Clock Radio User Manual

Table Of Contents

- CP-UM-5093E-04.pdf

- SAFETY PRECAUTIONS

- Contents

- Chapter 1. GENERAL

- Chapter 2. NAMES & FUNCTIONS OF PARTS

- Chapter 3. MOUNTING

- Chapter 4. WIRING

- 4-1 Wiring Precautions

- 4-2 Compensating Lead

- 4-3 Terminal Connections

- 4-4 Layout of Terminals and Recommended Lead Draw-out Direction

- 4-5 Connecting the Ground and Power Supply

- 4-6 Wiring of Standard and Add-on Terminal Base

- 4-7 Connecting Inputs (analog inputs)

- 4-8 Connecting control outputs (outputs 1, 2)

- 4-9 Connecting auxiliary outputs (outputs 2, 3)

- 4-10 Connecting Event Output (relay output)

- 4-11 Connecting Time Event Output (open-collector)

- 4-12 Connecting External Switch (RSW) Input

- 4-13 Connecting for Communications

- 4-14 Isolating Inputs and Outputs

- Chapter 5. FUNCTIONS

- Chapter 6. OPERATION

- Chapter 7. PARAMETER SETUP

- Chapter 8. PROGRAM SETUP

- Chapter 9. TROUBLESHOOTING

- Chapter 10. SPECIFICATIONS

- Chapter 11. CALIBRATION

- Index

Chapter 4. WIRING

4-9

WARNING

4-8 Connecting control outputs (outputs 1, 2)

Before wiring, or removing/mounting the DCP301, be sure to turn the power

OFF. Failure to do so might cause electric shock.

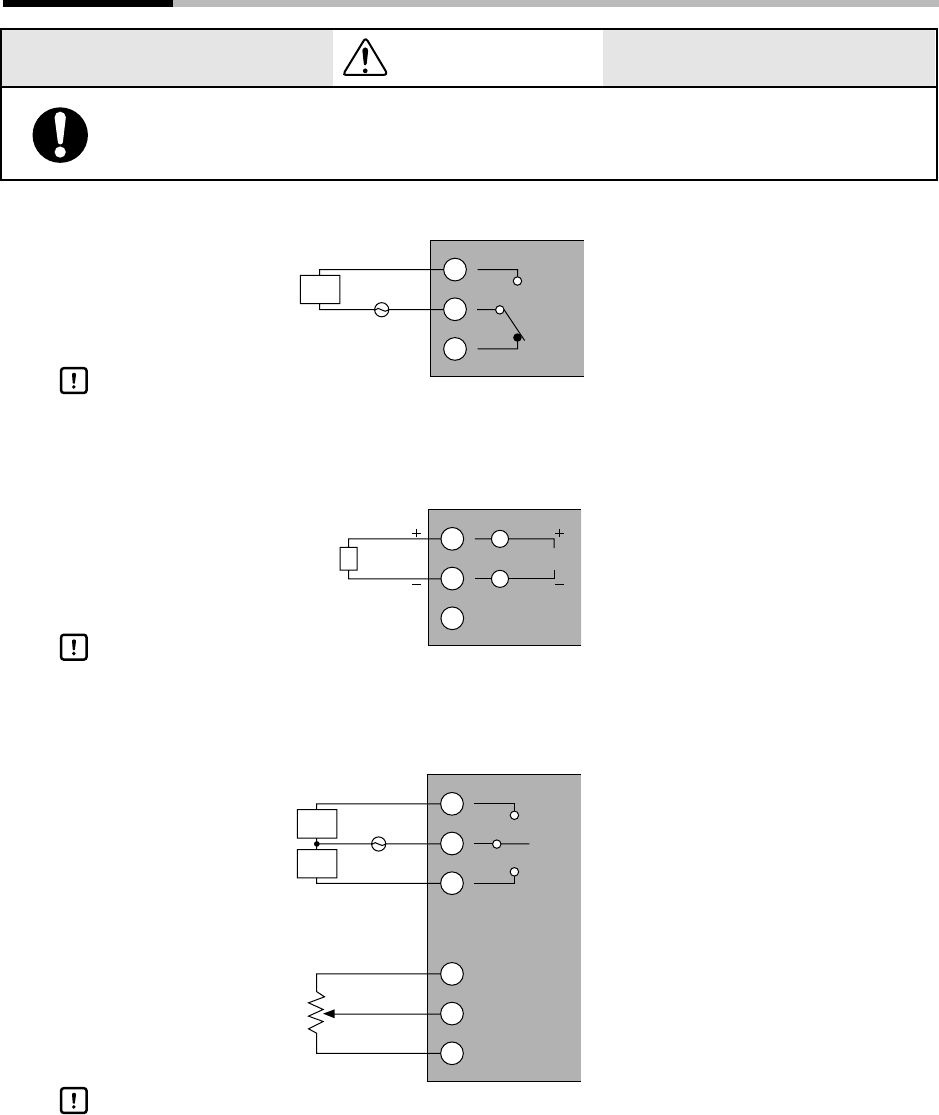

■ Relay output (0D)

Connect as follows.

11

12

13

Load

Power supply

Contact rating, resistive load

5A (30Vdc/120Vac)

4A (240Vac)

Minimum switching current: 100mA

When switching small currents, connect a bleeder resistor to allow current flow of

the minimum relay switching input (100mA min.).

■ Current output (5G)

Connect as follows.

11

12

13

Actuator

4 to 20/0 to 20mAdc

Resistive load 600Ω max.

11

12

13

14

15

16

G

T

Y

1

3

2

Open side

Power supply

Closed side

Open

Closed

Contact rating

4A (120Vac, cosø=0.4)

2A (240Vac, cosø=0.4)

Feedback resistance

100 to 2500Ω

Load

Load

• The life of internal relays is limited.

Avoid setting the PID constant in such a way that results in excessive repeated

ON/OFF switching.

• When using a 100/200Vac motor, pay attention to rush current and the contact

rating. If necessary, provide an external auxiliary relay.

• Separate the wiring for motor terminals (11) (12) (13) and feedback resistor

terminals (14) (15) (16).

(Do not wire the leads in the same duct or use 6-core cable. Doing so might

result in faulty controller operation caused by electrical noise when the motor is

started up.)

• When controlling without motor feedback with variable parameter M .-Cset to

“2”, terminals (14) (15) (16) need not be connected.

4 to 20mAdc and 0 to 20mAdc can be selected in setup data C 9 0.

■ Position-proportional output (2G)

Connect as follows paying attention to the switching direction.

Handling Precautions

Handling Precautions

Handling Precautions