Instruction Manual

Table Of Contents

- 2000 SERIES

- BP2042&BP2062 GRANULATORS

- COPYRIGHT 2006 ALL RIGHTS RESERVED PART NO. CI044120

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TOPIC/SECTION PAGE

- Cutting chamber access …………...…………………………………………..6-7

- Knife sharpening..………….…………………………………………………...6-9

- SECTION 7-TROUBLESHOOTING

- Overview………………………...……….……………………………….….…….7-1

- Test equipment

- Locating trouble

- Troubleshooting chart

- Processing faults..…………………………………………………………..………7-2

- Mechanical faults ………………………………………………………………….7-3

- Electrical faults…………………………………………………………………….7-4

- SECTI0N 8 -PARTS LISTS AND DRAWINGS

- INTRODUCTION

- MACHINE PARTS AND CONTROLS

- MACHINE PARTS AND CONTROLS

- MACHINE PARTS AND CONTROLS

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- OPERATION

- OPERATION

- OPERATION

- OPERATION

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- TROUBLESHOOTING

- TROUBLESHOOTING

- TROUBLESHOOTING

- PARTS LIST AND DRAWINGS

- PARTS LIST AND DRAWINGS

- Rotor Positioning/Locking Assembly Drawing No.CI044115

- GA Non Sound Enclosed STERLING Drawing No.CI044063

- GA Non Sound Enclosed Hyd Opening STERLING Drawing No.CI044063-1

- GA Non Sound Enclosed Conveyor Feed STERLING Drawing No.CI044122

- Regrind Chart 10 Series – Steep Angle STERLING Drawing No.CI044141

- COPYRIGHT 2006 ALL RIGHTS RESERVED PART NO. CI044120

REVISION 9/04 BJF

61

MAINTENANCE

SECTION 6-4

Screen Replacement

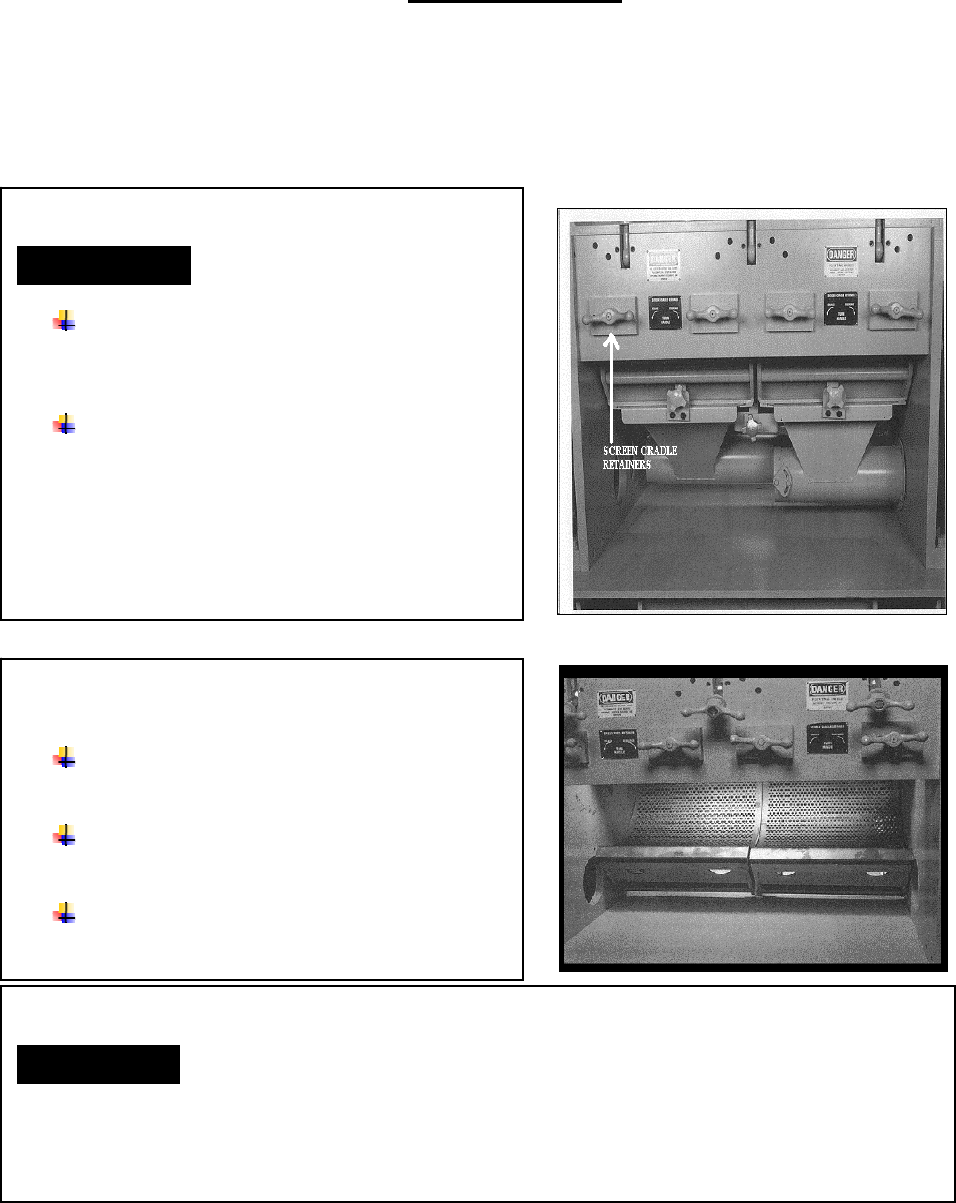

RETRACT THE SCREEN CRADLE

RETAINERS

Turn the screen cradle retainer knobs

clockwise until they stop. (This retracts the support

wedges from beneath the screen cradle).

When the wedges are fully retracted, rods

extend so that their ends are flush with the surface

of each of the retaining knobs mounting plates.

Push down on the bar handle to pivot the

cradle, exposing the screens.

LOWER THE SCREEN CRADLE

WARNING!

The screen cradle sections are held in place

with wedge type retainers at the front of the

machine.

Gas springs are also used to assist in pivoting

the cradle assembly.

BEWARE OF ROTOR KNIVES

CAUTION!

Avoid contact with the rotor knives, which are just above the screen. The cutting edges are very sharp.

Wear gloves to avoid injury when working in this area.