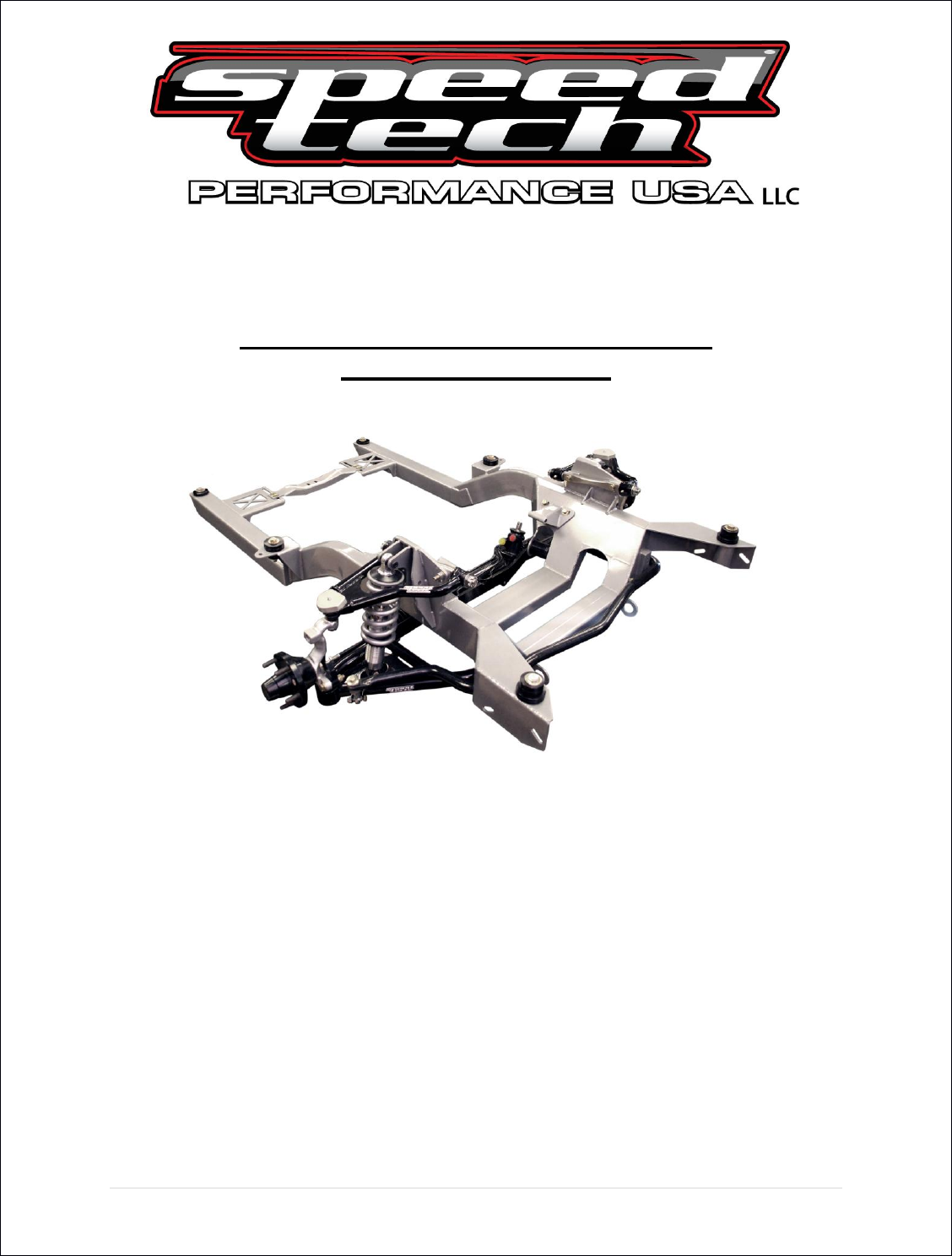

Nov 18, 2013 1967-1969 Camaro and 1968-74 Nova Complete Sub Frame Installation Instructions The following instructions are intended for professional installers and are guidelines only. Speedtech Performance assumes NO responsibility for the installation of any of its products. All products are intended for off road use only and must be installed by qualified professionals only Thank you for purchasing your new Speedtech Sub Frame suspension kit.

Sub Frame Hardware Kit Checklist Sub Frame Instructions -1 Bolts Upper shock mount (2) ½ x 1 ¾ Shoulder bolt Motor mount frame pad (6) 7/16 x 3/4 NF Transmission X member (4) 7/16 x 1 1/4 NF Upper control arm mount (4) 7/16 x 2 1/4 NF Sway bar mounting (4) 3/8 x 1 NF Nylock Nuts 7/16 (8) 3/8 Large Flange (2) Washers 7/16 (22) 3/8 (6) Sway bar mounting hardware is included with the sway bar and the sway bar end links are included with the High Clearance lower control arms.

Assembling the Sub Frame 1. Support the sub frame with jack stands at each corner, be sure it is sturdy and level. 2. Install the supplied motor mounts. Do not fully tighten the bolts at this time to allow adjustment later when installing the engine. Note: LS Series motors use 2 different length frame pads, the Taller Pad must be installed on the Driver Side. This will move the motor over ¾” to clear the oil pan rail. You must also us an LS motor mount adapter such as the ATS # 070001.

3. Install the transmission cross member. Do not fully tighten the bolts at this time to allow adjustment later when installing the engine and transmission. 4. Install the lower control arms. Begin control arm installation by sliding the frame end up into the frame pockets, the straight tube should be located to the rear.

Install only the ½” x 3 ½” front mounting bolt at this time. Apply anti-seize lubricant to the shank of the bolts. The rear bolt will be installed later along with the rack and pinion bracket.

5. Remove Steering rack from packaging. You will not be using the long lower control arm (LCA) mounting bolts that come with the rack hardware. Instead use the Speedtech Grade 8, 4 1/2” long mounting bolts supplied with the control arms. You must remove the rack from the mounting bracket to get the driver side bolt into it's position in the bracket. Apply anti-seize lubricant to the shank of the bolts, install into bracket, then reinstall bracket onto rack body.

The lock nuts that are provided with the lower control arms must be installed through the hole in the bottom of the sub frame, a small amount of red Loctite is suggested. At this time you can torque all 4 lower control arm nuts to 70 ft/ lbs. It is recommended you grease the LCA bushings via the grease fittings at this time. We suggest using Permatex Ultra Slick Synthetic Grease but any high quality chassis grease will do.

6. Assemble the coilover shocks. Start by installing the adjusting nuts threaded to the extreme bottom of the shock. Install the adjusting thrust bearings and washers on top of the nuts prior to the spring. Install spring and spring cap. The spring may need to be compressed in order to get the cap on correctly. Install the supplied T-bar into the bottom bushing of the shock and install the snap rings.

7. Install the lower side of the shock into the lower control arm. You have the option to install the T bar on either the top or the bottom of the mounting pad. Installing it on the bottom will lower the car approximately an additional 1 ¼”. Install the top shock eyelet into the frame bracket. Tighten bolts to 20 ft/lbs.

8. Install the Upper Control Arm (UCA) bolts into the slotted mounting holes. The arm's stainless cross shaft mounts on the inside of the control arm mount bracket, and the short straight tube on the arm should be towards the rear. These holes in the frame are slotted to allow adjustment of the suspension's camber curve. We recommend starting initially with the arms all the way up in the slot. Tighten these bolts as needed and the alignment shop will torque them to specs.

9. Factory spindles can be reinstalled. For optimum performance we recommend using ATS AFX tall spindles. Tighten the lower ball joint to 60 ft/lbs and install the cotter pin. Tighten the upper ball joint to 40 ft/lbs. and install the cotter pin. 10. Install the new steering arms using either your original hardware or new grade 8 hardware. Install the outer tie rod ends into the steering arms, torque to rack and pinion manufacturer specs.

Speedtech Sway Bar Install 11. Installation of the sway bar is basically the same as any standard sway bar. T polyurethane pivot bushings/ mounting hardware are included in the sway bar package. The end link hardware is included with the High Clearance lower control arms. Mount the bar to the sub frame first, bolting the pivot bushing brackets to the vertical pads welded to the front cross member.

12. Before any removal of the old sub frame begins, disconnect and remove the battery, but you knew that. 13. Mark all hoses, lines and cables that pertain to engine, transmission and sub frame removal and disconnect and/ or remove them.

. Once you have removed your original sub frame there are a couple of ways to proceed. If you are using a two post hoist, we recommend you install the motor and transmission into the Speedtech sub frame and then install the completed unit into the car. This allows more room to perform some detail work on the entire assembly without the car's front clip in the way. Engine Install 15. When installing your engine you must use Energy Suspension mount # 3.1114 and transmission mount # 3.1108 or equivalent.

Speedtech offers two types of LSx oil pans for use with our sub frames. Pictured above is the ATS # 70003 LSx Road Race oil pan. It features internal baffling, trap doors and a windage tray. It also features bungs and fittings for remote oil filter mount, oil pressure and temp gauges, and turbo oil line. Pictured below is the ATS # 70004 LS7 and LS9 dry sump oil pans. These pans feature internal passages that maintain the use of a dry sump style oiling system.

If you have not already purchased headers, Speedtech has developed headers specifically for our sub frame that fit Chevrolet LSx, small block and big block series engines. These headers allow the use of a 2 joint rather than a 3 joint steering shaft which improves the responsiveness and overall feel of the steering system. They are also designed to optimize ground clearance for lowered vehicles. 16. Your steering shaft connection will need to be assembled and installed.

Note: It is imperative when setting up and installing the steering shaft that the shaft does not protrude beyond the end of the u-joint housing. Damage and binding will occur if this is not installed properly. The steering shaft is typically left long to allow for trimming. Mock up the shaft assembly in place and trim as needed to ensure that the correct length is achieved. When installing the shaft you MUST offset the u-joints by approximately 45 degrees.

17. The sub frame has alignment holes located in the mid body mounts to facilitate alignment of the sub frame once it is installed in the car, see position 1 in the figure below. Use a long alignment punch to move the sub assembly around and square and align to the body. You must square and align the sub frame in the equalizing the measurements on line “F” and then on line “G”.

Alignment Specifications 67-69 Camaro 68-74 Nova Note: These are only suggestions and may need additional changes to achieve the optimum settings for your driving style or situation.

Terms and Conditions of Sale 1. Effective January, 2008, supersedes all previous policy statements. Policies are subject to change without notice. Speed tech performance Ltd. is not responsible for printing errors. 2. Speed Tech Performance Ltd. does not endorse, nor recommend modification of vehicles for use on public highways, since warranty or government regulations may be violated.