Instruction Manual

Table Of Contents

- 2000 SERIES

- BP2042&BP2062 GRANULATORS

- COPYRIGHT 2006 ALL RIGHTS RESERVED PART NO. CI044120

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TABLE OF CONTENTS

- TOPIC/SECTION PAGE

- Cutting chamber access …………...…………………………………………..6-7

- Knife sharpening..………….…………………………………………………...6-9

- SECTION 7-TROUBLESHOOTING

- Overview………………………...……….……………………………….….…….7-1

- Test equipment

- Locating trouble

- Troubleshooting chart

- Processing faults..…………………………………………………………..………7-2

- Mechanical faults ………………………………………………………………….7-3

- Electrical faults…………………………………………………………………….7-4

- SECTI0N 8 -PARTS LISTS AND DRAWINGS

- INTRODUCTION

- MACHINE PARTS AND CONTROLS

- MACHINE PARTS AND CONTROLS

- MACHINE PARTS AND CONTROLS

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- INSTALLATION

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- SETTINGS AND ADJUSTMENTS

- OPERATION

- OPERATION

- OPERATION

- OPERATION

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- MAINTENANCE

- TROUBLESHOOTING

- TROUBLESHOOTING

- TROUBLESHOOTING

- PARTS LIST AND DRAWINGS

- PARTS LIST AND DRAWINGS

- Rotor Positioning/Locking Assembly Drawing No.CI044115

- GA Non Sound Enclosed STERLING Drawing No.CI044063

- GA Non Sound Enclosed Hyd Opening STERLING Drawing No.CI044063-1

- GA Non Sound Enclosed Conveyor Feed STERLING Drawing No.CI044122

- Regrind Chart 10 Series – Steep Angle STERLING Drawing No.CI044141

- COPYRIGHT 2006 ALL RIGHTS RESERVED PART NO. CI044120

REVISION 9/04 BJF

57

MAINTENANCE

SECTION 6

Periodic Maintenance

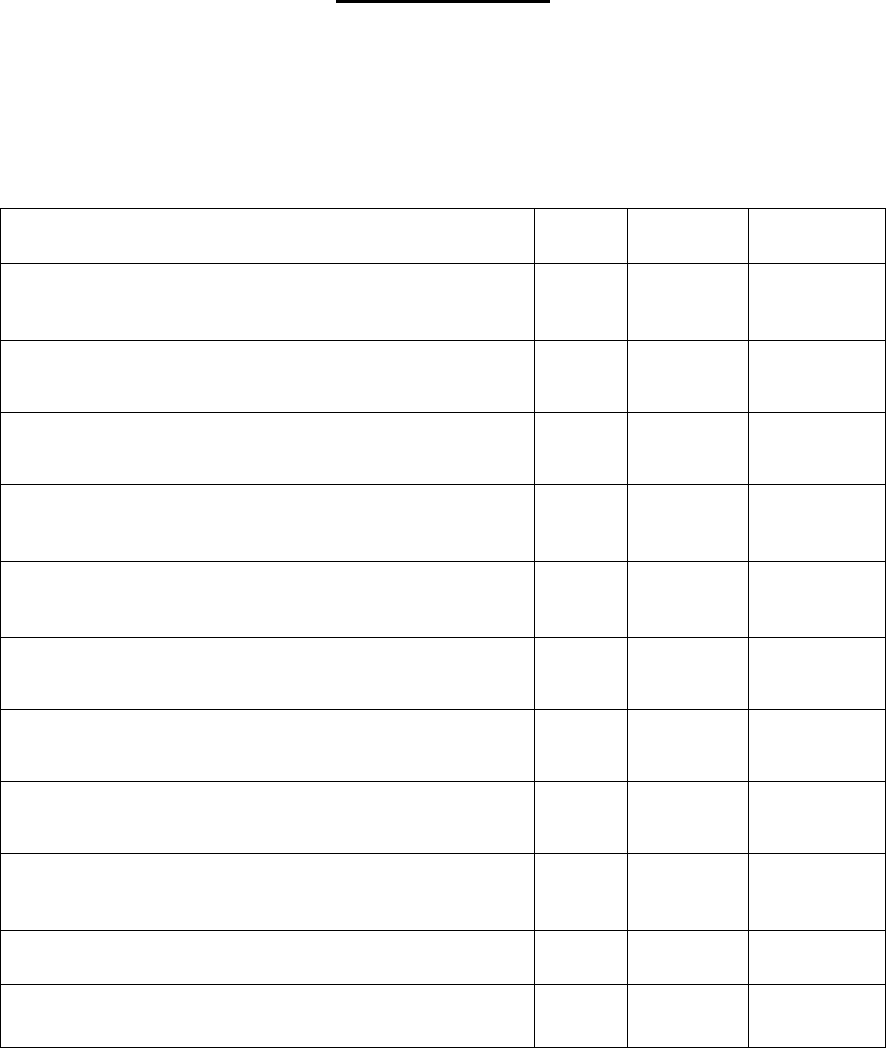

TABLE 1: Periodic Maintenance Schedule

CHECK DAILY WEEKLY MONTHLY

Check tightness of the upper chamber hold down handles.

Refer to Section 6, Cutting Chamber Access

X

Check tightness of the screen chamber wedges.

Refer to Section 6, Screen Replacement

X

Check infeed flap position/condition.

Refer to Section 6, Periodic Maintenance

X

Check the interlock actuator switch screws.

Position/condition. Refer to Section 6, Screen

replacement/Cutting Chamber Access

X

Do housekeeping around work area.

X

Check that the pivot pins and locknuts for jackscrews are

tight. Refer to Section 6, Periodic Maintenance

X

Inspect overall condition of jackscrews.

Refer to Section 6, Periodic Maintenance

X

Check the knife clearance and wear.

Refer to Section 4, Adjusting and Replacing Rotor Knives

X

Check that the rotor and bed knife bolts have proper

torque. Refer to Section 4, Adjusting and Replacing Rotor

Knives and Adjusting and Replacing The Bed Knives

X

Lubrication: More frequent lubrication may be required.

Refer to Section 6, Periodic Maintenance and Lubrication

X

Belt tension: Refer to Section 4, Settings and Adjustments

X