Instruction Manual

Table Of Contents

- 2000 SERIES

- BP2042&BP2062 GRANULATORS

- COPYRIGHT 2006 ALL RIGHTS RESERVED PART NO. CI044120

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TOPIC/SECTION PAGE

- Cutting chamber access …………...…………………………………………..6-7

- Knife sharpening..………….…………………………………………………...6-9

- SECTION 7-TROUBLESHOOTING

- Overview………………………...……….……………………………….….…….7-1

- Test equipment

- Locating trouble

- Troubleshooting chart

- Processing faults..…………………………………………………………..………7-2

- Mechanical faults ………………………………………………………………….7-3

- Electrical faults…………………………………………………………………….7-4

- SECTI0N 8 -PARTS LISTS AND DRAWINGS

- INTRODUCTION

- MACHINE PARTS AND CONTROLS

- MACHINE PARTS AND CONTROLS

- MACHINE PARTS AND CONTROLS

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- OPERATION

- OPERATION

- OPERATION

- OPERATION

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- TROUBLESHOOTING

- TROUBLESHOOTING

- TROUBLESHOOTING

- PARTS LIST AND DRAWINGS

- PARTS LIST AND DRAWINGS

- Rotor Positioning/Locking Assembly Drawing No.CI044115

- GA Non Sound Enclosed STERLING Drawing No.CI044063

- GA Non Sound Enclosed Hyd Opening STERLING Drawing No.CI044063-1

- GA Non Sound Enclosed Conveyor Feed STERLING Drawing No.CI044122

- Regrind Chart 10 Series – Steep Angle STERLING Drawing No.CI044141

- COPYRIGHT 2006 ALL RIGHTS RESERVED PART NO. CI044120

REVISION 9/04 BJF

60

MAINTENANCE

SECTION 6-4

Screen Replacement

WORK SAFELY

TURN OFF AND LOCKOUT the power per OSHA 1910.147 OR ANSI Z244.1-1982

(Lockout/Tag-out of Energy Sources).

If it is not possible to lock out the power, have an electrician remove the fuses.

Make sure the rotor has come to a complete stop.

Wear safety gloves to protect against injury from the rotor and bed knives.

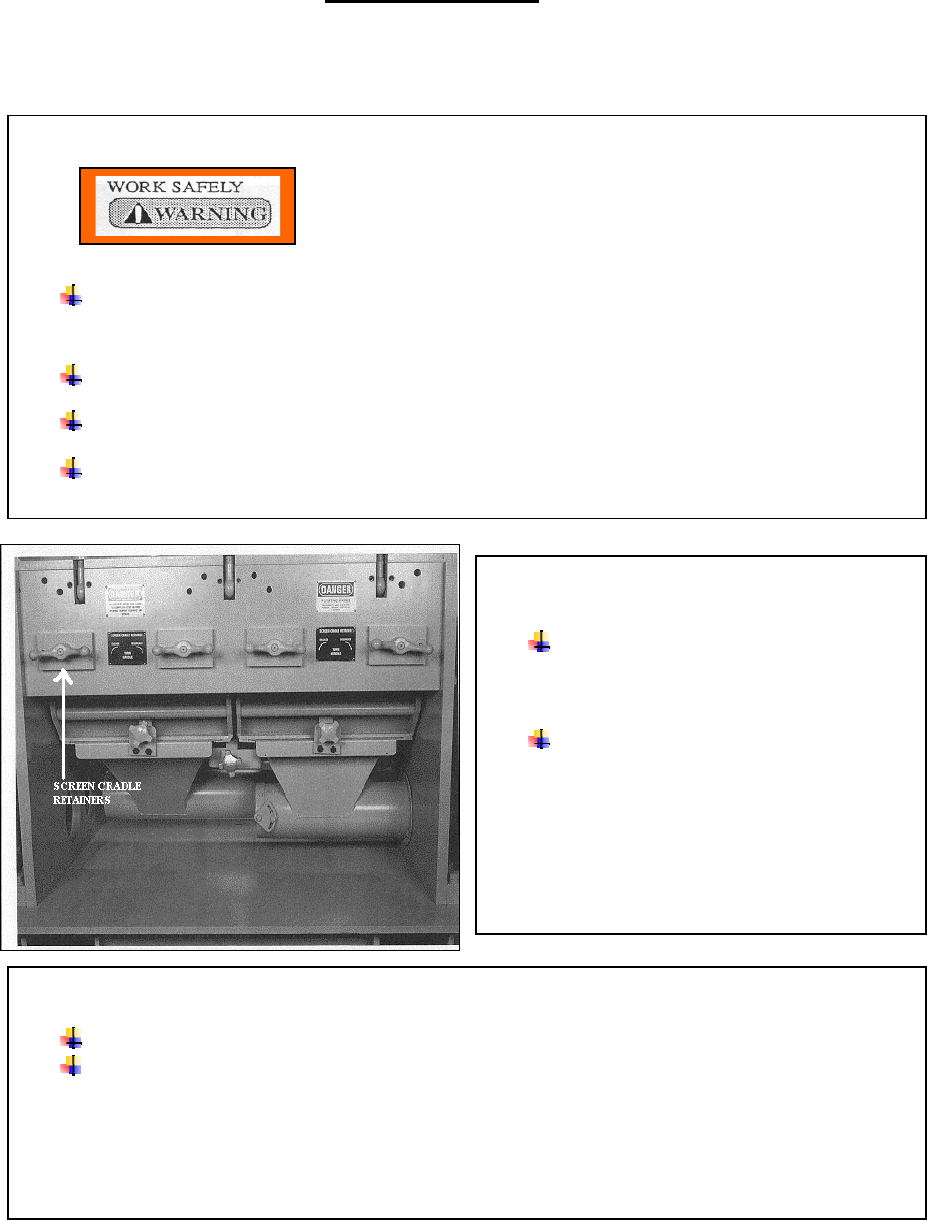

OPEN THE SCREEN CRADLE

INTERLOCK

Disengage the Interlock actuator screw

by turning the knob at the center of the

chute assembly counterclockwise.

Make sure the end of the actuator

screw is visible and clear of any contact.

When disengaged, the interlock opens the

electrical control circuit to the motor and

prevents the machine from running.

REMOVE THE DISCHARGE

Unscrew the knobs holding the right & left side discharge chutes.

Remove each chute by pulling them out toward the front of the machine.