STPS8H100 Package Information

10

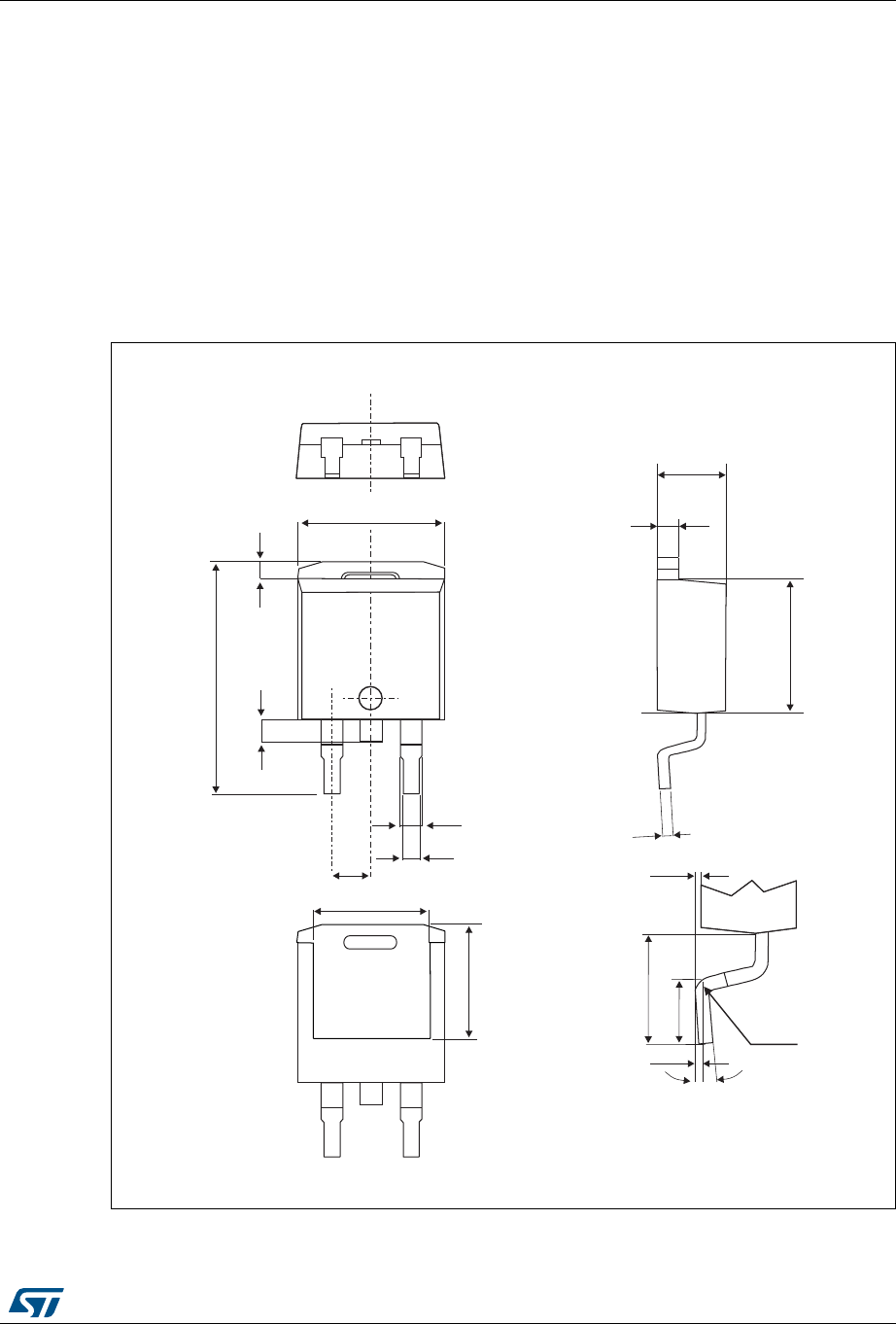

2 Package Information

• Epoxy meets UL94,V0

• Cooling method: by conduction (C)

• Recommended torque value: 0.4 to 0.6 N·m (TO-220AC)

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK

®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

is an ST trademark.

Figure 13. D

2

PAK dimension definitions

e

H

L2

L1

b

b2

E

E1

D1

A

C2

D

A1

0 - 8°

C

L4

L3

L

Gauge

plane